Processing method capable of preventing electrochemical corrosion of through-hole metals

A processing method and electrochemical technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of electrochemical corrosion of through-hole metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

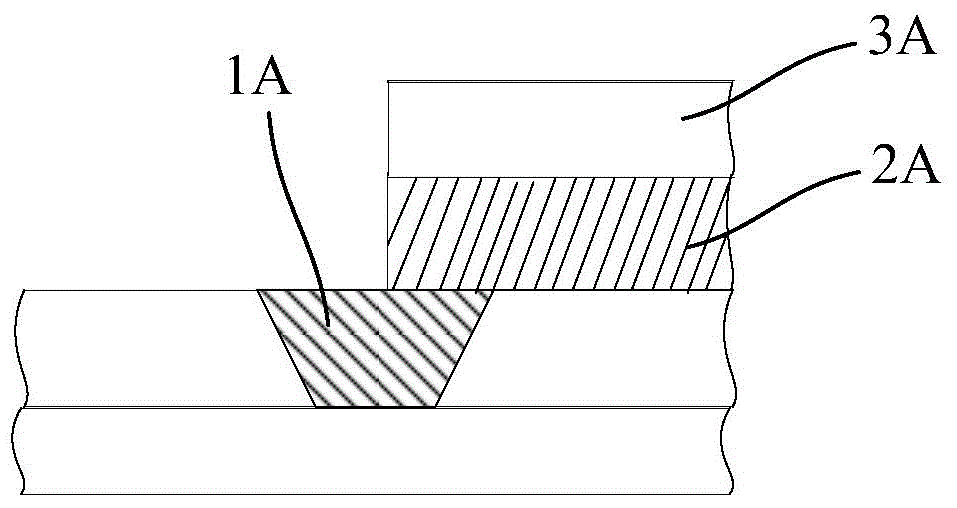

[0038] The invention provides a treatment method for avoiding electrochemical corrosion of through-hole metal, such as Figure 5 As shown, the treatment method for avoiding the electrochemical corrosion of the via metal at least includes the steps:

[0039] First, step S1 is performed to provide a metal interconnection structure, the metal interconnection structure includes a first metal layer, located in the

[0040] No.

[0041] An insulating layer with a through hole on a metal layer and a second metal layer on the insulating layer; the through hole is filled with a third metal layer to communicate with the first metal layer and the second metal layer;

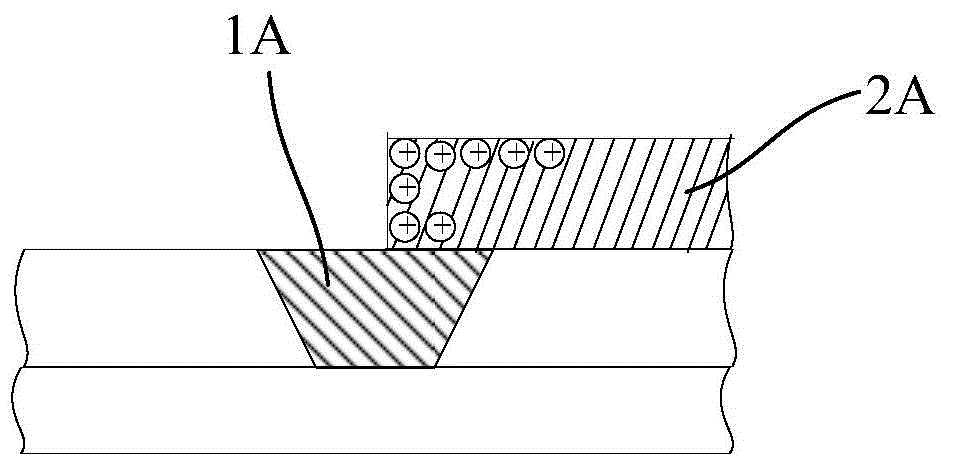

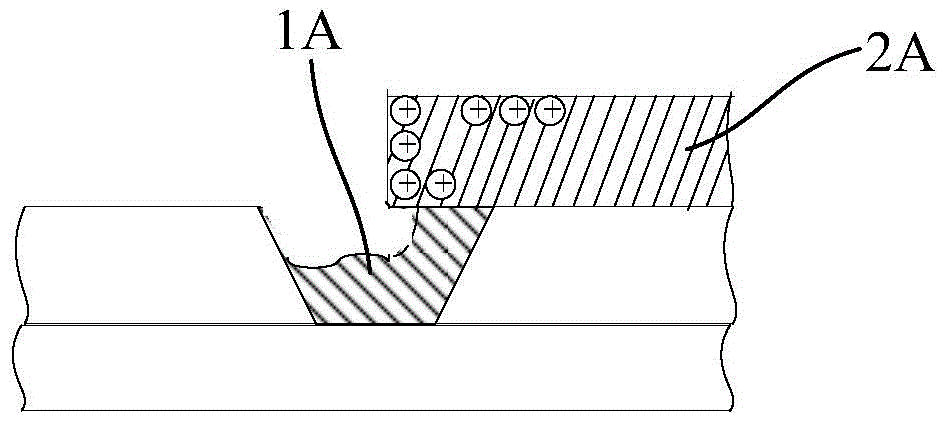

[0042] Next, step S2 is performed, placing the metal interconnection structure in the reaction chamber, and injecting N 2 and H 2 O mixed gas, plasma the N 2 and H 2 The mixed gas of O makes H 2 O is dissociated to form hydrogen atoms, and the hydrogen atoms capture the positive charges in the second metal layer to pr...

Embodiment 2

[0053] In this embodiment, the line width of the second metal layer 2 is 0.14-0.20 μm.

[0054] The treatment process of the present invention for avoiding the electrochemical corrosion of through-hole metal is completed in the reaction chamber of the plasma etching machine, the wafer is placed on the carrier of the reaction chamber, and the internal pressure of the reaction chamber is reduced by the vacuum system, so that The above pressure is set to 1.1 torr, after the vacuum is established, the reaction chamber is filled with N 2 and H 2 Mixed gas of O, N 2 and H 2 The mixed gas of O surrounds the metal interconnection structure, and then the power is turned on to create a radio frequency electric field between the parallel plate electrodes in the reaction chamber. The radio frequency power is set to 900 watts, and the mixed gas is excited into a plasma state by the radio frequency electric field.

[0055] In this example, the N in the mixed gas 2 The flow rate of the g...

Embodiment 3

[0058] In this embodiment, the line width of the second metal layer 2 is 0.20-0.30 μm.

[0059] The treatment process of the present invention for avoiding the electrochemical corrosion of through-hole metal is completed in the reaction chamber of the plasma etching machine, the wafer is placed on the carrier of the reaction chamber, and the internal pressure of the reaction chamber is reduced by the vacuum system, so that The above pressure is set to 1.1 torr, after the vacuum is established, the reaction chamber is filled with N 2 and H 2 Mixed gas of O, N 2 and H 2 The mixed gas of O surrounds the metal interconnection structure, and then the power is turned on to create a radio frequency electric field between the parallel plate electrodes in the reaction chamber. The radio frequency power is set to 900 watts, and the mixed gas is excited into a plasma state by the radio frequency electric field.

[0060] In this example, the N in the mixed gas 2 The flow rate of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com