High-voltage sodium-carbon fluoride secondary battery

A secondary battery, carbon fluoride technology, applied in the direction of secondary batteries, battery electrodes, electrochemical generators, etc., can solve the problems of unstable discharge platform, poor cycle performance, low discharge voltage, etc., and achieve good cycle stability , large discharge capacity and high discharge potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The electrochemical performance test of the high-voltage sodium-carbon fluoride secondary battery of the present invention is carried out by using the prepared 2025 button-type sodium battery, and the positive carbon fluoride electrode is prepared by the paste coating method. The specific steps are to dissolve carbon fluoride, acetylene black and binder in a solvent according to the mass ratio of carbon fluoride positive electrode material: acetylene black: binder = 80:10:10, mix them by ball milling, and apply them on the treated aluminum foil , dried in vacuum at 120°C, and pressed for molding at 30MPa. A positive electrode for a sodium battery was obtained.

[0041] The binder can be polyacrylic acid (PAA), polyvinylidene fluoride (PVDF), LA-132 (produced by Chengdu Yindile Power Technology Co., Ltd.), carboxymethylcellulose sodium salt (CMC), etc. at least one of the

[0042] The solvent is at least one of nitrogen-methylpyrrolidone (NMP), acetone, deionized water...

Embodiment 2

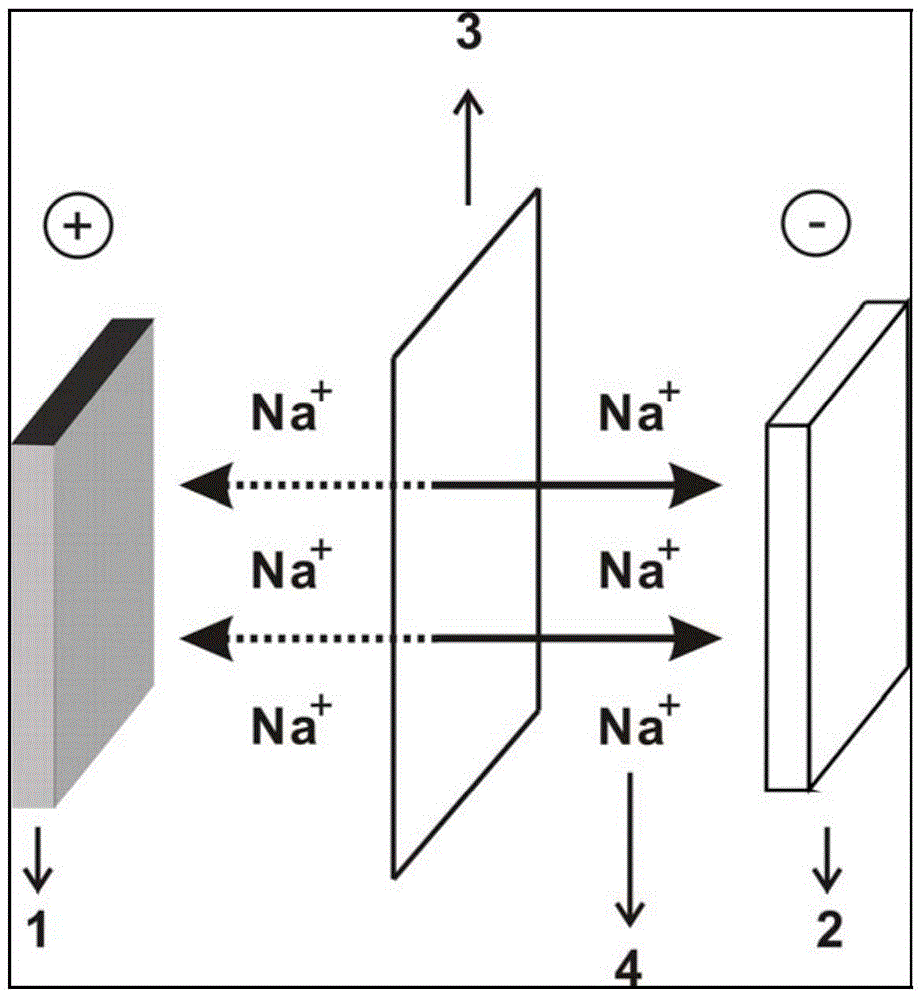

[0044] The fluorinated carbon electrode prepared in Example 1 is used as the positive pole, the sodium metal is the negative pole, the PP / PE / PP composite film Cellgard 2400 and the glass fiber are the diaphragm, and 1mol / L NaClO 4 The mixed solution of ethylene carbonate (EC) and dimethyl carbonate (DMC) (1:1v / v) is the electrolyte, and 2% fluoroethylene carbonate (FEC) additive is added to the electrolyte, and the The box is assembled into a 2025 button battery. The structure principle of sodium battery is as follows figure 1 As shown, each mark is: 1-positive active material; 2-negative active material; 3-positive current collector; 4-negative current collector; 5-diaphragm; 6-electrolyte. The constant current electrochemical performance test was carried out on the LAND battery test system (Wuhan Landian Electronics Co., Ltd.). Discharge cut-off potential is 1.5V (vs.Na + / Na), the charging cut-off potential is 4.8V (vs.Na + / Na) controls the charging capacity.

Embodiment 3

[0046] Using fluorinated acetylene black (F / C=0.53) as the positive electrode active material, referring to Example 1, PVDF was used as the binder, and NMP was used as the solvent to prepare the positive electrode for sodium batteries. Referring to Example 2, the sodium battery preparation and electrochemical performance test were carried out. Test results such as Figure 9 and 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com