Preparation method of manganese oxide/porous carbon nanofiber composite material and product and application thereof

A technology of nanofibers and composite materials, which is applied in the field of preparation of oxide/porous carbon nanofiber composites, can solve the problems of high power density and high energy density loss, and achieve the effects of strengthening charge migration, protection and dissolution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

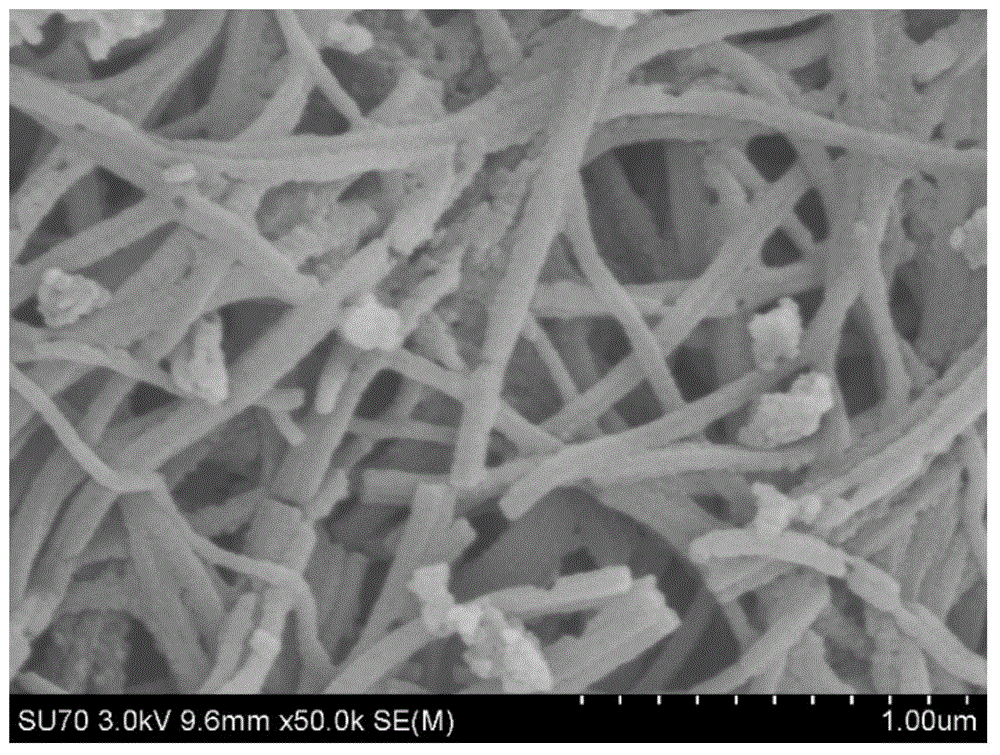

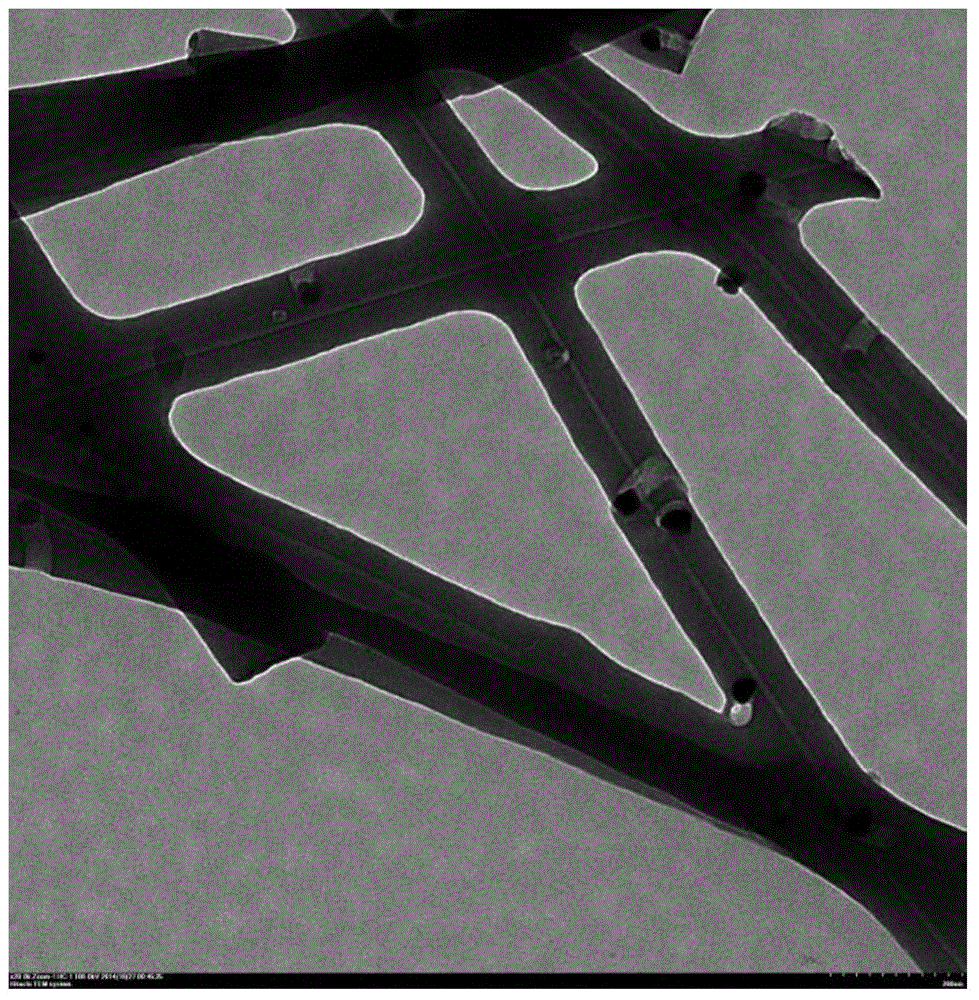

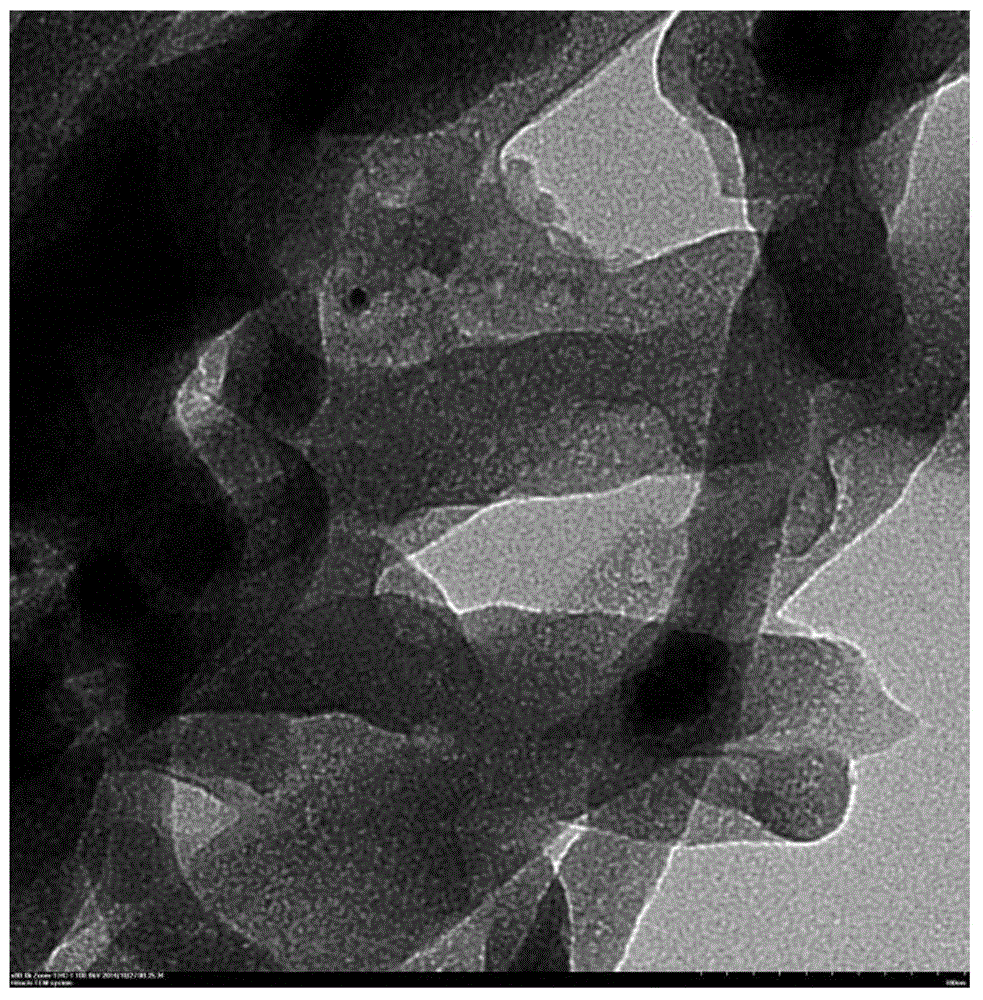

[0054] Add 1.5g of glucose, 40ml of deionized water, 0.1g of pelandas nanowires, 0.2g of F127, and 10mg of dopamine into a 50ml beaker, and stir to dissolve. dissolved in solution. The resulting solution was transferred to a reaction kettle, heated to 160°C, and reacted for 12 hours. After the reaction, the obtained precursor was washed with distilled water, then suction filtered, dried, and then carbonized at 900°C for 1 hour to obtain a manganese oxide / porous carbon nanofiber composite material. The scanning electron microscope image of the product is shown in figure 1 , see the transmission electron micrograph figure 2 and 3 . from figure 2 We can clearly see the manganese oxide / carbon nanofiber structure in which image 3 is the enlarged TEM image from image 3 We can see the obvious mesoporous structure. Figure 4 The specific surface area of the product obtained by the low-temperature nitrogen adsorption and desorption test is given in , and the specific surfa...

Embodiment 2

[0056] Add 1.5g of glucose, 40ml of deionized water, 0.1g of pelandas nanowires, 0.2g of F127, and 10mg of dopamine into a 50ml beaker, and stir to dissolve. dissolved in solution. The resulting solution was transferred to a reaction kettle, heated to 160°C, and reacted for 12 hours. After the reaction, the obtained precursor was washed with distilled water, then suction filtered, dried, and then carbonized at 700°C for 1 h to obtain a manganese oxide / porous carbon nanofiber composite material. Figure 7 The specific surface area of the product obtained by the low-temperature nitrogen adsorption and desorption test method is given in , and the specific surface area can reach 501m 2 / g. The pore volume ratio of micropores and mesopores is 0.18:0.82. It shows that we can control the pore structure and specific surface area of the product by adjusting the calcination temperature.

Embodiment 3

[0058] Add 0.5g of glucose, 40ml of deionized water, 0.1g of pelandas nanowires, 0.2g of F127, and 10mg of dopamine into a 50ml beaker, and stir to dissolve. dissolved in solution. The resulting solution was transferred to a reaction kettle, heated to 160°C, and reacted for 12 hours. After the reaction, the obtained precursor was washed with distilled water, then suction-filtered, dried, and carbonized at 900°C for 1 h to obtain a manganese oxide / porous carbon nanofiber composite material, but the yield of the product was low. The scanning electron microscope image of the product is shown in Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com