Catalyst for synthesizing ethylidene diacetate

A technology of diethylene acetate and catalysts, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of low yield and selectivity of diethylene acetate low, high selectivity of diethylene acetate, etc., to improve activity and stability, improve yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of catalyst: NiCl containing 6.35gNi, 3.10gMo and 1.60gSn 2 6H 2 O, MoCl 5 and SnCl 2 2H 2 O is fully mixed and dissolved in acetic acid to obtain 500ml of impregnation solution, and 1.0L of spherical SiO with a diameter of 5.6mm 2 The carrier was immersed in the above impregnating solution, and stood for 2 h under N 2 The catalyst was obtained by raising the temperature to 500° C. and calcining for 4 h in the atmosphere.

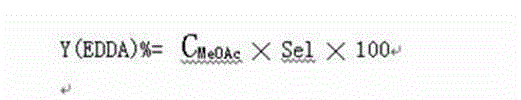

[0022] Synthesis of diethylene acetate: Add 1.5mol acetic acid, 0.05mol catalyst and 0.45mol methyl acetate into a 1.5L titanium reactor, first use argon to exhaust the air in the kettle, then pressurize to 2.0MPa, and then introduce carbon monoxide And hydrogen until the pressure is 8.0MPa, increase the stirring speed to 1500rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 175°C, the molar ratio of carbon monoxide to hydrogen is 3:1, continue the reaction for 7.5h, stop the reaction....

Embodiment 2

[0045] Preparation of catalyst: Ni(NO 3 ) 2 6H 2 O, MoO 3 and Sn(NO 3 ) 2 Fully mix and dissolve in dilute hydrochloric acid to obtain 500ml of impregnation solution, and 1.0L Al 2 o 3 The carrier was immersed in the above impregnating solution, left to stand for 2 hours, heated to 400° C. and calcined for 4 hours in a He atmosphere to obtain the catalyst.

[0046] Synthesis of diethylene acetate: Add 1.5mol acetic acid, 0.05mol catalyst and 0.45mol methyl acetate into a 1.5L titanium reactor, first use argon to discharge the air in the kettle, then pressurize to 1.0MPa, and then introduce carbon monoxide And hydrogen until the pressure is 2.0MPa, increase the stirring speed to 1500rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 130°C, the molar ratio of carbon monoxide to hydrogen is 1:10, continue the reaction for 3.0h, then stop the reaction.

[0047] Product analysis: The reaction mixture obtained from the above reac...

Embodiment 3

[0050] Preparation of catalyst: NiSO containing 15.0gNi, 5.00gMo and 5.00gSn 4 7H 2 O, MoO 3 Fully mixed with SnO and dissolved in concentrated hydrochloric acid to obtain 500ml of impregnating solution, and 1.0L Al 2 o 3 The carrier was immersed in the above impregnating solution, left to stand for 2 hours, and then heated to 600° C. for 4 hours in an Ar atmosphere to be calcined to obtain the catalyst.

[0051] Synthesis of diethylene acetate: Add 1.5mol acetic acid, 0.05mol catalyst and 0.45mol methyl acetate into a 1.5L titanium reactor, first use argon to exhaust the air in the kettle, then pressurize to 2.0MPa, and then introduce carbon monoxide And hydrogen until the pressure is 10.0MPa, increase the stirring speed to 1500rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 200°C, the molar ratio of carbon monoxide to hydrogen is 10:1, continue the reaction for 10.0h, stop the reaction.

[0052] Product analysis: The reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com