Method for measuring content of sodium tetraborate in sintering promoting agent

A technology of sintering synergist and sodium tetraborate, which is applied in chemical analysis by titration, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problem of blast furnace ironmaking Damage and other problems, to achieve the effect of short operation process, accurate results, accurate and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

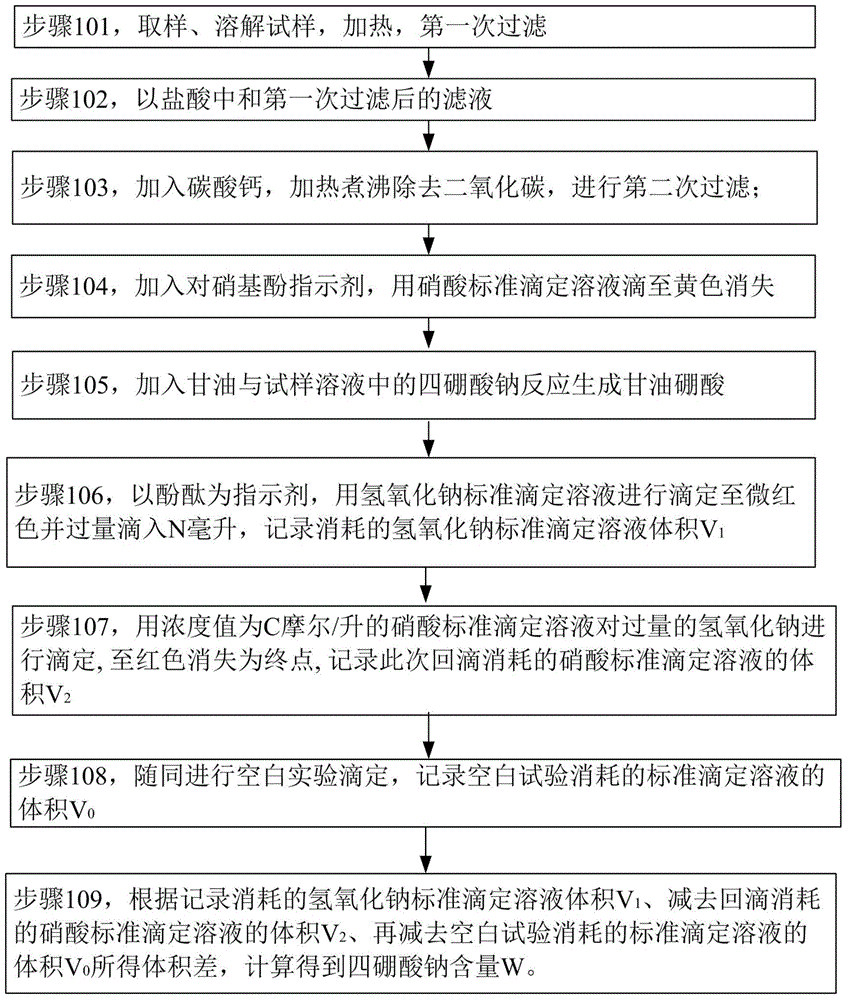

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] In the prior art, there is no standard determination method for the determination of sodium tetraborate in the sintering synergist for the time being, so it is necessary to find a rapid determination method for fast, accurate and efficient determination of sodium tetraborate in the sintering synergist in production basis is provided.

[0024] This method is based on the acid-base titration test, firstly dissolve the sample with water, filter after heating and cooling, neutralize the filtrate with hydrochloric acid, heat and boil to remove carbon dioxide and then filter again; add p-nitrophenol indicator to the filtrate, titrate with nitric acid standard Drop the solution until the yellow color disappears, add glycerol and sodium tetraborate to react to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com