Special anti-ageing dimming green master batch for ginger greenhouse film and preparation method of special anti-ageing dimming green master batch

An anti-aging and shed film technology, which is applied in the field of materials, can solve the problems that the increase or decrease of the added amount cannot meet the transmitted light quality of ginger, cannot maintain the growth light environment of ginger, and the strength of the shed film is reduced, so as to achieve good heat preservation, low cost, Effect of Green Light Addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

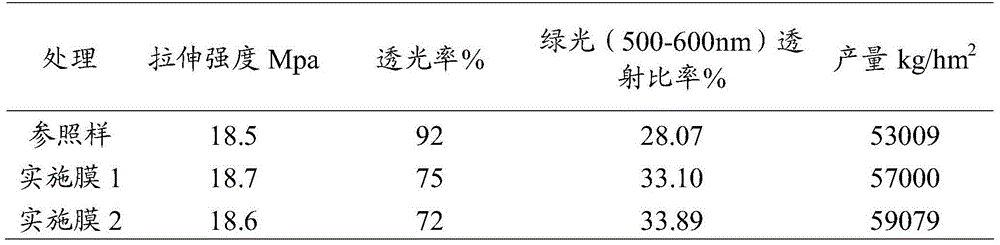

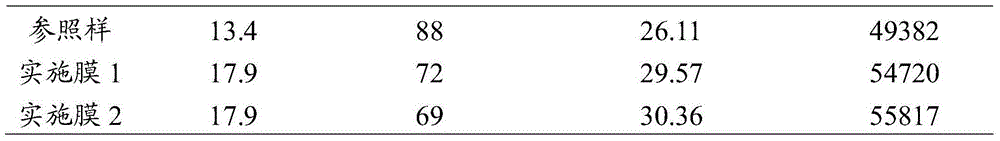

Examples

Embodiment 1

[0039] A special anti-aging and dimming green masterbatch for ginger shed film, the composition of which is as follows:

[0040] 20kg of LLDPE powder, 2.5kg of phthalocyanine green G, 0.5kg of fast yellow G, 0.5kg of spinel multi-metal oxide composite pigment yellow, 0.1kg of rutile titanium dioxide, 0.5kg of zinc stearate, 1kg of polyethylene wax , diatomaceous earth 0.13kg, light stabilizer HS-3620.2kg, antioxidant B2150.1kg.

[0041] Its preparation method comprises the following steps:

[0042] Step 1: First, mix the antioxidant, light stabilizer and slow-release agent in proportion, place them in a grinding container, grind them with a high-speed grinder at a speed of 300-500r / min for 15 minutes, and grind them evenly to obtain mixed raw materials;

[0043] Step 2: Add the carrier resin, pigment, titanium dioxide, dispersant, and the mixed raw materials described in Step 1 into a high-speed mixer and mix for 15-30 minutes at a speed of 600 r / min, or mix in an internal mi...

Embodiment 2

[0046] A special anti-aging and dimming green masterbatch for ginger shed film. Its components are as follows: LLDPE 15kg, EVA 5kg, phthalocyanine green K8370 2.0kg, spinel multi-metal oxide composite pigment green 0.5kg, benzidine organic Yellow G 0.5kg, rutile titanium oxide composite pigment yellow 0.2kg, anatase titanium dioxide 0.2kg, EVA wax 0.5kg, zinc stearate 0.5kg, polyethylene wax 1kg, montmorillonite 0.16kg, light stabilizer 3260.3kg, antioxidant

[0047]Its preparation method comprises the following steps:

[0048] Step 1: First, mix the antioxidant, light stabilizer and slow-release agent in proportion, place them in a grinding container, grind them with a high-speed grinder at a speed of 300-500r / min for 10 minutes, and grind them evenly to obtain mixed raw materials;

[0049] Step 2: Add the carrier resin, pigment, titanium dioxide, dispersant and the mixed raw materials described in step 1 into a high-speed mixer and mix for 15-30min at a speed of 610r / min...

Embodiment 3

[0052] A special anti-aging and dimming green masterbatch for ginger shed film, its components are as follows: EVA 20kg, phthalocyanine green K8370 2.0kg, spinel type multi-metal oxide composite pigment green 0.5kg, benzidine organic yellow G 0.4 kg, Fast Yellow G 0.3kg, Rutile Titanium Dioxide 0.25kg, EVA Wax 0.5kg, Polyethylene Wax 1kg, Vermiculite 0.16kg, Light Stabilizer Antioxidants

[0053] Its preparation method comprises the following steps:

[0054] Step 1: First, mix the antioxidant, light stabilizer and slow-release agent in proportion, place them in a grinding container, grind them with a high-speed grinder at a speed of 300-500r / min for 5 minutes, and grind them evenly to obtain mixed raw materials;

[0055] Step 2: Add the carrier resin, pigment, titanium dioxide, dispersant and the mixed raw materials described in step 1 into a high-speed mixer and mix for 15-30min at a speed of 650r / min, or mix in an internal mixer for 20-40min, The banburying temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com