Novel desulfurizing tower

A new type of desulfurization and desulfurization tower technology, applied in the field of desulfurization towers, can solve the problem that small droplets are difficult to solidify, and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

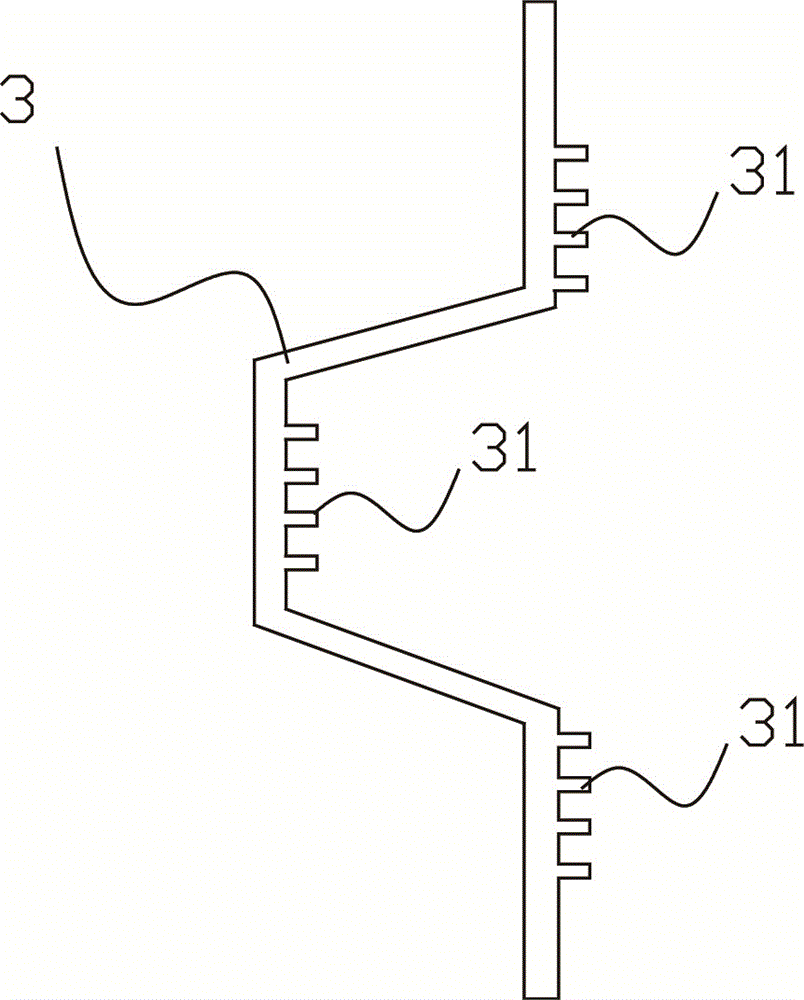

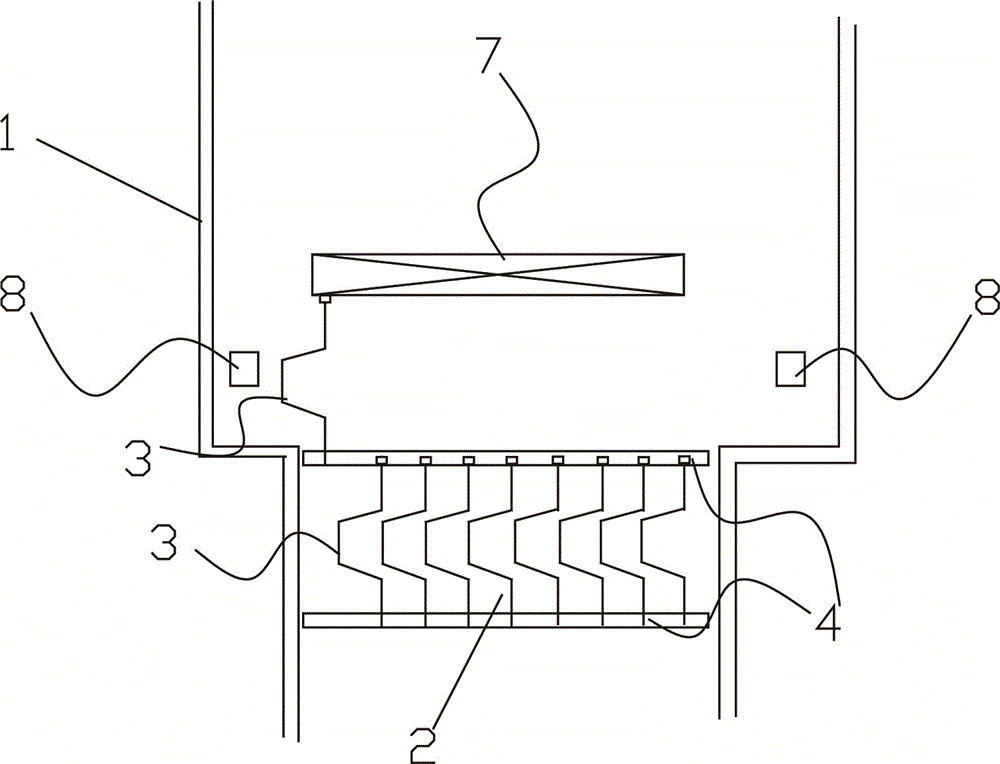

[0024] Example 2: see Figure 2 to Figure 8 , a chute 40 is provided on the support frame 4 so that the blade 3 can slide longitudinally along the support frame, and the blade 3 includes a slide rail 30 provided on its side wall, the slide rail 30 cooperates with the slide groove 40 , and the slide rail 30 extends in the vertical direction of the side wall and covers the entire longitudinal direction of the blade 3 . Wherein the distance between the blades 3 is kept such that when any blade 3 slides in the vertical direction, there is no interference with its adjacent blades.

[0025] A blocking piece 5 is arranged above the chute 40, and a reset mechanism is provided on the blocking piece 5 so that it has a tendency to break away from the chute 40. A push rod 6 is arranged on one side of the blocking piece 5. The side of the rod 6 is provided with a catch groove 60 that matches the catch 5. Specifically, the catch groove 60 is distributed along the longitudinal interval of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com