Thermo-oxidative-aging-resistant polypropylene composite and preparation method thereof

A polypropylene and thermo-oxidative resistance technology is applied in the field of thermo-oxidative aging-resistant polypropylene composites and their preparation, and can solve the problems of poor thermo-oxidative aging resistance, large steric hindrance of phenolic hydroxyl groups, and decreased thermo-oxidative aging performance, etc. Achieving good thermal oxidation resistance, low cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

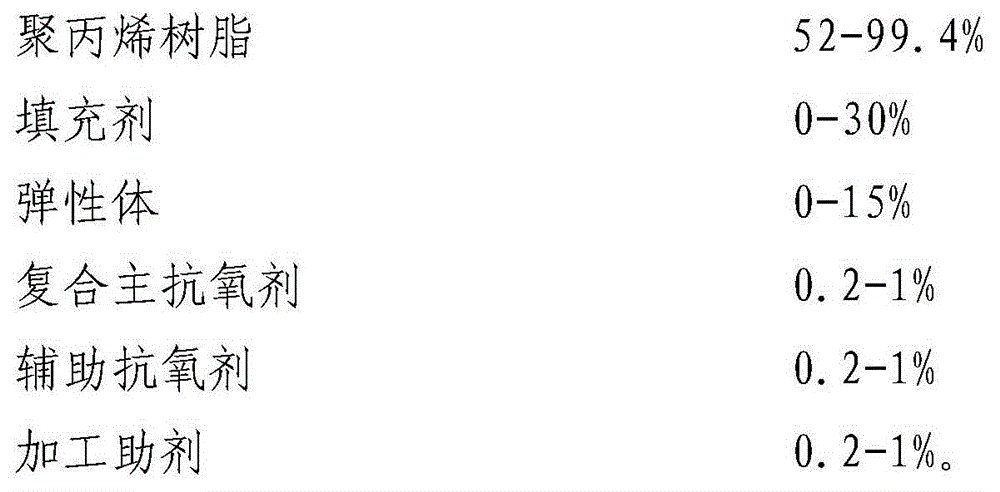

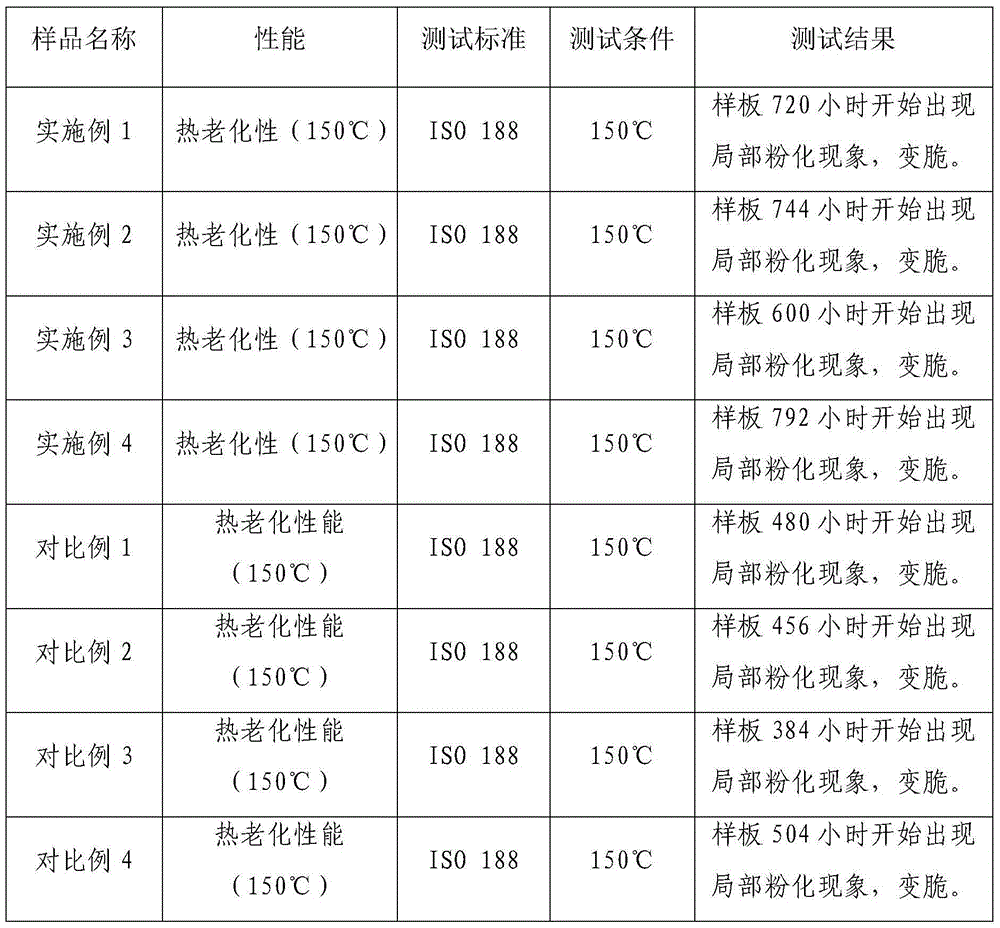

[0026] 99.2 kg of polypropylene PP (S700), 0.2 kg of hindered phenol heat stabilizer 1010, 0.1 kg of semi-hindered phenol antioxidant AO-80, 0.3 kg of phosphite heat stabilizer 168, and 0.2 kg of processing aid EBS in the long Melt, mix and disperse in a twin-screw extruder with a diameter ratio of 40:1, extrude and granulate at 200°C, and finally obtain a polypropylene compound. Its performance test parameters are shown in Table 1.

Embodiment 2

[0028] 83.9 kg of polypropylene PP (Z30S), 10 kg of talcum powder (3000 mesh), 5 kg of ethylene octene copolymer POE DF610, 0.25 kg of hindered phenol antioxidant 3114, 0.15 kg of semi-hindered phenol antioxidant 1790, 0.4 Kg of phosphite heat stabilizer PEP-36 and 0.3 kg of processing aid calcium stearate were melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, extruded and granulated at 200°C, and finally obtained poly Propylene compound. Its performance test parameters are shown in Table 1.

Embodiment 3

[0030] 73.5 kg of polypropylene PP (BX3800), 15 kg of talcum powder (3000 mesh), 10 kg of ethylene octene copolymer POE 8137, 0.3 kg of hindered phenol heat stabilizer 1076, 0.2 kg of semi-hindered phenol antioxidant 245, 0.5 kg Thioester heat stabilizer 412S and 0.5 kg of processing aid zinc stearate were melt mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, extruded and granulated at 200°C, and finally obtained a polypropylene compound . Its performance test parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com