Gasification furnace structure capable of treating pulverized coal and water coal slurry simultaneously

A simultaneous processing and gasification furnace technology, which is applied in the direction of granular/powdered fuel gasification, gasification process, and the manufacture of combustible gas, can solve the problems of high comprehensive energy consumption, high requirements for coal quality in the furnace, and large investment. Achieve the effects of large processing capacity, strong adaptability to coal types, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

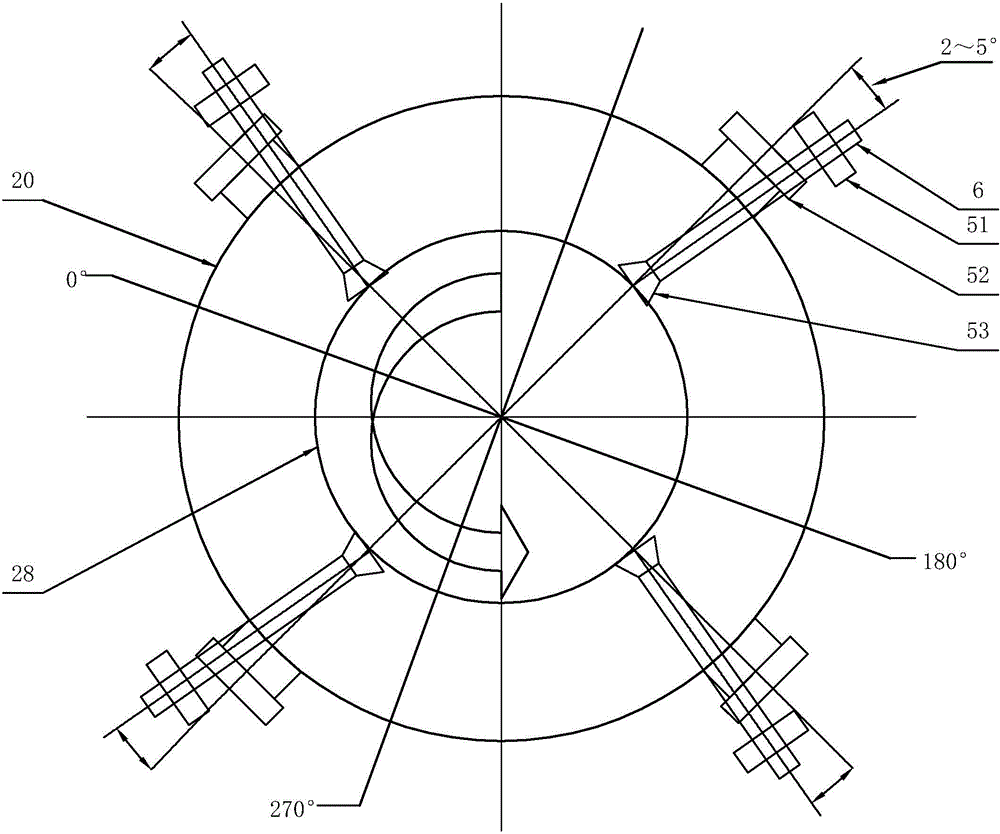

[0037] Such as Figure 1 to Figure 11 As shown, the structure of the gasifier capable of simultaneously processing pulverized coal and coal-water slurry includes:

[0038] The furnace body 20 made of pressure shell, the upper part of the furnace body 20 is provided with a water-cooled wall 28, the water-cooled wall 28 surrounds and forms a gasification chamber 29, and the gap between the water-cooled wall 28 and the furnace body 20 forms an annular space 18; Inside the space 18, a saturated boiler water main pipe / distribution pipe 34 and a steam-water mixture main pipe / distribution pipe 33 are installed.

[0039] The structures of the saturated boiler water main pipe / distribution pipe 34 and the steam-water mixture main pipe / distribution pipe 33 can be selected from any one of the prior art as required. In this embodiment, the saturated boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com