Oil sludge demulsifier and oil sludge resourceful treatment process

A technology of demulsifier and oil sludge, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., which can solve the problems of large environmental impact, complicated preparation of demulsifier, and unfavorable practical application, etc. problem, to achieve the effect of good demulsification effect, easy industrial application, and little impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

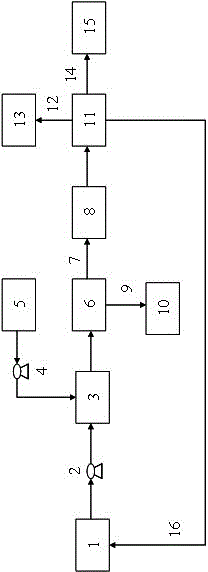

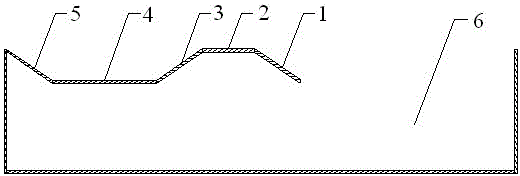

Method used

Image

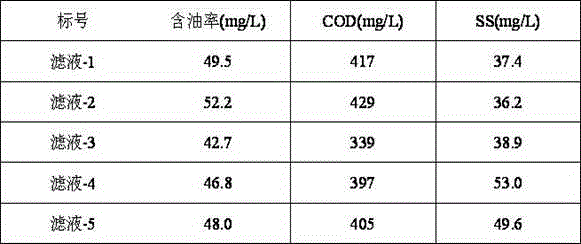

Examples

Embodiment 1

[0034] Sodium fatty acid methyl ester sulfonate (R=C 16 ) 28 parts, alkyl polyglucoside (R=C 10 , n=3) 3 parts, 1 part of sodium citrate, and 68 parts of water were mixed in a reaction kettle at a temperature of 55°C for 40 minutes, and citric acid and sodium bicarbonate were added to adjust the pH value to 5-7 to obtain a sludge demulsifier.

Embodiment 2

[0036] Sodium fatty acid methyl ester sulfonate (R=C 16 ) 15 parts, alkyl polyglucoside (R=C 12 , n=3) 5 parts, 1 part of sodium citrate, and 79 parts of water were mixed in a reaction kettle at a temperature of 50°C for 35 minutes, and sorbic acid and sodium bicarbonate were added to adjust the pH value to 5-7 to obtain a sludge demulsifier.

Embodiment 3

[0038] Sodium fatty acid methyl ester sulfonate (R=C 14 ) 10 parts, alkyl polyglucoside (R=C 10 , n=2) 8 parts, 1 part of sodium citrate, and 81 parts of water were mixed in a reaction kettle at a temperature of 53°C for 35 minutes, and citric acid and sodium hydroxide were added to adjust the pH value to 5-7 to obtain a sludge demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com