Construction method for pre-positioning water stop belt of setting arc-shaped die of quadratic lining concrete end head

A secondary lining and construction method technology, which is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems of high processing costs, hidden dangers of water seepage, rework of waterstops, etc., and achieves easy processing, small investment, and easy construction The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

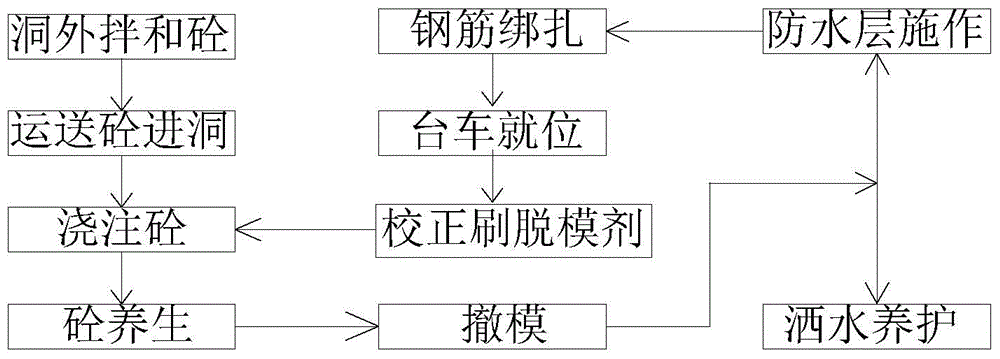

[0030] As shown in the figure, the construction method of the secondary lining concrete end shaping arc mold returning fixed waterstop provided by the present invention includes the secondary lining trolley and the second lining end shaping arc mold, including the following steps:

[0031] S1: welding a steel plate at the end of the secondary lining trolley, the arc of the steel plate matches the arc of the end of the secondary lining trolley;

[0032] S2: U-shaped steel hoop spot-welded at the end of the steel plate, one end of the buried rubber waterstop is installed in the U-shaped steel hoop, and the other end is pressed against the steel plate so that it is pre-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com