Production method of ethyl acetate

A production method and technology for ethyl acetate, applied in the field of preparation and separation of ethyl acetate, can solve the problems of low conversion rate of ethanol, complicated separation process, equipment corrosion, etc., improve the conversion rate, solve the problems of complex technological process and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

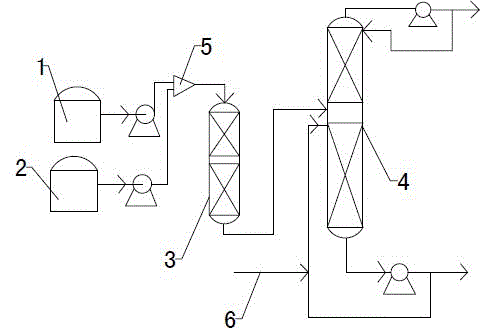

Image

Examples

Embodiment 1~4

[0027] 98% chemically pure acetic acid and absolute ethanol are metered and mixed at a molar ratio of 1:1 through a plunger pump, and then injected into a fixed-bed pre-reactor equipped with a resin catalyst, and the pre-reacted mixture enters a catalytic distillation tower, unreacted ethanol fully reacts with supplemented acetic acid. Wherein, the molar ratio of supplemented acetic acid to unreacted ethanol is 1.5:1. The loading amount of the catalyst in the fixed bed prereactor is 40ml, and the loading amount of the catalyst in the catalytic distillation tower is 100ml.

[0028] The test results under different temperature and space velocity conditions are shown in Table 1.

[0029] Table 1 Reaction results under different temperature and space velocity conditions

[0030]

Embodiment 5~6

[0032] Acetic acid with a mass fraction of 90% and ethanol with a mass fraction of 90% are metered and mixed at a molar ratio of 1:1 through a plunger pump, and then injected into a fixed-bed pre-reactor equipped with a resin catalyst, and the pre-reacted mixture enters a catalytic distillation tower , the unreacted ethanol fully reacts with the supplemented acetic acid. Wherein, the molar ratio of supplemented acetic acid to unreacted ethanol is 2:1. The loading amount of the catalyst in the fixed bed prereactor is 40ml, and the loading amount of the catalyst in the catalytic distillation tower is 100ml.

[0033] The test results under different temperature and space velocity conditions are shown in Table 2.

[0034] Table 2 Reaction results under different temperature and space velocity conditions

[0035]

Embodiment 7~8

[0037] Acetic acid with a mass fraction of 85% and ethanol with a mass fraction of 85% are metered and mixed at a molar ratio of 1:1 through a plunger pump, and then injected into a fixed-bed pre-reactor equipped with a resin catalyst, and the pre-reacted mixture enters a catalytic distillation tower , the unreacted ethanol fully reacts with the supplemented acetic acid. Wherein, the molar ratio of supplemented acetic acid to unreacted ethanol is 2:1. The loading amount of the catalyst in the fixed bed prereactor is 40ml, and the loading amount of the catalyst in the catalytic distillation tower is 100ml.

[0038] The test results under different temperature and space velocity conditions are shown in Table 3.

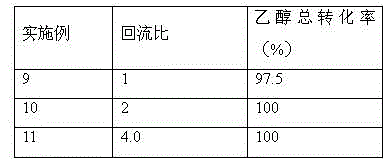

[0039] Table 3 Reaction results under different temperature and space velocity conditions

[0040]

[0041] It can be seen that the ethanol in Example 1, Example 3, Example 5 and Example 7 has been completely converted, and the product purity of ethyl acetate reach...

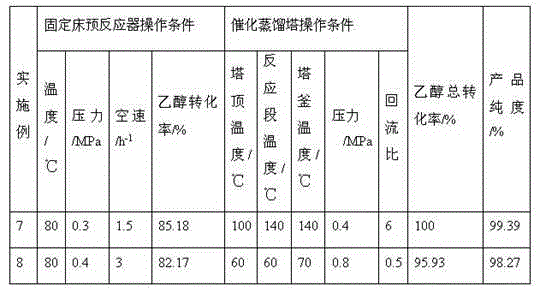

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com