Device and method for treating antimony-arsenic materials

A material and volatile matter technology, applied in the field of antimony and arsenic material processing, can solve the problem of difficult removal of harmful impurity arsenic, and achieve the effect of improving corporate profits, short process flow and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

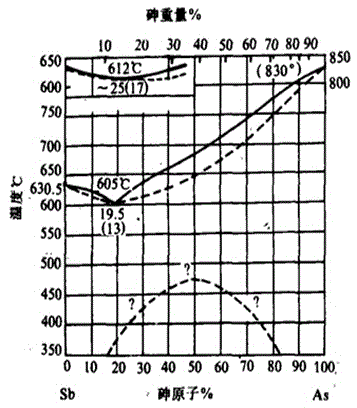

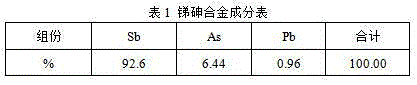

[0039] Embodiment 1. The raw material used is a kind of antimony-arsenic alloy, its main chemical composition is antimony and arsenic, there is a small amount of lead, composition is shown in Table 1, main technical parameters: distillation temperature 950 ℃, holding time 30min, vacuum degree 500Pa.

[0040]

[0041] The specific implementation steps are as follows:

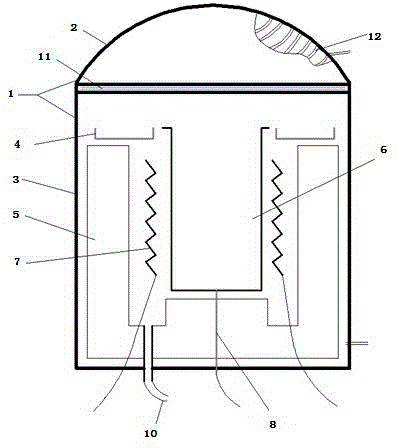

[0042](1) Feeding: Take 300g of the above-mentioned antimony-arsenic alloy material and add it to the graphite crucible in the furnace, cover the furnace cover, and seal the furnace body;

[0043] (2) Vacuuming: Turn on the vacuum pump to evacuate, heat up when the vacuum degree in the furnace reaches 500 Pa, and continue to evacuate;

[0044] (3) Heating up: Turn on the water cooling system, raise the temperature of the furnace body while the vacuum pump is running, so that the temperature in the furnace reaches 950°C, and continue to vacuumize;

[0045] (4) Heat preservation: After the temperature in the fu...

Embodiment 2

[0050] Embodiment 2. The raw materials used are the same as in Example 1, and the main technical parameters are: distillation temperature 900°C, holding time 90min, vacuum degree 300Pa.

[0051] The specific implementation steps are as follows:

[0052] (1) Feeding: Take 300g of the above-mentioned antimony-arsenic alloy material and add it to the graphite crucible in the furnace, cover the furnace cover, and seal the furnace body;

[0053] (2) Vacuuming: Turn on the vacuum pump to evacuate, and when the vacuum in the furnace reaches 300Pa, turn on the heating system and continue to evacuate;

[0054] (3) Heating up: Turn on the water cooling system, raise the temperature of the furnace body while the vacuum pump is running, so that the temperature in the furnace reaches 900°C, and continue to vacuumize;

[0055] (4) Heat preservation: After the temperature in the furnace reaches 900°C, adjust the heating power, keep heat for 60 minutes, and continue to vacuumize;

[0056] ...

Embodiment 3

[0060] Embodiment 3. raw materials used are the same as example one, see table 1. Main technical parameters: Distillation temperature 800°C, holding time 90min, vacuum degree 300Pa.

[0061] The specific implementation steps are as follows:

[0062] (1) Feeding: Take 300g of the above-mentioned antimony-arsenic alloy material and add it to the graphite crucible in the furnace, cover the furnace cover, and seal the furnace body;

[0063] (2) Vacuuming: Turn on the vacuum pump to evacuate, and when the vacuum in the furnace reaches 300 Pa, turn on the heating system and continue to evacuate;

[0064] (3) Heating up: Turn on the water cooling system, raise the temperature of the furnace body while the vacuum pump is running, so that the temperature in the furnace reaches 800°C, and continue to vacuumize;

[0065] (4) Heat preservation: After the temperature in the furnace reaches 800°C, adjust the heating power, keep heat for 90 minutes, and continue to vacuumize;

[0066] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com