Silicon oxide composite negative pole material for lithium ion secondary battery and preparation method thereof

A technology of silicon oxide and negative electrode materials, applied in the direction of battery electrodes, circuits, electrical components, etc., to reduce the hardness of materials, prevent material adhesion, and improve grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The silicon oxide composite negative electrode material of a kind of lithium ion secondary battery of the present invention can be prepared by following method:

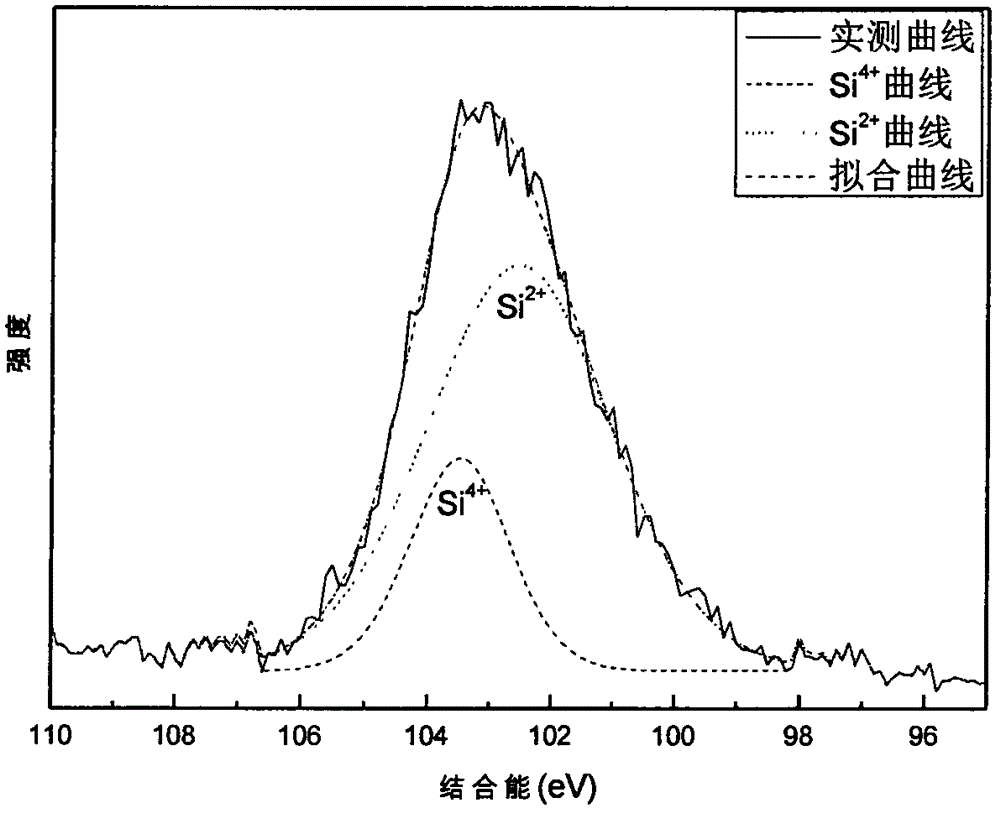

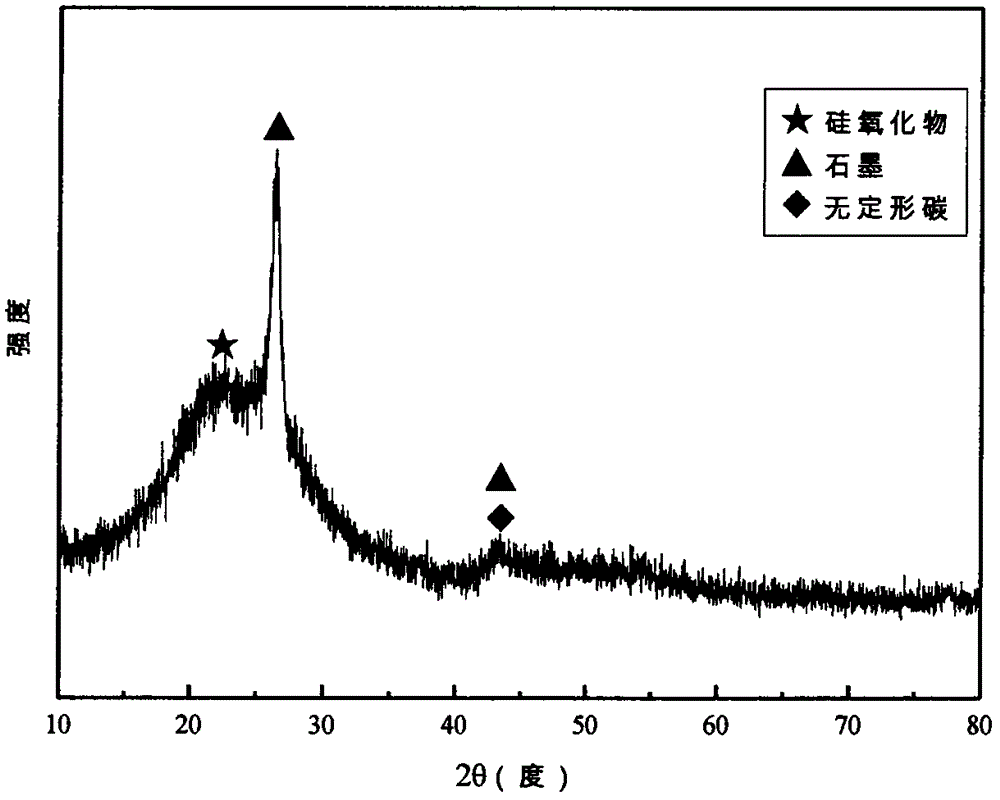

[0028] 1) Mix silica powder, magnesium powder and NaCl powder with a mass ratio of 1:0.4:10 by ball milling. The ball milling conditions are as follows: the rotation speed is 400rpm, the ball milling time is 5h, and the ball-to-material ratio is 10:1; Argon atmosphere protection Carry out magnesia thermal reduction reaction at 500°C for 4 hours, and the heating rate is 5°C / min. After cooling down to room temperature, use an excess of 0.5mol / L HCl to stand for corrosion, filter and wash, and vacuum dry to obtain silicon oxide.

[0029] 2) Mix the silicon oxide and natural graphite prepared above in a mass ratio of 10:2.5 in a planetary ball mill under the protection of an argon atmosphere. The ball milling conditions are: the rotating speed is 400rpm, the ball milling time is 20h, and the ball-to-material ratio...

Embodiment 2

[0037] 1) SiO2 powder, magnesium powder and MgCl with a mass ratio of 1:0.37:8 2 The powder is mixed by ball milling. The ball milling conditions are as follows: the rotation speed is 500rpm, the ball milling time is 1h, and the ball-to-material ratio is 5:1; the magnesia thermal reduction reaction is carried out under the protection of argon atmosphere, and the temperature is kept at 600°C for 2h, and the heating rate is 20°C / min. , after cooling down to normal temperature, use excess 0.5mol / L HCl to statically etch, filter and wash with suction, and dry in vacuum to obtain silicon oxide.

[0038] 2) Mix the silicon oxide and natural graphite prepared above in a mass ratio of 10:1 in a planetary ball mill under the protection of an argon atmosphere. The ball milling conditions are as follows: the rotating speed is 500rpm, the ball milling time is 1h, and the ball-to-material ratio is 10 : 1, a mixture was obtained. Then, under the protection of an argon atmosphere, the above...

Embodiment 3

[0043] 1) SiO2 powder, magnesium powder and CaCl with a mass ratio of 1:0.32:1 2 The powders are mixed by ball milling, the ball milling conditions are as follows: the rotation speed is 300rpm, the ball milling time is 30h, and the ball-to-material ratio is 20:1; the magnesia thermal reduction reaction is carried out under the protection of argon atmosphere, the temperature is kept at 400°C for 5h, and the heating rate is 5°C / min , after cooling down to normal temperature, use excess 0.5mol / L HCl to statically etch, filter and wash with suction, and dry in vacuum to obtain silicon oxide.

[0044] 2) Mix the silicon oxide and mesophase graphite prepared above in a mass ratio of 10:4 in a planetary ball mill under the protection of an argon atmosphere. The ball milling conditions are: the rotating speed is 300rpm, the ball milling time is 30h, and the ball-to-material ratio is 20:1, a primary mixture was obtained. Then, under the protection of an argon atmosphere, the primary m...

PUM

| Property | Measurement | Unit |

|---|---|---|

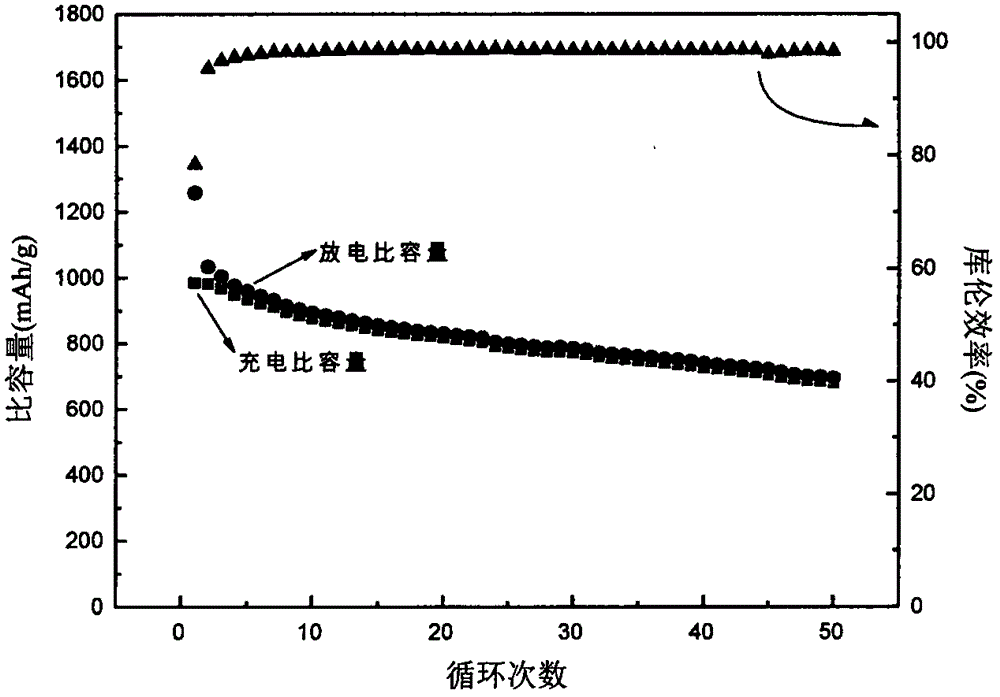

| Discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com