Ultra-high-speed generator rectifier based on automatic energy consumption matching

A generator and rectifier technology, applied in electrical components, output power conversion devices, DC power input to DC power output and other directions, can solve problems such as energy mismatch, to ensure stable power supply, realize speed limit, and ensure safety Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

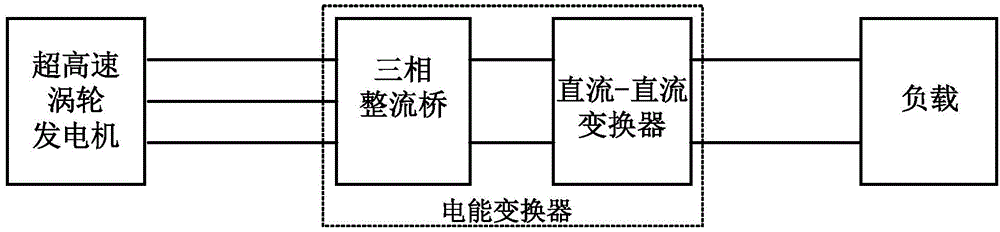

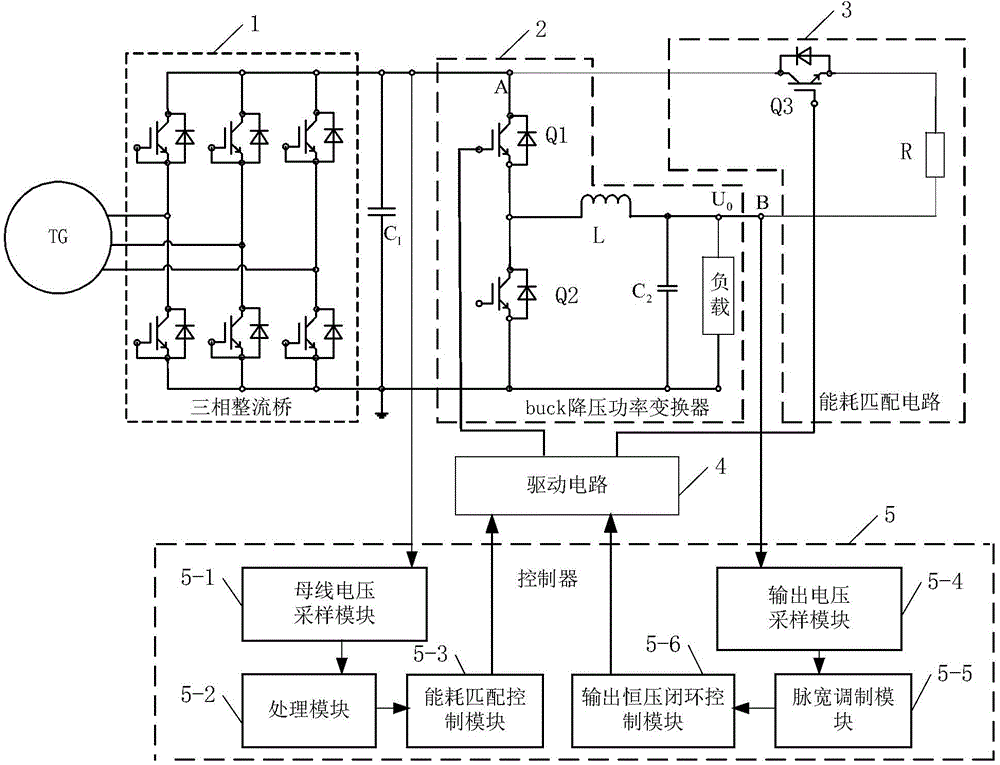

[0050] Specific implementation mode one: see figure 2 Describe this embodiment, a kind of ultra-high-speed generator rectifier based on automatic energy consumption matching described in this embodiment, it is the generator rectifier of series energy consumption matching, it includes three-phase rectifier bridge 1, buck step-down power conversion Device 2, energy consumption matching circuit 3, drive circuit 4, controller 5 and capacitor C on the 1st 1 ;

[0051] Buck step-down power converter 2 includes No. 1 power switch tube Q1, No. 2 power switch tube Q2, inductor L and No. 2 capacitor C 2 ;

[0052] The energy consumption matching circuit 3 includes a No. 3 power switch tube Q3 and a resistor R,

[0053] The three-phase current input terminal of the three-phase rectifier bridge 1 is used to connect with the three-phase current output terminal of the ultra-high-speed generator,

[0054] The output terminal of the positive power supply of the three-phase rectifier brid...

specific Embodiment approach 2

[0073] Embodiment 2: The difference between this embodiment and the ultra-high-speed generator rectifier based on automatic energy consumption matching described in Embodiment 1 is that the controller 5 includes a bus voltage sampling module 5-1 and a processing module 5-2 , energy consumption matching control module 5-3, output voltage sampling module 5-4, pulse width modulation module pulse width modulation module 5-5 and output constant voltage closed-loop control module 5-6;

[0074] The bus voltage signal input terminal of the bus voltage sampling module 5-1 is used as the bus voltage signal input terminal of the controller 5,

[0075] The bus voltage signal output terminal of the bus voltage sampling module 5-1 is connected to the voltage signal input terminal of the processing module 5-2, and the data signal output terminal of the processing module 5-2 matches the data signal input terminal of the energy consumption control module 5-3 connect,

[0076] The control sign...

specific Embodiment approach 3

[0080]Embodiment 3: The difference between this embodiment and the ultra-high-speed generator rectifier based on automatic energy consumption matching described in Embodiment 1 is that the processing module 5-2 is implemented by chip XC822, and the pulse width modulation module The pulse width modulation module 5-5 is realized by chip TL494.

[0081] The control part of the control system of the present invention adopts the TL494 control chip to carry out constant voltage output control and the energy consumption matching circuit controller is realized by the single-chip microcomputer XC822 of Infineon Company. The present invention uses the AD sampling function of the single-chip microcomputer to sample the bus voltage, and generates PWM through the algorithm The wave controls the energy consumption matching switch.

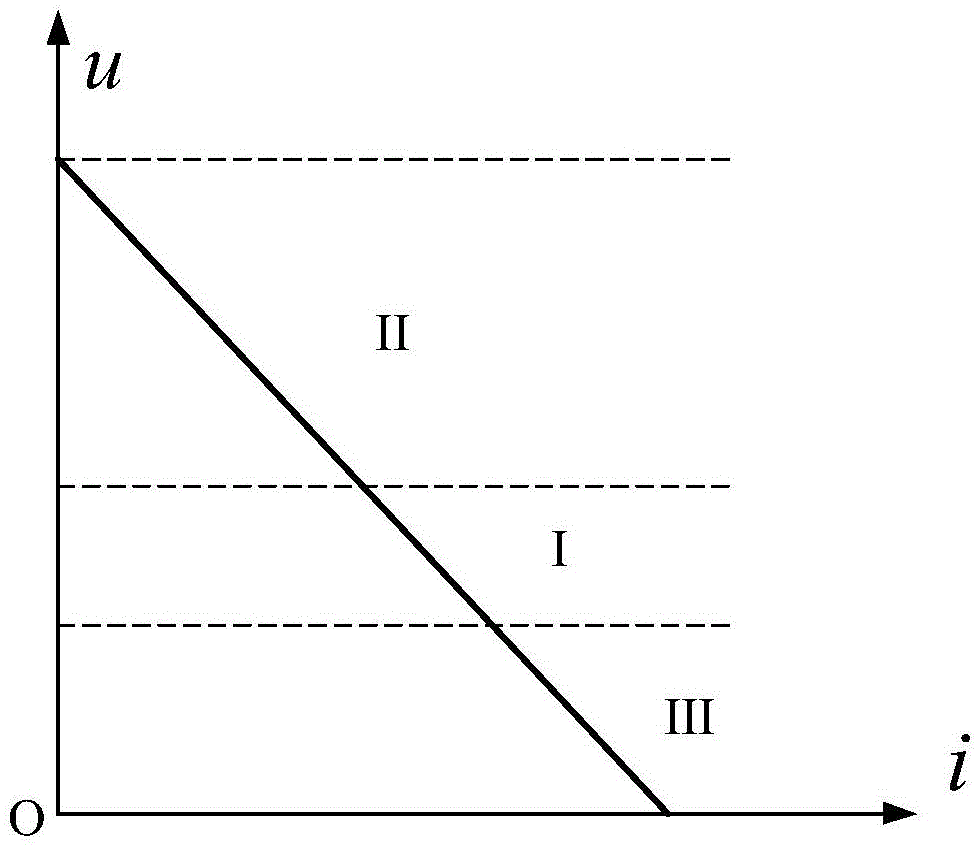

[0082] Its control flow chart is for example Figure 10 As shown, the AD module of the single-chip microcomputer samples the DC bus voltage, and uses the media...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com