Biological organic fertilizer

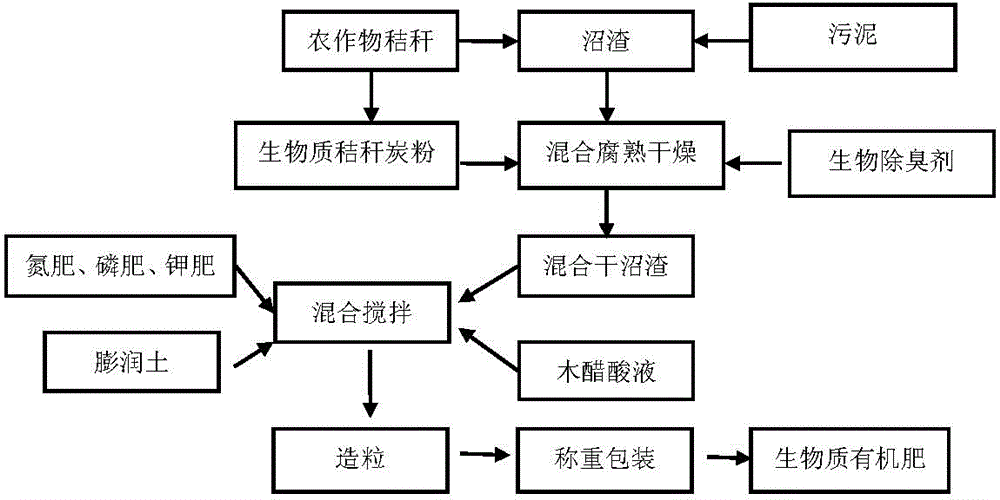

A technology of biological organic fertilizer and organic fertilizer, which is applied in the directions of organic fertilizer, organic fertilizer preparation, inorganic fertilizer, etc., to achieve the effect of convenient application, improved crop yield and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In the specific implementation of the present invention, the organic fertilizer can be calculated by the following weight ratio: 47.86% of biomass straw charcoal powder, 47.86% of biogas residue, 0.08% of bentonite, 1% of nitrogen fertilizer, 1% of phosphate fertilizer, 1% of potassium fertilizer, and biological deodorant 0.2% and 1% wood acetic acid, among them, the crop straw is crushed to 1-5cm, put into the cracking device, and cracked at 300-1100°C to obtain biomass straw charcoal, crushed, and passed through 60-100 mesh Sieve into biomass straw carbon powder; in a solar greenhouse at 19-25°C, mix and stir the biomass straw carbon powder and biogas residue evenly, add biological deodorant, ferment, ferment under ventilation for 7-10 days, and turn over After turning over, continue to ferment for 7-10 days to form a lumpy mixture; crush the lumpy mixture, pass through a 40-mesh sieve, and then add bentonite, nitrogen fertilizer, phosphorus fertilizer, and potassium f...

Embodiment 2

[0018] In the specific implementation of the present invention, the organic fertilizer can also be calculated by the following weight ratio: biomass straw charcoal powder 48%, biogas residue 46.1%, bentonite 0.06%, nitrogen fertilizer 1.8%, phosphate fertilizer 0.8%, potassium fertilizer 1.8%, biological deodorization 0.14% of acetic acid and 1.3% of wood acetic acid, in which, the crop straw is crushed to 1-5cm, loaded into a cracking device, and cracked at 300-1100°C to obtain biomass straw charcoal, crushed, and passed through 60-100 Mesh sieve into biomass straw carbon powder; in a solar greenhouse at 19-25°C, mix and stir the biomass straw carbon powder and biogas residue evenly, add biological deodorant, ferment, and ferment under ventilation for 7-10 days, then turn over Heap, turn over and continue to ferment for 7-10 days to form a blocky mixture; crush the blocky mixture, pass through a 40-mesh sieve, and then add bentonite as a forming aid, nitrogen fertilizer, phosp...

Embodiment 3

[0020] In the specific implementation of the present invention, the organic fertilizer can also be calculated by the following weight ratio: 45.53% of biomass straw charcoal powder, 50% of biogas residue, 0.09% of bentonite, 0.7% of nitrogen fertilizer, 1.9% of phosphate fertilizer, 0.7% of potassium fertilizer, biological deodorization It is made of 0.28% wood acetic acid and 0.8% wood acetic acid. Among them, the crop straw is crushed to 1-5cm, put into a cracking device, and cracked at 300-1100°C to obtain biomass straw charcoal, crushed, and passed through 60-100 Mesh sieve into biomass straw carbon powder; in a solar greenhouse at 19-25°C, mix and stir the biomass straw carbon powder and biogas residue evenly, add biological deodorant, ferment, and ferment under ventilation for 7-10 days, then turn over Heap, turn over and continue to ferment for 7-10 days to form a blocky mixture; crush the blocky mixture, pass through a 40-mesh sieve, and then add bentonite as a forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com