Clean coal pressurized fluidized bed slag gasification process and system

A technology of pressurized fluidized bed and fluidized bed gasifier, which is applied in gasification process, gasification device details, granular/powder fuel gasification, etc., can solve the problem of low gasification efficiency, carbon conversion rate and gas The problems such as low gasification efficiency and large steam consumption can reduce the blockage and occurrence of subsequent pipelines and equipment, improve the thermal efficiency of gasification, and achieve the effect of high steam decomposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

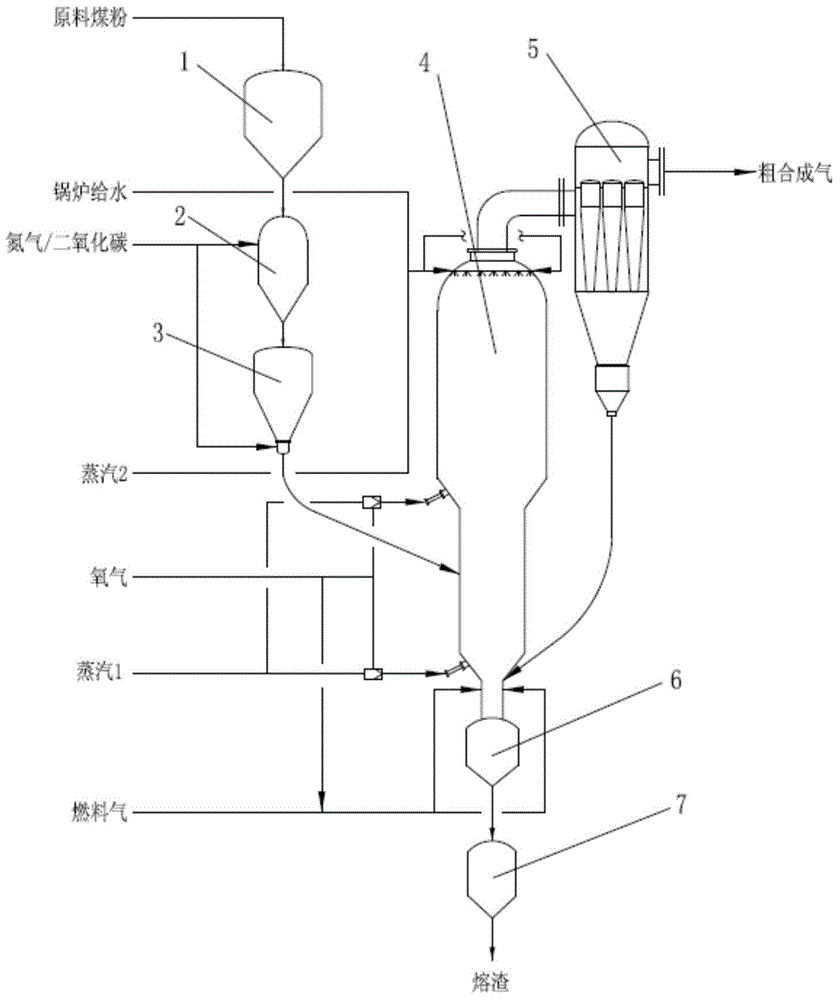

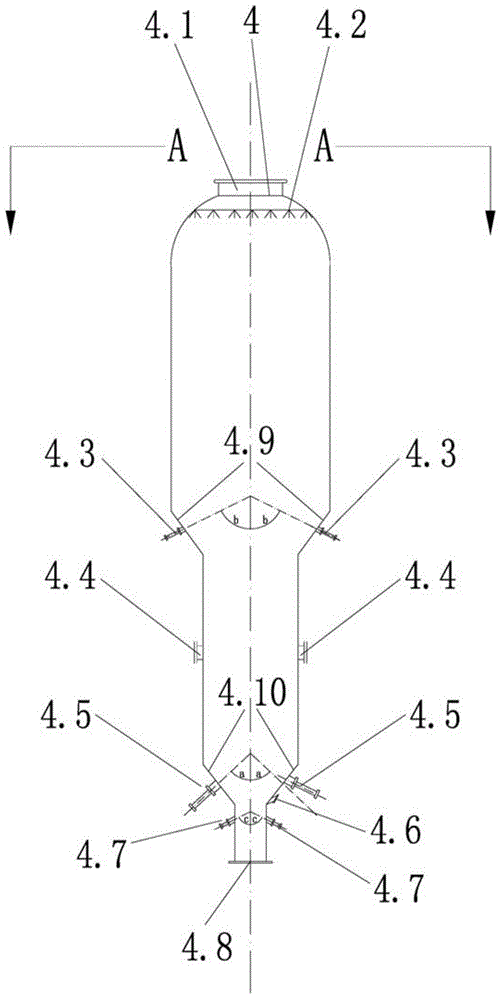

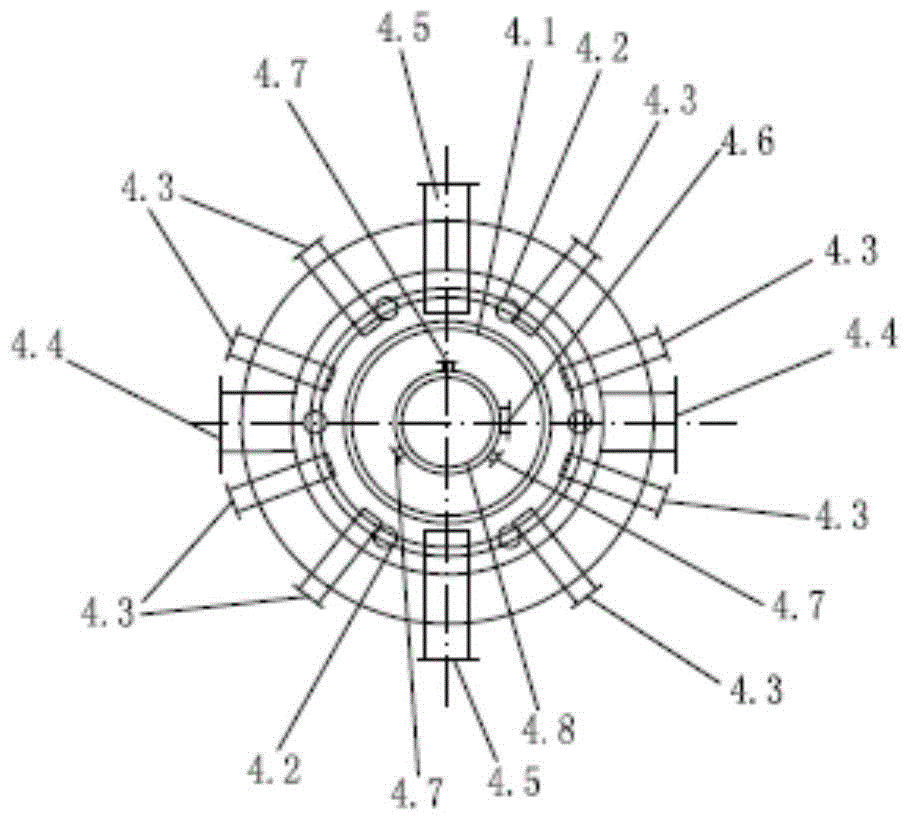

[0032] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0033] refer to figure 1 , the pulverized coal bin 1, the pulverized coal lock hopper 2, the pulverized coal feed tank 3 and the feed port 4.4 of the fluidized bed gasification furnace 4 are connected in sequence, and the raw pulverized coal is transported to the fluidized bed gasification furnace 4 by airflow for further processing. Gasification reaction, the gasification agent (the mixture of oxygen and steam) enters the fluidized bed gasification furnace 4 through the primary nozzle interface 4.5 and the secondary nozzle interface 4.3 of the gasification furnace, and the raw coal entering the fluidized bed gasification furnace 4 powder for gasification reaction, the top outlet of the fluidized bed gasifier 4 is connected to the multi-tubular cyclone separator 5, and the bottom outlet is sequentially connected to the slag quenching tank 6 and the slag lock hopper 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com