A sand box flip cleaning device for iron mold casting production line

A casting production line, inversion cleaning technology, applied in the direction of mold box, casting molding equipment, manufacturing tools, etc., to achieve the effect of eliminating potential safety hazards, realizing continuous operation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

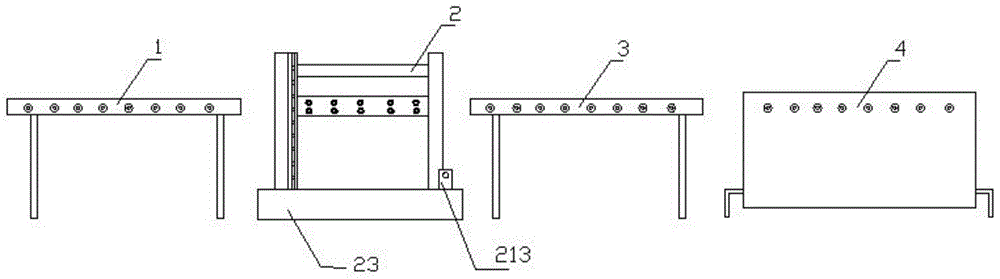

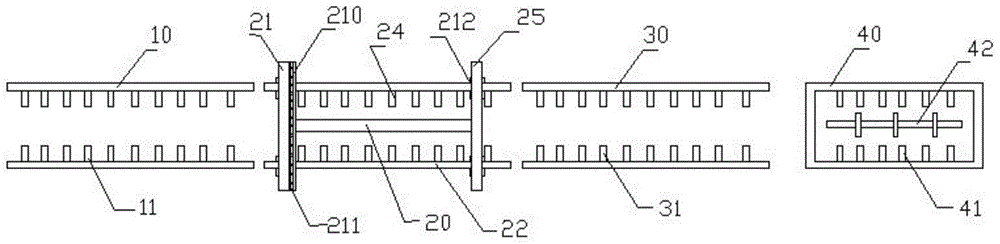

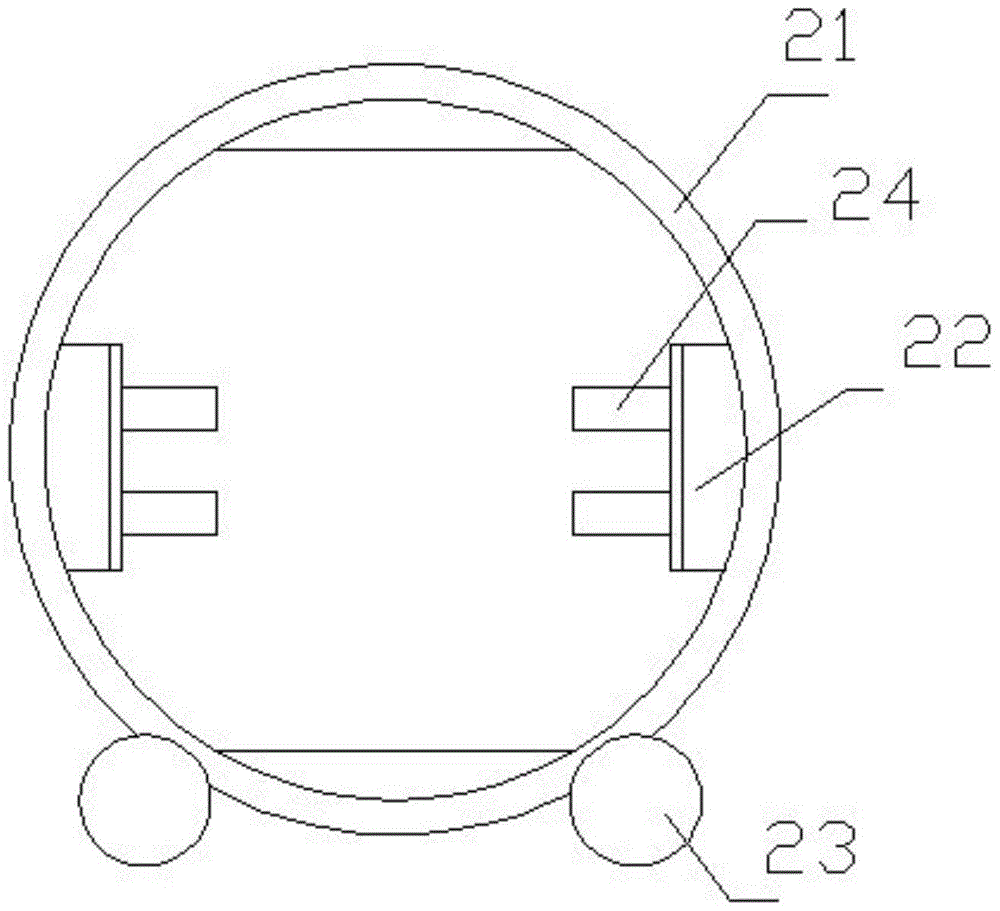

[0035] This embodiment includes a sand box feeding mechanism 1, a sand box turning mechanism 2, a sand box sending mechanism 3 and a sand box cleaning mechanism. According to the running direction of the sand box, the sand box sending mechanism 1 is located in front of the sand box turning mechanism 2, The sand box sending mechanism 3 is positioned at the rear of the sand box turning mechanism 2, and the sand box cleaning mechanism 4 is positioned at the rear of the sand box sending mechanism 3. Frame 23 and the rotating ring driving device that drives the rotating ring to rotate. Rotate on frame 23, described sand box support plate 22 is provided with roller table 24, and roller table 24 is made of a plurality of rollers. A plurality of rollers of the roller table 24 are driven by a roller table driving device, and the sand box is sent out by the rotation of the rollers. The sand box cleaning mechanism 4 includes a cleaning tank 40, a cleaning roller table 41 and a water spra...

Embodiment 2

[0044] This embodiment includes a sand box feeding mechanism 1, a sand box turning mechanism 2, a sand box sending mechanism 3 and a sand box cleaning mechanism. According to the running direction of the sand box, the sand box sending mechanism 1 is located in front of the sand box turning mechanism 2, The sand box sending mechanism 3 is positioned at the rear of the sand box turning mechanism 2, and the sand box cleaning mechanism 4 is positioned at the rear of the sand box sending mechanism 3. Frame 23 and the rotating ring driving device that drives the rotating ring to rotate. Rotate on frame 23, described sand box support plate 22 is provided with roller table 24, and roller table 24 is made of a plurality of rollers. The sand box on the sand box feeding mechanism 1 pushes the sand box on the sand box turning mechanism 2 to the sand box output mechanism 3, thereby realizing the continuous operation of the sand box turning. The sand box cleaning mechanism 4 includes a cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com