Runner assembly and engine suspension comprising runner assembly

A runner assembly, runner technology, applied in mechanical equipment, shock absorber-spring combination, spring, etc., can solve the problems of large output torque of the powertrain, attenuated powertrain transmission, etc., to improve comfort, limit Position and flow channel plate structure optimization, the effect of optimizing vibration isolation and limit function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

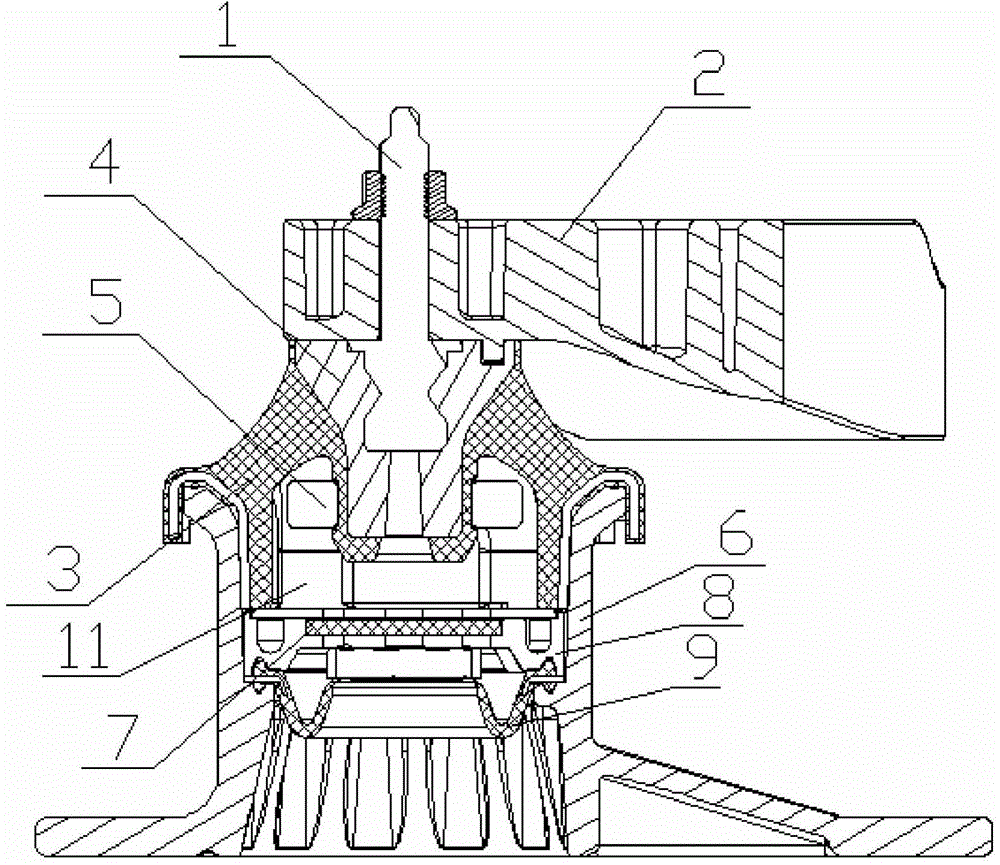

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

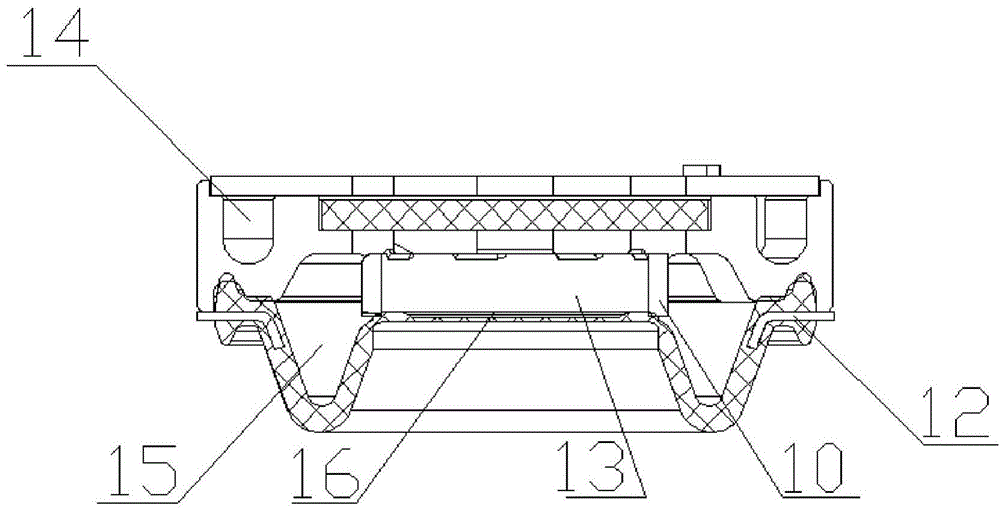

[0024] Such as figure 1 A flow channel assembly shown includes a flow channel plate 8 and a cup 9, the flow channel plate 8 is connected to the cup 9; the flow channel plate 8 is provided with a first flow channel 14 and a third flow channel 16, and the flow channel A second flow channel 15 is formed between the plate 8 and the cup 9; wherein:

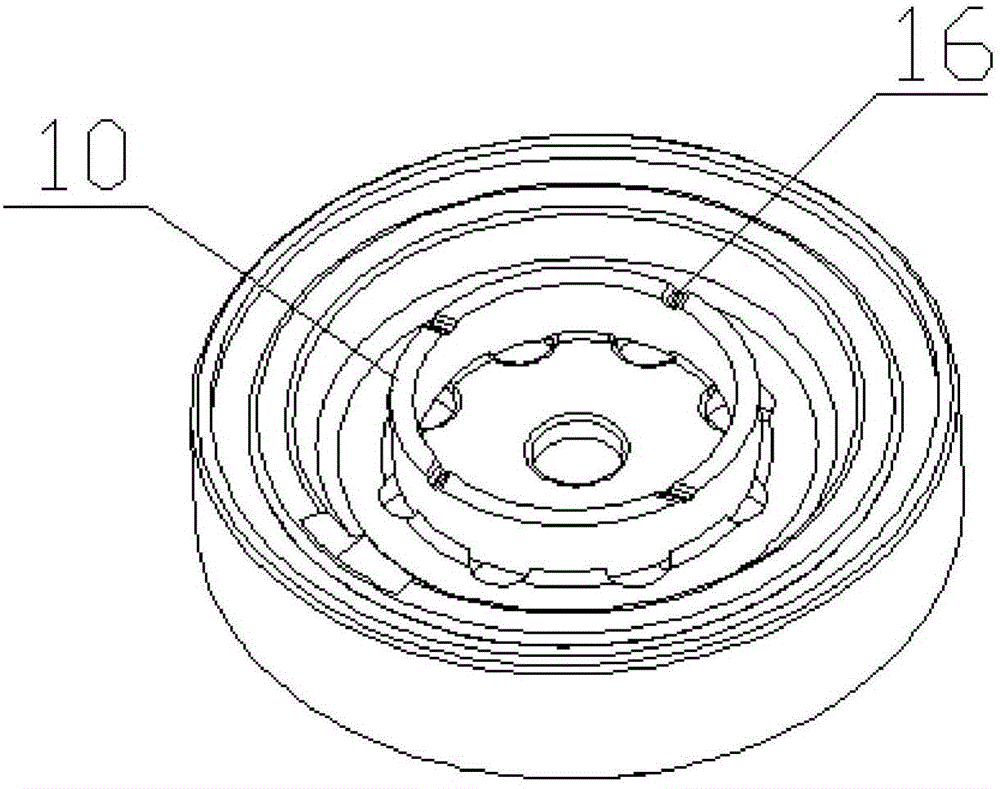

[0025] The flow channel plate 8 includes a body, a ring 10 and a joint surface, the body is provided with a decoupling film 7, the ring 10 is arranged inside the end face of the body, and the joint surface is placed between the rings 10; the first flow channel 14 is arranged on the body In the circumferential direction, the third flow channel 16 is a plurality of (4 through holes in this embodiment) through holes distributed on the joint surface (such as image 3 shown).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com