Truss element method without chord members and combined node bridge

A combination and bridge technology, applied in the direction of bridges, truss bridges, bridge forms, etc., can solve the problems of prolonging the construction period, increasing the workload on site, and many processing procedures, so as to achieve the effects of convenient construction and hoisting, shortening the construction period and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

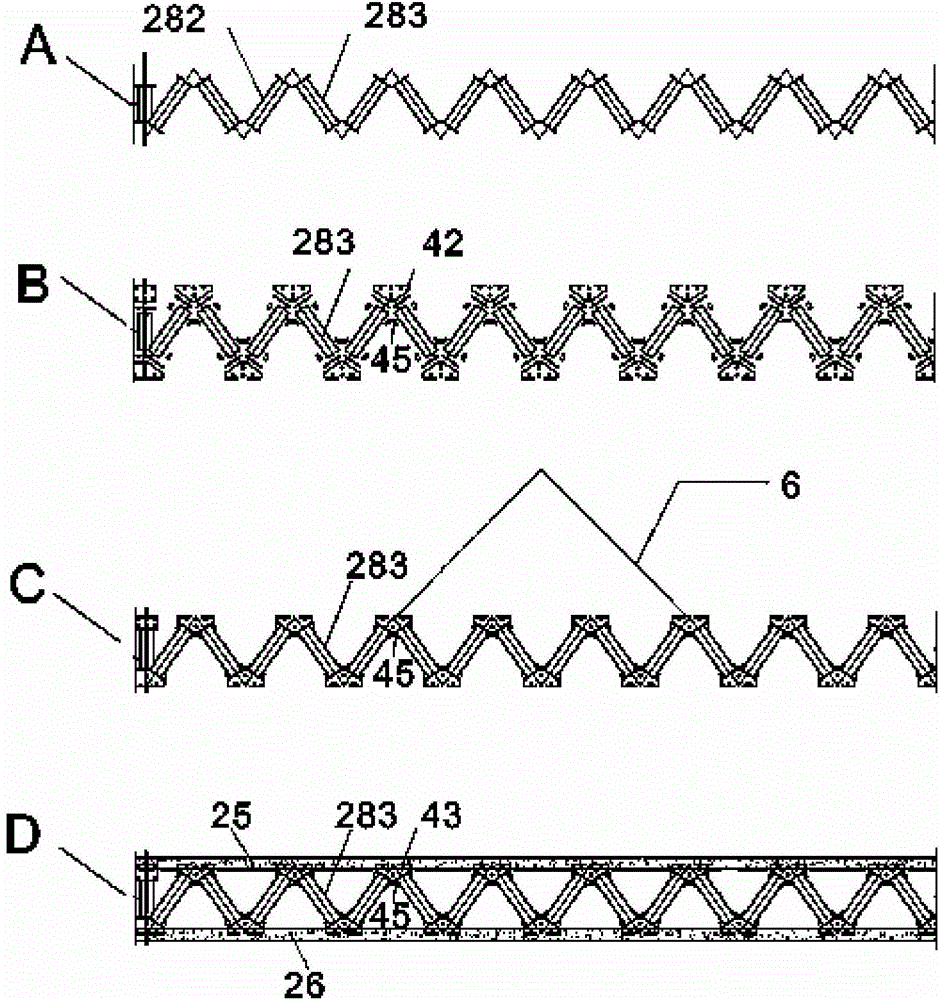

[0043] Please refer to Figure 4 and 5 , this embodiment one includes two stringer tubes 282, 283 (that is, single elements, which can be steel pipe concrete), beam top plate 25 (or beam bottom plate 26), inner conduit 41, embedded plate 42a, shear force connector 43, Shear studs 44, stiffeners 45 and U-shaped steel bars 46.

[0044] The ports at the fixed ends of the two truss tubes 282 and 283 are arranged in a "eight"-shaped structure, and the embedded plate 42a is arranged at the end with a smaller opening in the "eight"-shaped structure, and the fixed ends of each truss tube are fixed with internal The conduit 41 is fixedly connected to the embedded plate 42a through the internal conduit 41, wherein the internal conduit 41 plays the role of auxiliary connection.

[0045] The shear connector 43 can be an S-PBL shear connector 43 or a T-PBL shear connector 43 . The shear connector 43 is in the shape of a plate with holes for reinforcing bars, and is fixedly connected to ...

Embodiment 2

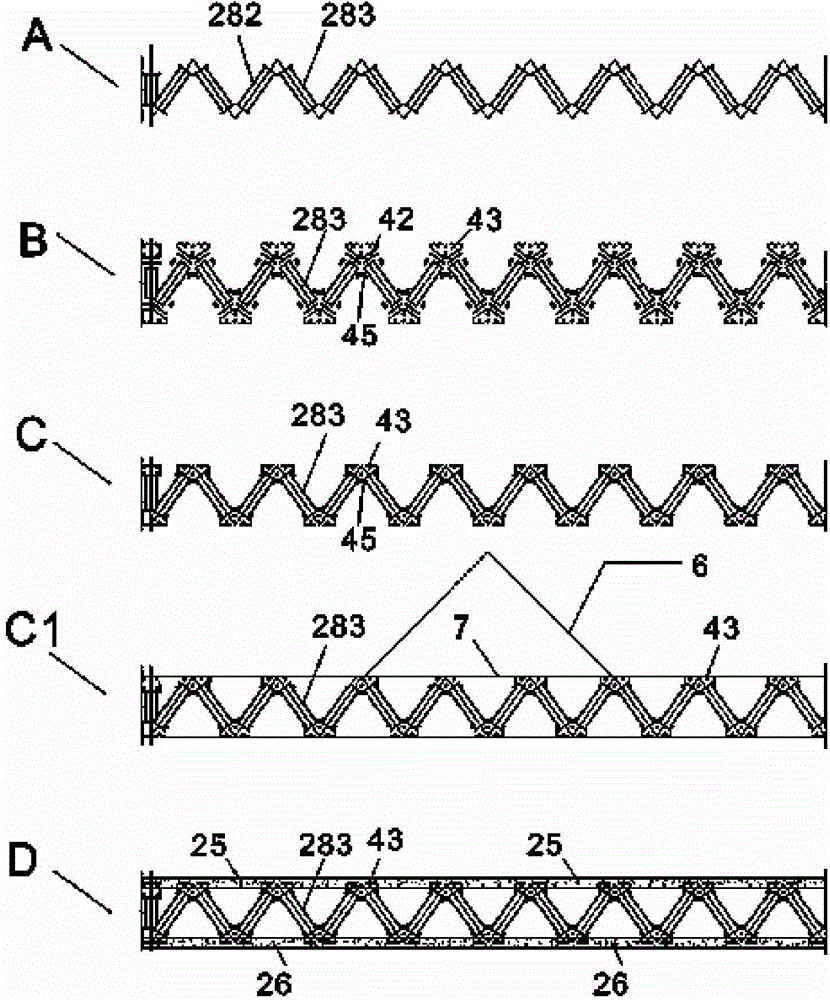

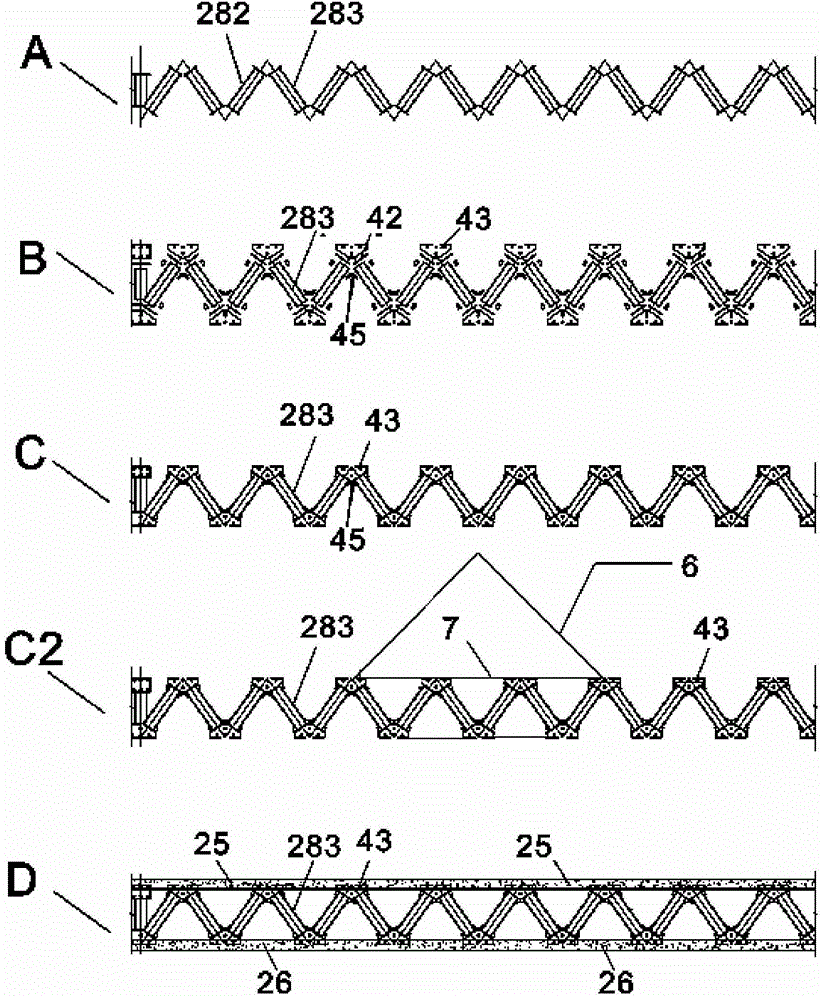

[0050] Please refer to Figure 7 and 8 In the second embodiment, the difference from the first embodiment is that the embedded plates 42b corresponding to the two girder tubes are connected to each other to form an integrated structure.

Embodiment 3

[0052] Please refer to Figure 9 and 10 The difference between the third embodiment and the first embodiment is that, in the integrated joint structure of truss piers provided by the third embodiment, the stiffener plate 45 in the first embodiment is omitted.

[0053] In contrast, the truss-pier combined integral node structure provided by this application can fully solve the stress concentration of nodes, has a single function, and does not require additional coating anti-corrosion protection measures. The internal nodes of the structure are integral, and the force is clearly defined. PBL parts have large shear bearing capacity and good fatigue resistance; and the overall rigidity is good. Discrete unit elements can be formed into an integral truss section, without the need for upper chords and lower chords, which greatly facilitates construction and hoisting, and realizes the construction of steel webs without supports.

[0054] Further, based on the above-mentioned combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com