Food processor with post-fermentation function and preparation method of fermentation raw pulp

A food processor and a technology for fermenting puree, which is applied in the preparation of alcoholic beverages, beverage preparation devices, household appliances, etc., and can solve problems such as fermentation treatment of uncooked soybean milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

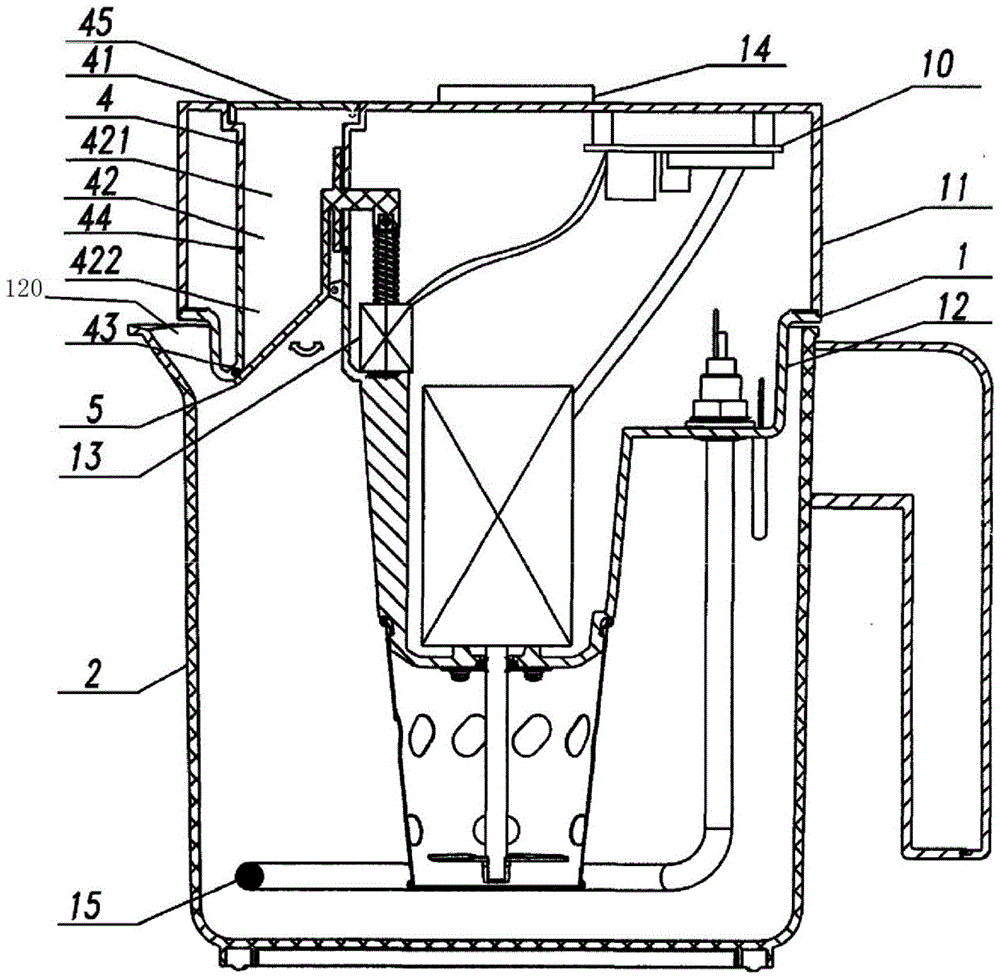

[0128] The production method of the fermented puree provided in this embodiment is to slightly modify the structure of the fully automatic soybean milk machine disclosed in ZL200810237764.7 to become a food processor with a post-fermentation function, and control the electric (electromagnetic ) The actuator puts edible fermented bacteria into the raw food slurry soup to complete the production process. figure 1 It is a schematic diagram of the structure of this automatic soybean milk machine, such as figure 1 As shown, this full-automatic soybean milk machine mainly includes a head 1, a cup body 2 (also called barrel body), a control circuit board 10 and a crushing cutter device. Machine head 1 comprises machine head upper cover 11 and machine head lower cover 12, and machine head 1 is placed on barrel body 2 top, and machine head 1 is also provided with automatic unloading device and button 14, and described automatic unloading device comprises material storage Cavity 4, the...

Embodiment 2

[0139] The method for making fermented puree provided in this example is to modify the control program of an ordinary soymilk machine, add a post-fermentation function, and become a food processor with post-fermentation function, and complete the process of making fermented puree. That is, the structure of the soymilk machine remains unchanged, but the soymilk production control program of the control circuit board on it is changed, and the function of heat preservation and fermentation after the cooked soymilk is made is added. The specific production method is:

[0140] Now take the production of natto puree as an example to illustrate. Put 40 grams of wet soybeans, 30 grams of wet black beans, 1000 ml of water and a Bacillus natto capsule (manufactured by Tianjin Jinnuo Ruilin Biotechnology Development Co., Ltd., Xiao brand Bacillus natto capsule. 0.32 g / capsule) into the soybean milk machine Then turn on the soymilk machine to make mature soymilk according to the normal p...

Embodiment 3

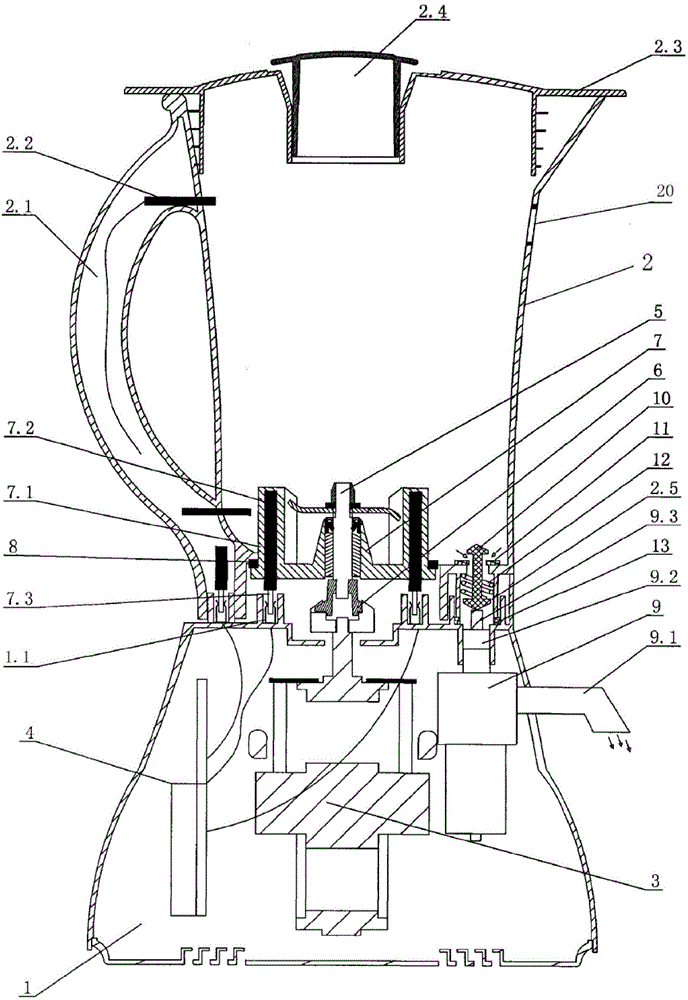

[0151] The production method of the fermented puree provided in this example is to modify the control program of the multifunctional heating mixer disclosed in ZL201110193753.5, and add a post-fermentation function to make it a food processor with a post-fermentation function to complete the production process. figure 2 Schematic diagram of the structure of this multifunctional heating mixer. Such as figure 2 As shown, this multifunctional heating mixer includes a stirring cup 2 (also known as a barrel) arranged on a main body 1 (i.e. a machine base 1), and a motor 3 and a control device 4 (i.e. a control circuit board) are arranged in the main body 1. The motor 3 is coupled to the mixing knife assembly 5 (ie, the crushing tool device) of the stirring cup 2 through the transmission assembly 6, and the bottom of the stirring cup 2 is provided with an opening, and the bottom of the opening is connected with a compression diversion heater 7; the compression diversion heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com