A kind of synthetic method of epoxy-terminated polythioether liquid rubber

A technology based on polythioether and liquid rubber, which is applied in the field of high molecular polymer production, can solve the problem of severe reaction exotherm, and achieve the effects of uniform molecular weight distribution, moderate viscosity and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

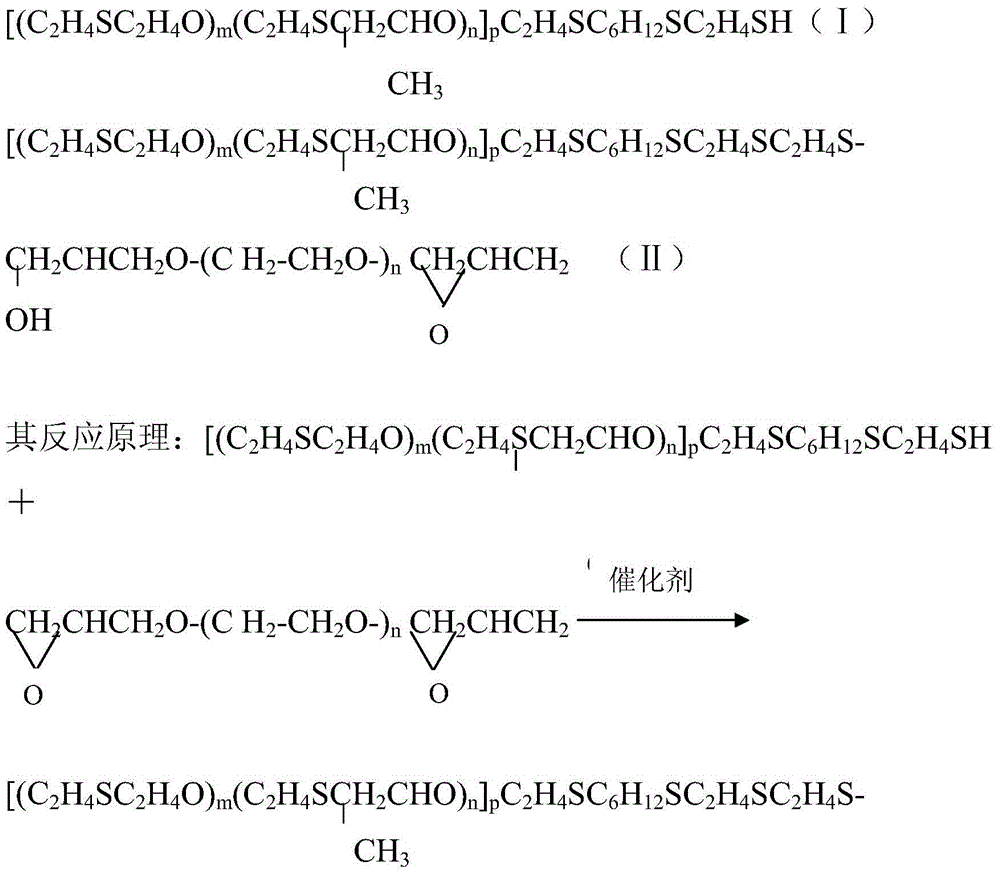

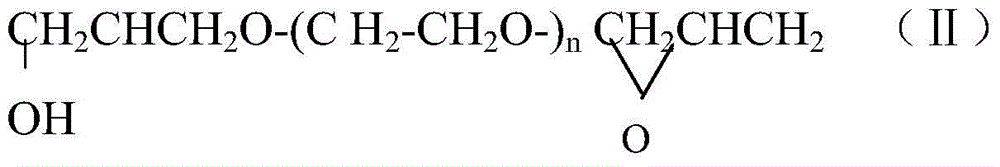

Method used

Image

Examples

Embodiment 1

[0026] In a 5L stainless steel reactor equipped with a stirrer, a thermometer, a condenser and a low molecular weight receiver, the mercapto-terminated polythioether liquid rubber I JLM-2006-4 (product of Jinxi Institute of Technology, the number-average weight is 3891, The cross-linking degree is 2.5, the viscosity is 42.3Pa s) 4kg, 1.05kg polyethylene glycol diglycidyl ether resin (DER732), 11.6g peroxide and 1.4g amine composite catalyst, and the temperature is raised to 80 °C to control the reaction temperature 80±2°C, react for 12h, continue to heat up to 140°C, at 140±2°C, control the residual pressure below 20mmHg, carry out vacuum reaction for 4h, remove unreacted small molecular substances, and obtain epoxy-terminated polythioether liquid rubber Ⅱ, epoxy value 0.07, viscosity 62.5Pa s, density 1.15g / cm 3 .

Embodiment 2

[0028] In a 5L stainless steel reactor equipped with a stirrer, a thermometer, a condenser and a low molecular weight receiver, the mercapto-terminated polythioether liquid rubber IJLM-2006-3 (product of Jinxi Institute of Technology, the number-average weight is 4217, The cross-linking degree is 2.3, the viscosity is 45.8Pa s) 4kg, 0.9kg polyethylene glycol diglycidyl ether resin (DER732), 10.3g peroxide and 1.2g amine composite catalyst, and the temperature is raised to 80 °C to control the reaction temperature 80±2°C, react for 12h, continue to heat up to 140°C, at 140±2°C, control the residual pressure below 20mmHg, carry out vacuum reaction for 4h, remove unreacted small molecular substances, and obtain epoxy-terminated polythioether liquid rubber Ⅱ, epoxy value 0.06, viscosity 65.8Pa s, density 1.15g / cm 3 .

Embodiment 3

[0030] In a 5L stainless steel reactor equipped with a stirrer, a thermometer, a condenser and a low molecular weight receiver, the mercapto-terminated polythioether liquid rubber ⅠJLM-2006-1 (product of Jinxi Institute of Technology, the number-average weight is 4358, The cross-linking degree is 2.8, the viscosity is 54.1Pa s) 4kg, 1.05kg polyethylene glycol diglycidyl ether resin (DER732), 11.6g peroxide and 1.4g amine composite catalyst, and the temperature is raised to 80 °C to control the reaction temperature 80±2°C, react for 12h, continue to heat up to 140°C, at 140±2°C, control the residual pressure below 20mmHg, carry out vacuum reaction for 4h, remove unreacted small molecular substances, and obtain epoxy-terminated polythioether liquid rubber Ⅱ, epoxy value 0.077, viscosity 70.5Pa s, density 1.17g / cm 3 .

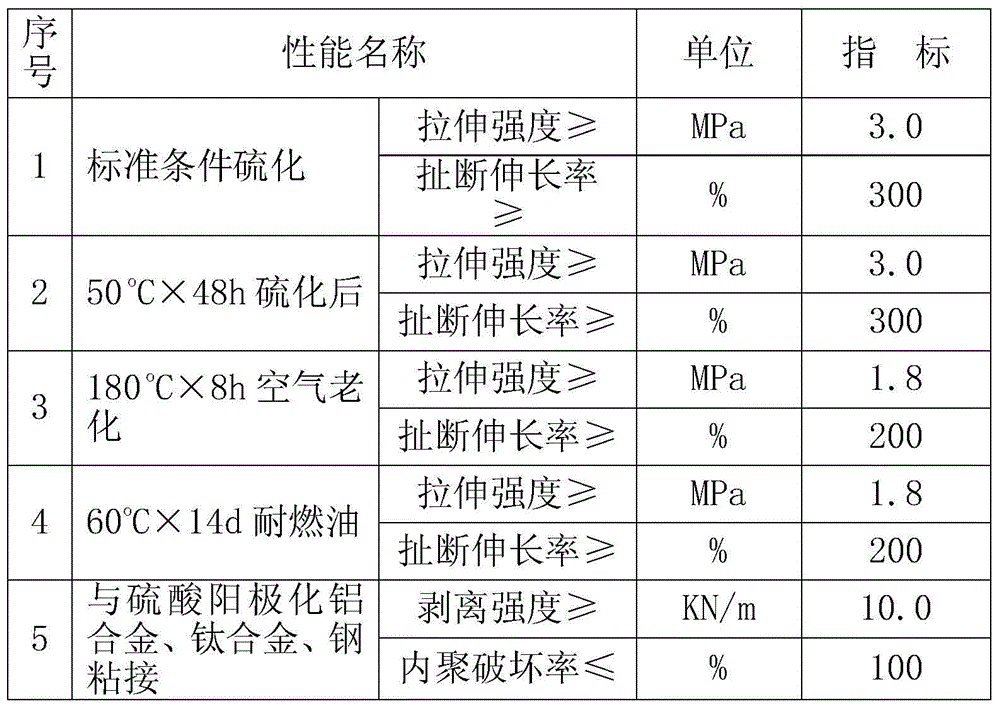

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com