Cylinder type permanent magnetic speed controller

A permanent magnet governor, cylindrical technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of small magnetic density, small torque density, low utilization rate of magnetic energy of permanent magnet governor, etc., to achieve large output The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

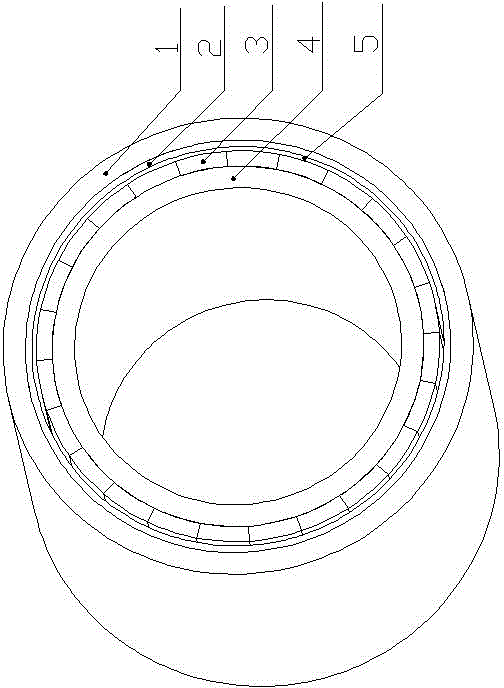

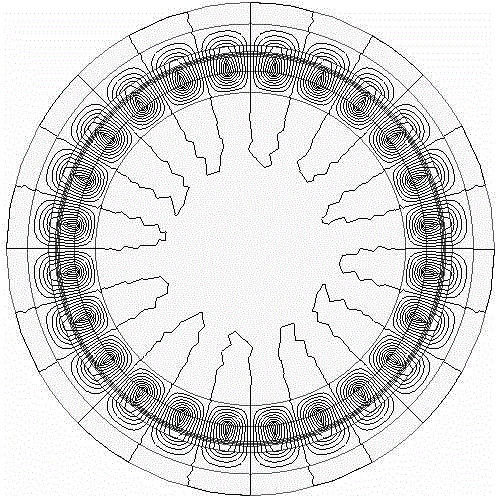

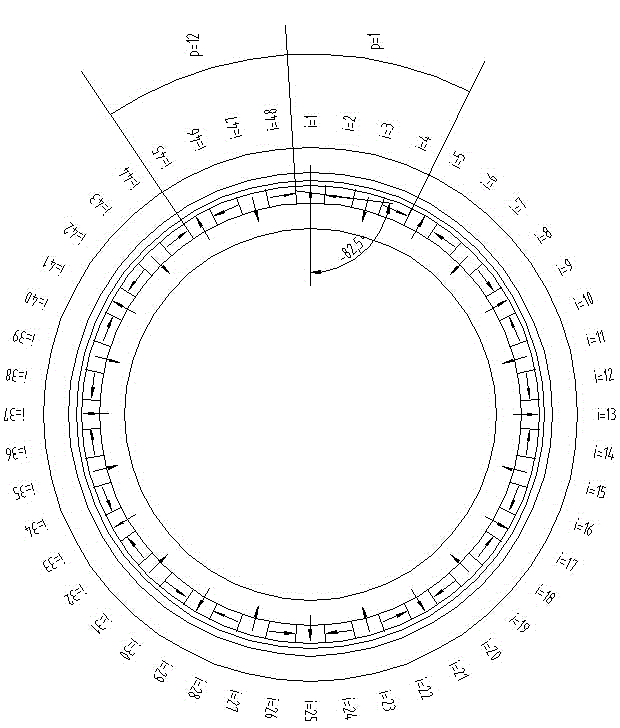

[0030] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 The cylinder type permanent magnet governor shown includes an outer magnetic cylinder 1, a thin-walled copper cylinder 2, a permanent magnet block 3, and an inner magnetic cylinder 4 arranged coaxially and sequentially from the outside to the inside. , The outer wall of the thin-walled copper cylinder 2 is closely attached and fixed to the inner surface of the outer magnetic permeable cylinder 1 to form the first rotor assembly, and a number of permanent magnet blocks 3 are attached and fixed on the outer side of the inner permeable cylinder 4 in the circumferential direction. The surface constitutes the second rotor assembly, the first rotor assembly and the second rotor assembly are coaxially installed, and there is an air gap 5 between the outer surface of the permanent magnet block 3 and the inner surface of the thin-walled copper cylinder 2. The outer magnetic cylinder 1 and the inner mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com