Oil Shale Semi-coke Fluidized Combustion Heat Pipe Circulating Gas Heating Furnace

A technology for oil shale semi-coke and fluidized combustion, which is applied in fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., to achieve the effects of high heat transfer efficiency, low fluid resistance and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

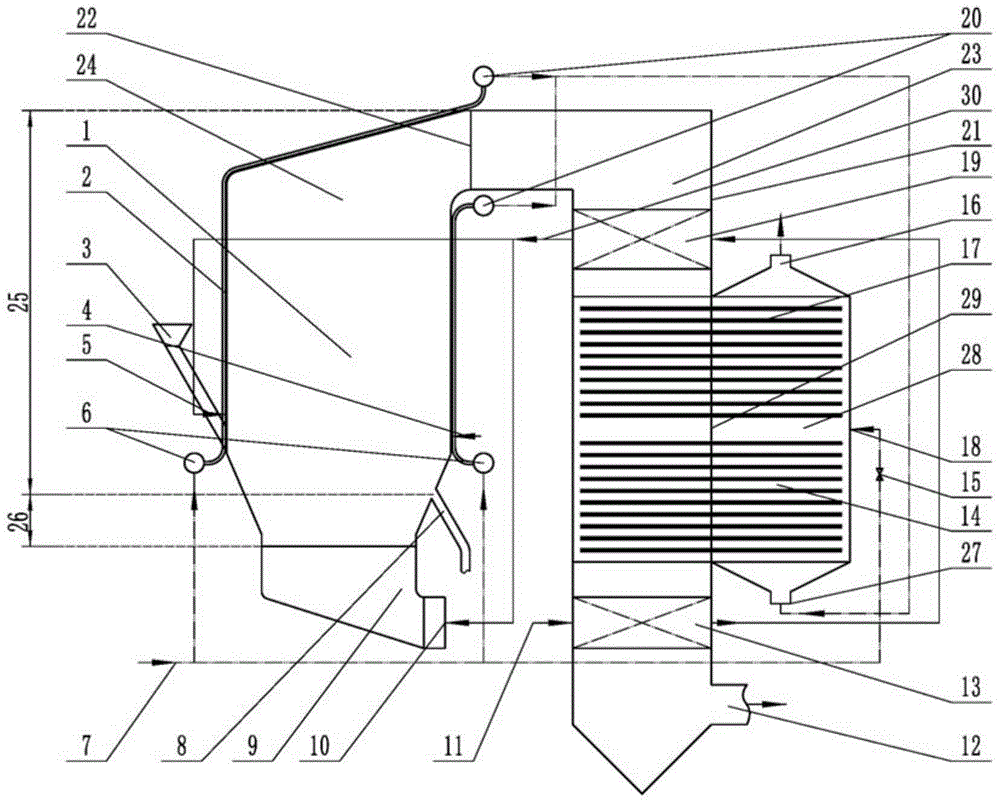

[0023] The present invention will be further described below using the accompanying drawings and examples.

[0024] The oil shale semi-coke fluidized combustion heat pipe type circulating gas heating furnace of the present invention comprises that the furnace outlet 22 of the fluidized bed combustion furnace 24 communicates with the inlet of the tail heat exchanger 23, and the fluidized bed combustion furnace 24 comprises a furnace 1, a cloth Air device 9, secondary air nozzle 5, residual gas burner 4, feed pipe 3 and slag discharge overflow pipe 8, the lower end of furnace 1 is connected to air distribution device 9, the front wall of furnace 1 is provided with feed pipe 3, and the rear The wall is provided with a slagging overflow pipe 8, the upper part of the furnace 1 is a dilute-phase area 25, and the lower part is a dense-phase area 26. The bottom of the dilute-phase area 25 is provided with a residual gas burner 4 and a secondary air nozzle 5. The dilute-phase area 25 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com