Degreasing agent for stainless steel, carbon steel and petrochemical pipelines

A petrochemical and degreasing agent technology, applied in the field of chemical product preparation, can solve the problems of poor degreasing performance, physical harm to operators, poor high temperature performance, etc., and achieves green and environmentally friendly raw material sources, reduces physical harm, and has high degreasing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

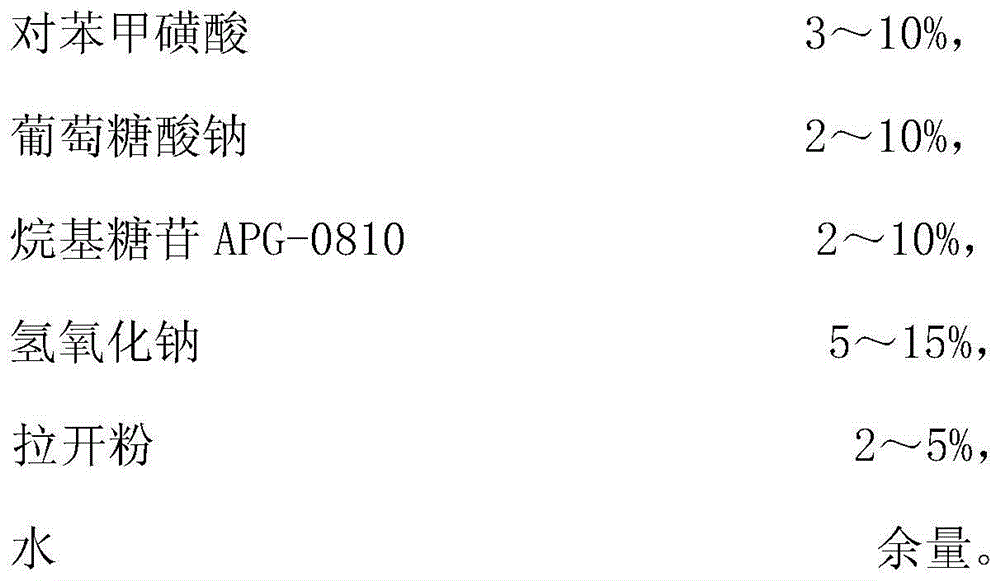

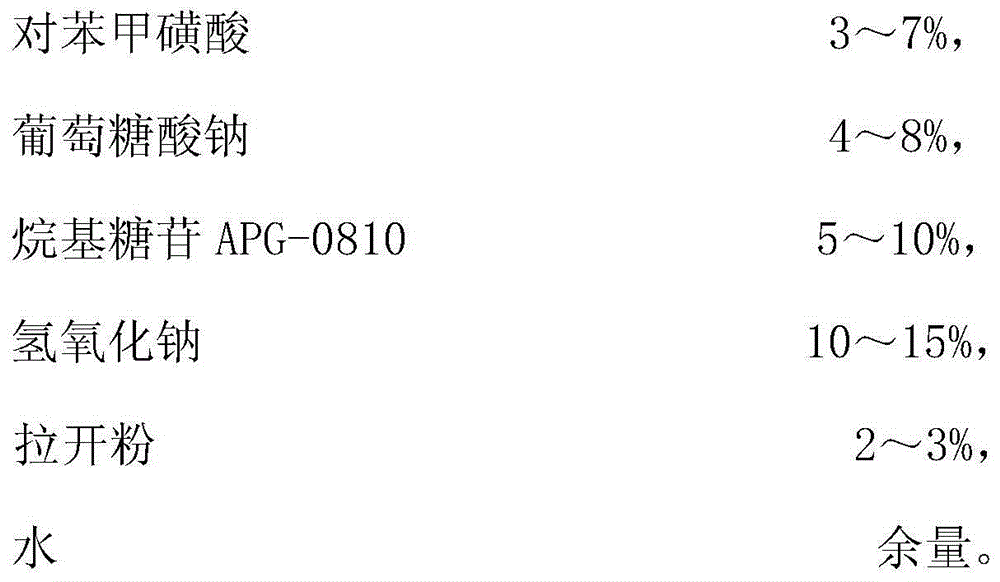

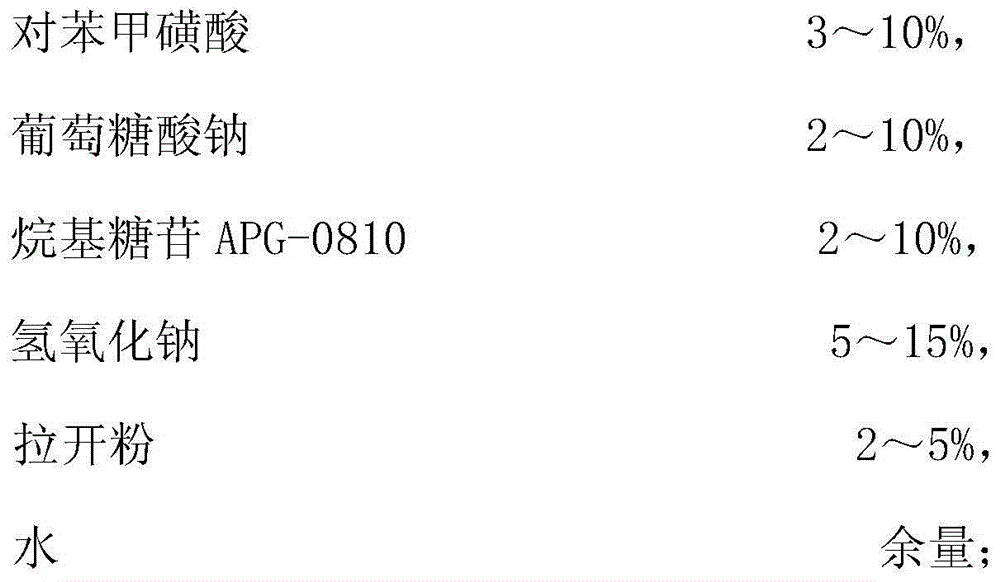

Method used

Image

Examples

Embodiment 1

[0014] Weigh 100g of sodium hydroxide, 40g of sodium gluconate, 20g of pull-off powder, 30g of p-phenylmethanesulfonic acid, and 50g of alkyl glycoside APG-081050g. The p-phenylmethanesulfonic acid is dissolved in sodium hydroxide solution, cooled to room temperature and packaged, then the product is ready. Take the degreasing agent product in Example 1 and dilute it into 1000mL of 10% aqueous solution, soak the carbon steel or stainless steel elbow of DN30 pickled by hydrochloric acid at room temperature for 30min, take out the elbow, rinse it with pure water, and then dry it with oil-free air Blow dry, soak the dry elbow 10min with 1000mL carbon tetrachloride, then measure the oil content in the carbon tetrachloride to be 10mg / L, which is far better than the degreasing agent currently used (sodium hydroxide 60g, sodium carbonate 40g, nonyl phenol polyoxyethylene ether OP-1020g, 880mL water compounded, the same below) the oil content (245mg / L, the same below) determined by th...

Embodiment 2

[0016] Weigh 150g of sodium hydroxide, 30g of pull-off powder, 80g of alkyl glycoside APG-081080g, 70g of p-phenylmethanesulfonic acid, and 80g of sodium gluconate. Sulfonic acid, APG-0810 and sodium gluconate are dissolved in sodium hydroxide solution, cooled to room temperature and packaged, then the product is ready. Take the degreasing agent product in Example 2 and dilute it into 1000mL of 10% aqueous solution, soak the carbon steel or stainless steel elbow of DN30 pickled by hydrochloric acid at room temperature for 30min, take out the elbow, rinse it with pure water, and then dry it with oil-free air Blow dry, soak the dry elbow with 1000mL carbon tetrachloride for 10min, and then measure the oil content in carbon tetrachloride to be 8mg / L, which is far superior to the oil content measured by the same method for the degreasing agent currently used.

Embodiment 3

[0018] Weigh 100g of sodium hydroxide, 50g of alkyl glycoside APG-0810, 30g of pull-off powder, 65g of p-phenylmethanesulfonic acid, 70g of sodium gluconate, first dissolve sodium hydroxide in 685mL of water, and then dissolve Dissolve powder, p-benzenemethanesulfonic acid and sodium gluconate in sodium hydroxide solution, cool to room temperature and package, then the product is ready. Take the degreasing agent product in Example 3 and dilute it into 1000mL of 10% aqueous solution, soak the carbon steel or stainless steel elbow of DN30 pickled by hydrochloric acid at room temperature for 30min, take out the elbow, rinse it with pure water, and then dry it with oil-free air Blow dry, soak the dry elbow with 1000mL carbon tetrachloride for 10min, and then measure the oil content in carbon tetrachloride to be 15mg / L, which is far superior to the oil content measured by the same method for the degreasing agent currently used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com