Adsorption carrier and adsorption method thereof

An adsorption-type, stage-based technology, applied in the direction of worktables, optics, instruments, etc., can solve problems such as substrate cracking, unstable stage, equipment damage, etc., to achieve the effect of ensuring flatness, avoiding adverse effects, and ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

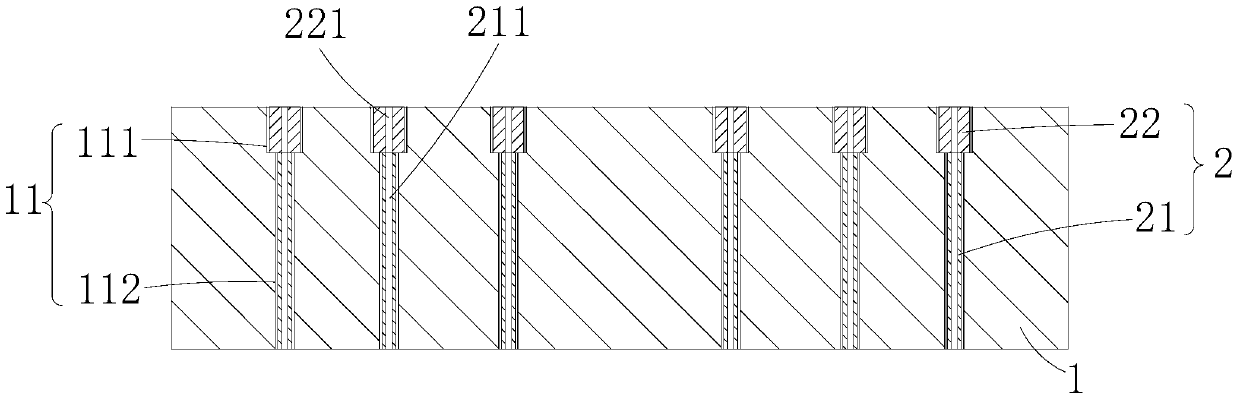

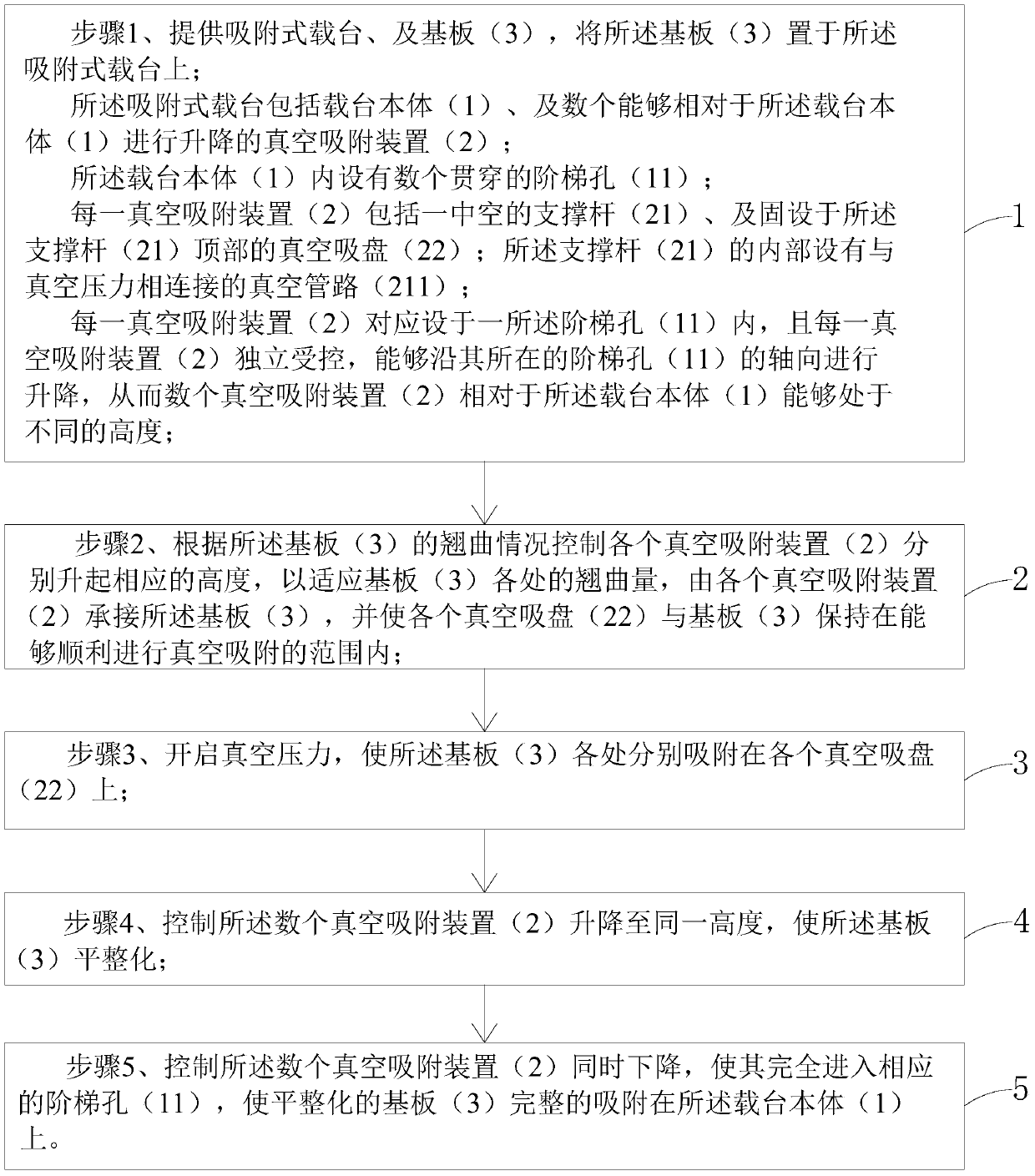

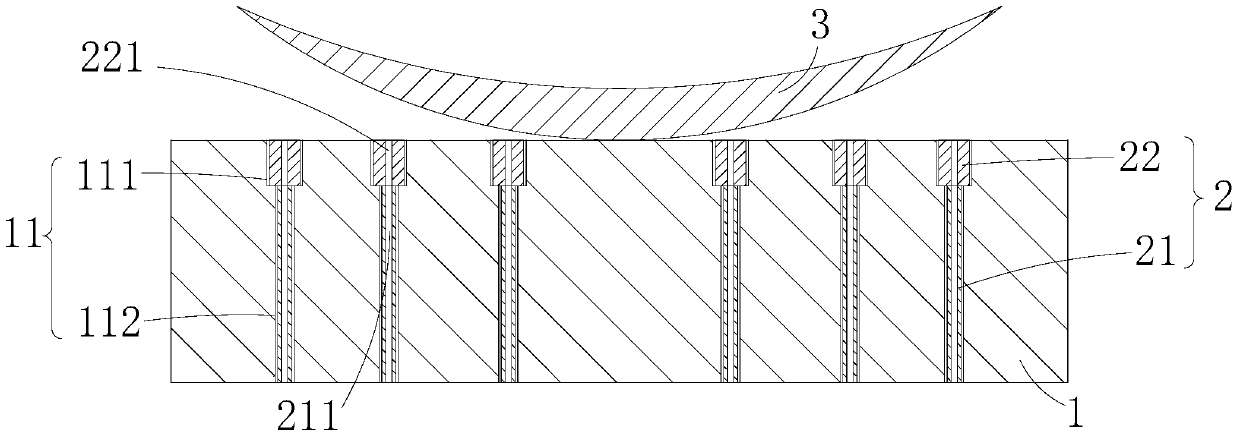

[0042] see figure 1 , combined with Figure 3 to Figure 6 , the present invention firstly provides an adsorption carrier. The suction stage includes a stage body 1 and several vacuum suction devices 2 capable of lifting relative to the stage body 1 .

[0043] The stage body 1 is used to carry the substrate 3 , and several stepped holes 11 are provided in the stage body 1 .

[0044] Each vacuum adsorption device 2 is correspondingly arranged in one of the stepped holes 11, and each vacuum adsorption device 2 is independently controlled, and can be lifted and lowered along the axial direction of the stepped hole 11 where it is located, so that several vacuum adsorption devices 2 are relatively The carrier body 1 can be at different heights. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com