A Cold-Rolling Process for Preventing Broken Edge Defects of Ultra-thin Strip

An ultra-thin strip and broken edge technology, applied in the field of steel rolling, can solve the problems of reducing market competitiveness and rising production costs, and achieve the effects of reducing harmful contact stress, uniform pressure, and improving friction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

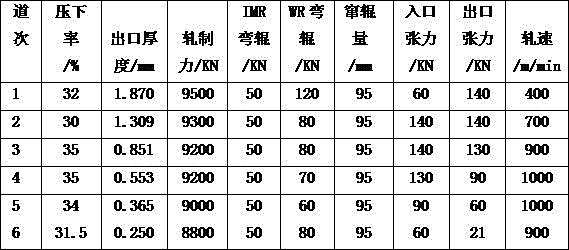

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below.

[0014] The cold-rolling process for preventing the chipped edge defect of the ultra-thin strip includes the following steps:

[0015] a) Set the temperature of the emulsion lubricated by the rolling mill to 55-58°C, the concentration to 2.5-4.0%, and the saponification value to 160-180mgKOH / g. Increase the temperature of the emulsion from 50-55°C to 55-58°C, the aggravation of the thermal movement of the rolling oil molecules and the clean emulsion sucked into the roll gap can increase the process lubrication effect at the limit pressure and improve the internal friction conditions of the roll gap , significantly reduce the rolling force of the pass; the appropriate increase in the temperature of the emulsion can reduce the cooling effect on the roll gap, increase the thermal crown of the roll, reduce the amount of flattening at both ends of the roll, reduce edge thinning, and prevent edge chipping wave defects. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com