An anti-seismic crack-proof prefabricated concrete square pile

A prefabricated concrete and concrete technology, applied in the field of building materials, can solve the problems of low durability, high foundation cost, broken piles, etc., and achieve the effects of improving anti-seismic cracking performance, ensuring safety, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An anti-seismic crack-proof prefabricated concrete square pile. The weights of raw materials in the concrete of each cubic meter square pile are: 125 parts of stones, 350 parts of yellow sand, 98 parts of water reducing agent, 210 parts of cement, 34 parts of anti-seismic mixture and 20 parts of anti-split polymeric fiber mixture.

[0020] Specifically, the weight components of each raw material when preparing the anti-seismic mixture are: 16 parts of industrial aluminum sulfate, 1 part of sodium lauryl sulfate, 18 parts of silica fume, 20 parts of anhydrite, 14 parts of sulfur aluminum Salt clinker.

[0021] Specifically, the water reducing agent is barium hydroxide.

[0022] On this basis, the choice of water reducer is not limited to this, you can also choose any one or several of sodium citrate, boric acid, sodium hexametaphosphate, sodium benzoate, sodium dodecylbenzenesulfonate mixture.

[0023] Specifically, the anti-split polymer fiber mixture is used to prep...

Embodiment 2

[0026] On the basis of Example 1, an anti-seismic and anti-cracking prefabricated concrete square pile, the feeding weight of each raw material in the concrete of each cubic meter of square pile is changed as follows: 135 parts of stones, 480 parts of yellow sand, 102 parts of water reducing agent, cement 250 parts, 45 parts anti-seismic compound and 80 parts anti-split polymeric fiber compound.

[0027] Specifically, the weight components of each raw material when changing the anti-seismic mixture preparation are: 26 parts of industrial aluminum sulfate, 5 parts of sodium lauryl sulfate, 35 parts of silica fume, 38 parts of anhydrite, 25 parts of sulfur Aluminate clinker.

[0028] Specifically, the raw material components prepared by changing the anti-cracking polymer fiber mixture and its parts by weight are 80 parts of polyacryl alcohol fiber and 30 parts of polybutene fiber.

Embodiment 3

[0030] On the basis of Example 1 or 2, the feeding weights of each raw material in the concrete of each cubic meter of square pile are changed as follows: 130 parts of gravel, 380 parts of yellow sand, 100 parts of water reducing agent, 235 parts of cement, and 41 parts of anti-seismic mixture and 56 parts of anti-split polymeric fiber mixture.

[0031] Specifically, the weight components of each raw material when changing the anti-seismic mixture preparation are 23 parts of industrial aluminum sulfate, 3 parts of sodium lauryl sulfate, 24 parts of silica fume, 27 parts of anhydrite, and 19 parts of sulfur aluminum Salt clinker.

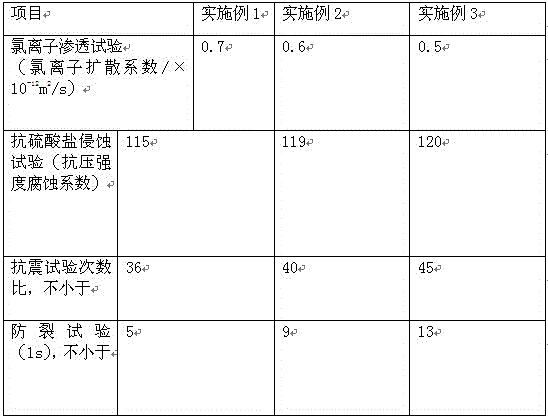

[0032] The performance index of the anti-seismic crack-proof hollow square pile that uses the concrete of embodiment 1,2,3 to make is as follows:

[0033]

[0034] It can be seen from the above table that the anti-seismic and anti-crack performance of the hollow square pile made of the concrete of this embodiment has also been significantly impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com