Method for constructing surface of fabric with ultraviolet protection and wash-resistant special wetting functions

A functional fabric, water-resistant technology, applied in plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of complex operation process, uncontrollable film layer morphology, poor stability, etc., to achieve simple preparation process, durable super-hydrophobicity Good performance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, the surface of a special wettable functional fabric with UV protection and water resistance is prepared according to the following steps:

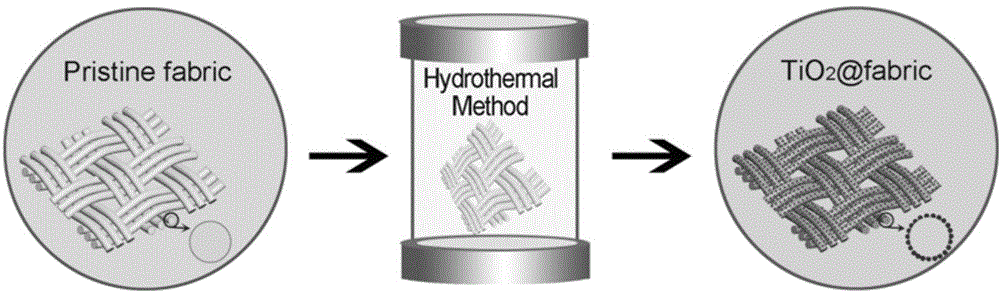

[0054] Step 1, one-step hydrothermal method to prepare nano-TiO 2 Cotton cloth on the surface of the film layer

[0055] Cut 5 pieces of cotton cloth according to the size of 3×3cm, put them in a beaker, and pass through deionized water and absolute ethanol for 5 minutes. Weigh 0.5mmol titanium potassium oxalate with an electronic balance, dissolve it in a mixed solution of 15ml deionized water and 20ml diethylene glycol, stir evenly under the action of a magnetic rotor, then add clean cotton cloth, and place it in a hydrothermal reaction kettle Pressurize and tighten, and finally put the hydrothermal reactor into an oven at 100°C to react for 0.5h. After the reaction, thoroughly clean the excess reactant on the surface of the cotton fabric with deionized water.

[0056] Step 2. Fluorosilane modification to pre...

Embodiment 2

[0060] In this embodiment, the surface of a special wettable functional fabric with UV protection and water resistance is prepared according to the following steps:

[0061] Step 1, one-step hydrothermal method to prepare nano-TiO 2 Cotton cloth on the surface of the film layer

[0062] Cut 5 pieces of cotton cloth according to the size of 3×3cm, put them in a beaker, and pass through deionized water and absolute ethanol for 5 minutes. Weigh 2mmol potassium titanium oxalate with an electronic balance, dissolve it in a mixed solution of 15ml deionized water and 20ml diethylene glycol, stir evenly under the action of a magnetic rotor, then add clean cotton cloth, and place it in a hydrothermal reaction kettle And pressurize and tighten, and finally put the hydrothermal reaction kettle into an oven at 150°C to react for 10 hours. After the reaction is completed, thoroughly clean the excess reactant on the surface of the cotton fabric with deionized water.

[0063] Step 2. Fluor...

Embodiment 3

[0067] In this embodiment, the surface of a special wettable functional fabric with UV protection and water resistance is prepared according to the following steps:

[0068] Step 1, one-step hydrothermal method to prepare nano-TiO 2 Cotton cloth on the surface of the film layer

[0069] Cut 5 pieces of cotton cloth according to the size of 3×3cm, put them in a beaker, and pass through deionized water and absolute ethanol for 5 minutes. Weigh 3mmol potassium titanium oxalate with an electronic balance, dissolve it in a mixed solution of 20ml deionized water and 15ml diethylene glycol, stir evenly under the action of a magnetic rotor, then add clean cotton cloth, and place it in a hydrothermal reaction kettle And pressurize and tighten, and finally put the hydrothermal reaction kettle into the oven at 180°C to react for 20 hours. After the reaction is completed, thoroughly clean the excess reactants on the surface of the cotton fabric with deionized water.

[0070] Step 2. Flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com