High-speed printing head of 3D printer

A 3D printer, high-speed printing technology, applied in the direction of additive processing, etc., can solve the problems that affect the printing speed, cannot achieve accuracy, cannot be used directly, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

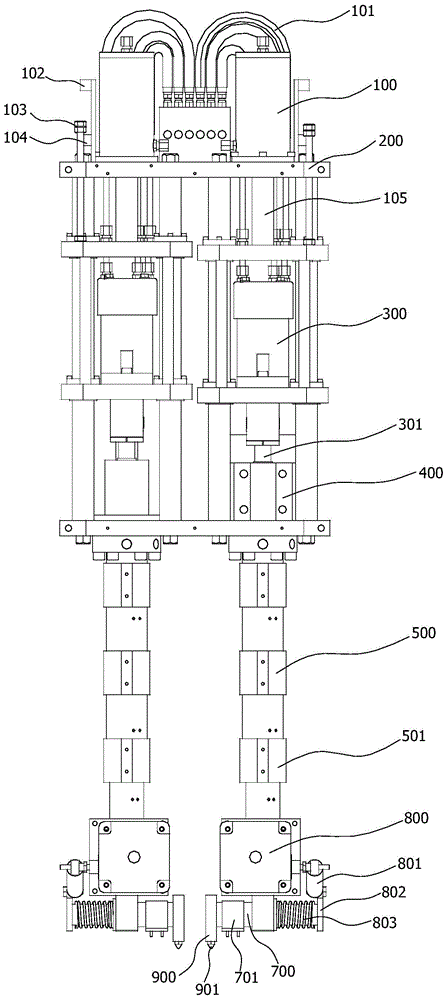

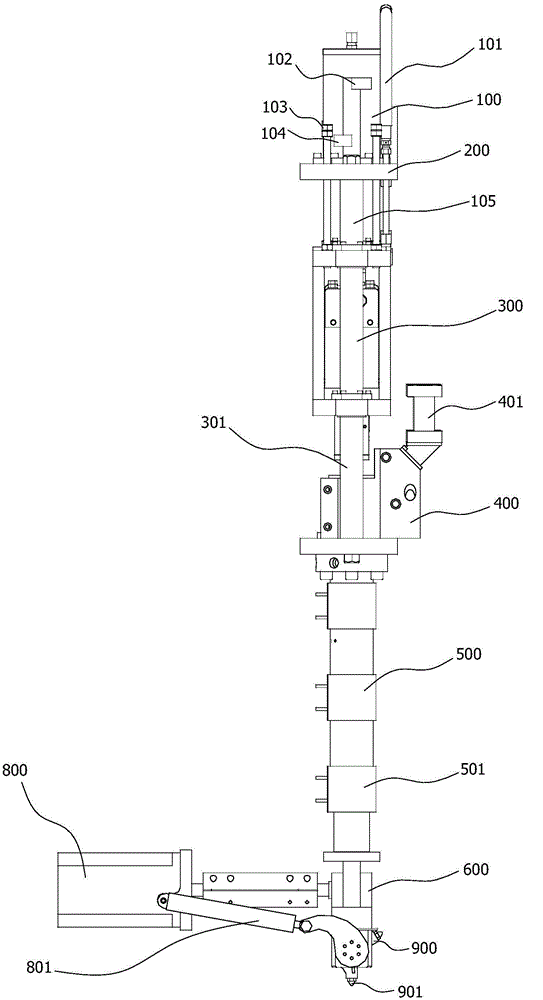

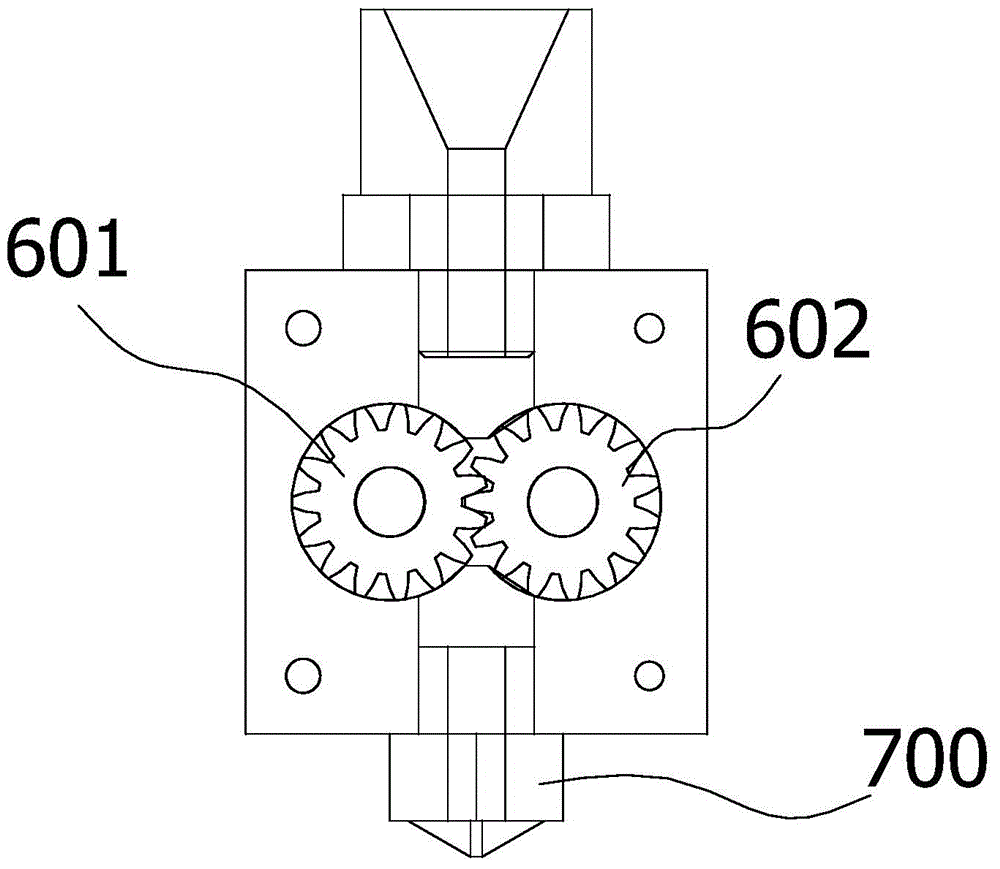

[0019] A high-speed printing head for a 3D printer, please refer to Figure 1 to Figure 3 , including a frame 200, a hydraulic cylinder 100 is fixed above the frame 200, a feeding device that can slide up and down along the frame 200 is fixed on the piston rod 105 of the hydraulic cylinder 100, and the outlet of the feeding device passes through A displacement metering pump 600 communicates with the nozzle structure, and a feed pipe 500 is longitudinally arranged on the frame 200, and the feed device includes a drive device 300 and a screw 301 driven by the drive device 300 to rotate, and the feed pipe 500 surrounds The screw is provided with a mixer 400 above it, the mixer 400 is also provided with a feed port 401, the bottom of the feed pipe 500 is set as a feed hot melt cavity 501, and the end of the screw 301 is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com