Universal joint inclined strut capable of being conveniently applied inside and outside supporting frame

A general-purpose node and support frame technology, which is applied in the direction of house structure support, house structure support, scaffolding accessories, etc., to achieve the effects of reducing costs, reinforcing the loss of joint stiffness, and reducing the probability of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

[0030] An office building of this project has a frame-shear structure with one basement floor and 15 floors above ground; the total area is about 12845.6 square meters.

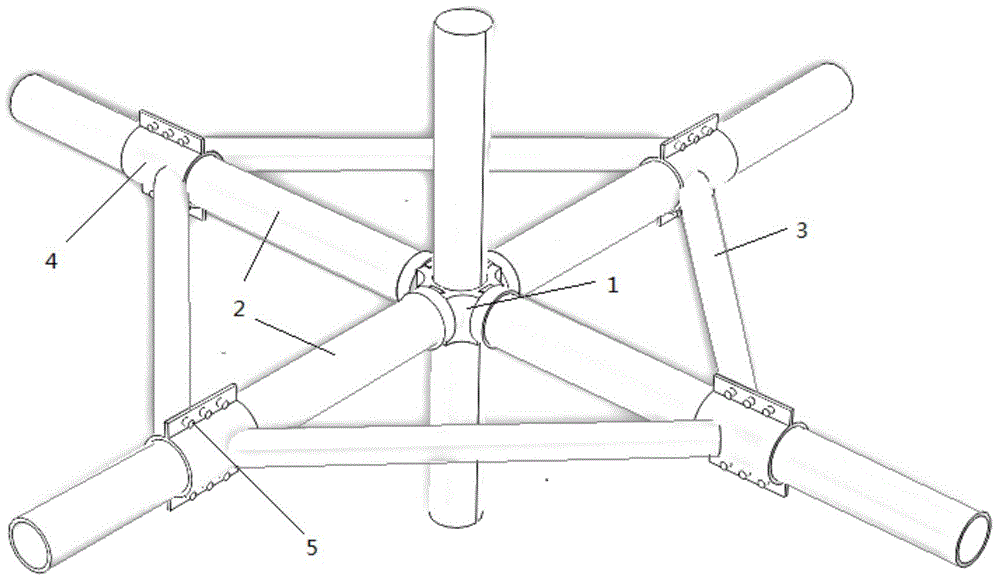

[0031] The components involved in this scaffolding project: (1) The steel pipe adopts No. 3 steel welded steel pipe with an outer diameter of 48mm and a wall thickness of 3.5mm. The length of the steel pipe of the vertical pole and the longitudinal horizontal pole (large cross-bar) is generally 4-6m, and the horizontal horizontal pole (small cross-bar) is generally 1.9-2.3m. The steel pipe is coated with anti-rust paint. ⑵Scaffolding load: 3kN / m for structural frame 2 , The decoration is 2kN / m 2 . (3) The diagonal brace is the universal node diagonal brace of the supporting frame described in the present invention.

[0032] The erection sequence of the supporting frame of this project: the foundation is a 200-thick plain concrete dispersing water slope, the base is placed (the thickness of 50 solid wood slabs ar...

application example 2

[0036] One of the overpass main girder of a certain bridge project is a C50 uniform cross-section prestressed reinforced concrete continuous box girder, single box multi-chamber, box girder top plate width 36.1 meters, bottom plate width 31.1 meters, cantilever length on both sides is 2.5 meters, beam height 2 Meters, the top thickness of the box girder is 0.25 meters, and the bottom thickness is 0.2 meters.

[0037] The components and material requirements involved in this scaffolding project: ⑴The steel pipe for the new scaffold adopts Q235A grade ordinary steel pipe, the specification is Φ48×3.5mm, and the wall thickness of the steel pipe shall not be less than 3.475mm. ⑶ The top support, adjustable base and adjustable support nut are made of malleable cast iron. Crossbar joints and diagonal rod joints are made of carbon cast steel. ⑷The diagonal brace is the joint use of the universal node diagonal brace of the support frame and the ordinary scissors brace in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com