Water-based soldering flux and preparation method thereof

A flux, water-based technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low surface insulation resistivity, incomplete and uneven solder joints, flammable and explosive, etc., to achieve excellent lubricity, Good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

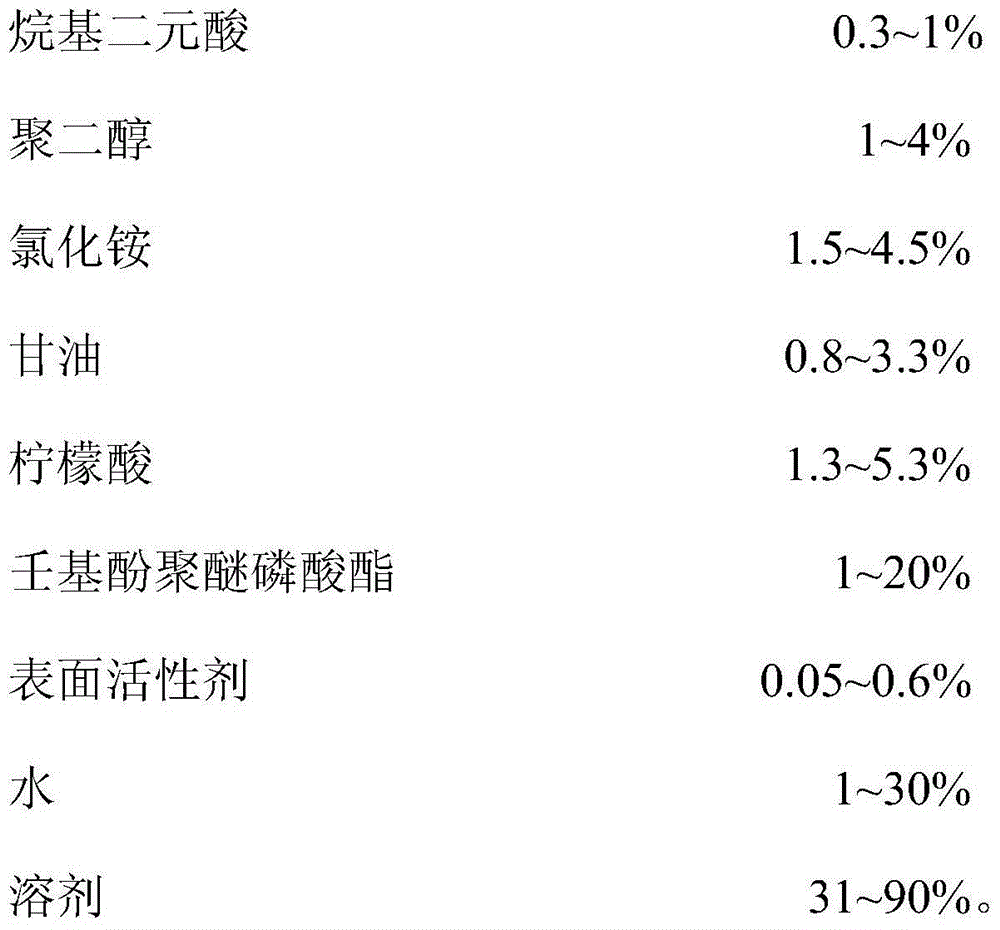

[0062] A kind of water-based soldering flux of the present invention comprises the raw material of following mass percentage:

[0063]

[0064]

[0065] A preparation method of water-based flux, comprising the following processing steps:

[0066] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0067] Among them, when weighing the solvent, it is weighed three times. For the first time, the solvent equal to the mass of nonylphenol polyether phosphate is weighed and placed in the first container. The second time, the solvent equal to the mass of the surfactant is weighed. Place the solvent in the second container, weigh the solvent of the remaining amount of the formula for the third time, and place it in the third container;

[0068] Step B, adding the nonylphenol polyether phosphate and the solvent in the first container into the first reaction kettle, and fully stirring, so that the nonylphenol polyeth...

Embodiment 2

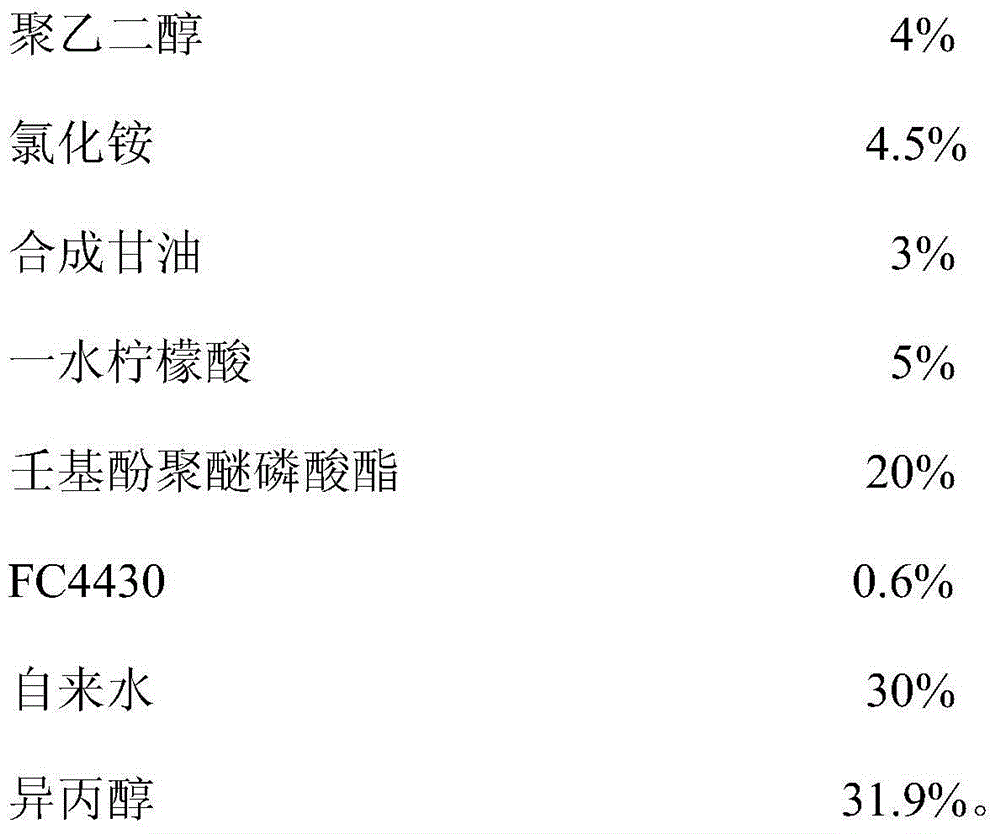

[0072] A kind of water-based soldering flux of the present invention comprises the raw material of following mass percentage:

[0073]

[0074] Wherein, the hindered phenolic antioxidant is antioxidant 1010.

[0075] A preparation method of water-based flux, comprising the following processing steps:

[0076] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0077] Among them, when weighing the solvent, it is weighed three times. For the first time, the solvent equal to the mass of nonylphenol polyether phosphate is weighed and placed in the first container. The second time, the solvent equal to the mass of the surfactant is weighed. Place the solvent in the second container, weigh the solvent of the remaining amount of the formula for the third time, and place it in the third container;

[0078] Step B, adding the nonylphenol polyether phosphate and the solvent in the first container into the first reaction...

Embodiment 3

[0082] A kind of water-based soldering flux of the present invention comprises the raw material of following mass percentage:

[0083]

[0084] Wherein, the antioxidant is a mixture of a phosphite antioxidant and a hindered phenolic antioxidant in a mass ratio of 1:1.

[0085] Preferably, the phosphite antioxidant is trioctyl, and the hindered phenol antioxidant is 2,6-di-tert-butyl-4-methylphenol.

[0086] A preparation method of water-based flux, comprising the following processing steps:

[0087] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0088] Among them, when weighing the solvent, it is weighed three times. For the first time, the solvent equal to the mass of nonylphenol polyether phosphate is weighed and placed in the first container. The second time, the solvent equal to the mass of the surfactant is weighed. Place the solvent in the second container, weigh the solvent of the remaining amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com