Regular catalyst packing for reactive distillation column

A technology of reactive distillation column and catalytic packing, which is applied in the field of high-efficiency structured catalytic packing, can solve the problems of packing layer blockage, liquid channeling, and insufficient tightness, and achieve the goals of reducing equipment investment costs, increasing reaction conversion rate, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

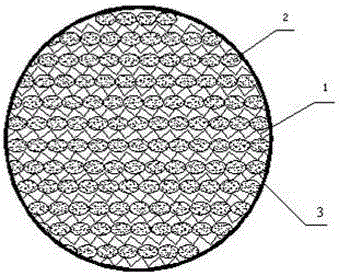

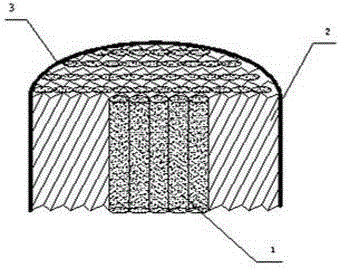

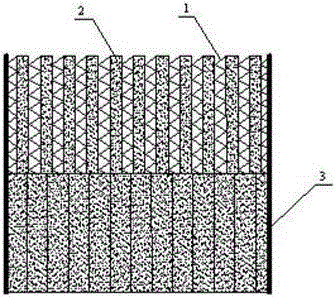

Embodiment 1

[0026] Component A, which uses stainless steel orifice plate corrugated packing as structured catalytic packing, has a pore mesh of 80 mesh, and the inclination direction of the corrugation forms an included angle of 45° with the horizontal direction; component B uses polyester sewed catalyst cloth as the structured catalytic packing , and the cloth bags are sewed into cloth bags with a side-by-side width of 120mm at equal intervals, and glass microspheres are filled in the cloth bags as catalysts, and the filling height is 70% of the cloth bag height. The heights of the catalyst cloth bag and the stainless steel corrugated wire mesh are both 200mm, and the overall length is adjusted according to different positions of the structured catalytic packing. Each layer of structured catalytic packing has 10 pieces of stainless steel corrugated wire mesh and 10 pieces of catalyst cloth bag, 20 pieces in total. Place the stainless steel corrugated wire mesh and catalyst cloth bag alter...

Embodiment 2

[0028] Stainless steel corrugated wire mesh is used as component A of the structured catalytic packing, the mesh number of which is 30 mesh, and the inclined direction of the corrugation is at an angle of 45° to the horizontal direction; the component B made of polypropylene fiber as a catalyst cloth bag is used as the structured catalytic packing , and the cloth bags are sewed into cloth bags with a side-by-side width of 100mm at equal intervals, and then filled with resin as a catalyst in the cloth bag, and its filling height is 80% of the height of the cloth bag. The height of the stainless steel corrugated wire mesh and the catalyst cloth bag is 500mm, and the overall length is adjusted according to the different positions of the structured catalytic packing. Each layer of structured catalytic packing has 15 pieces of stainless steel corrugated wire mesh and 15 pieces of catalyst cloth bags, 30 pieces in total. Place the stainless steel corrugated wire mesh and catalyst clo...

Embodiment 3

[0030] Stainless steel corrugated wire mesh packing is used as component A of the structured catalytic packing, the mesh number of which is 50 mesh, and the inclined direction of the corrugation is at an angle of 60° to the horizontal direction; the catalyst cloth bag sewn with nylon cloth is used as the structured catalytic packing Component B, and the cloth bags are sewn into cloth bags with a side-by-side width of 80 mm, and then filled with molecular sieves as catalysts, and the filling height is 90% of the cloth bag height. The heights of the catalyst cloth bag and the stainless steel corrugated wire mesh are both 300mm, and the overall length is adjusted according to different positions of the structured catalytic packing. There are 10 pieces of stainless steel corrugated wire mesh and 10 pieces of catalyst cloth bag in each layer of structured catalytic packing, 20 pieces in total. The stainless steel corrugated wire mesh and catalyst cloth bag are placed alternately to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com