Modification quality upgrading system of brown coal

A modification and upgrading technology, applied in the direction of direct heating dry distillation, special form dry distillation, coke oven, etc., can solve the problem that the polluting gas and dust cannot be effectively treated, the efficiency of sulfur and mercury is low, and the heat of boiler exhaust gas cannot be obtained. Effective utilization and other issues, to achieve the effect of high-efficiency and low-pollution development and utilization, system stability, and reducing the difficulty of manufacturing and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

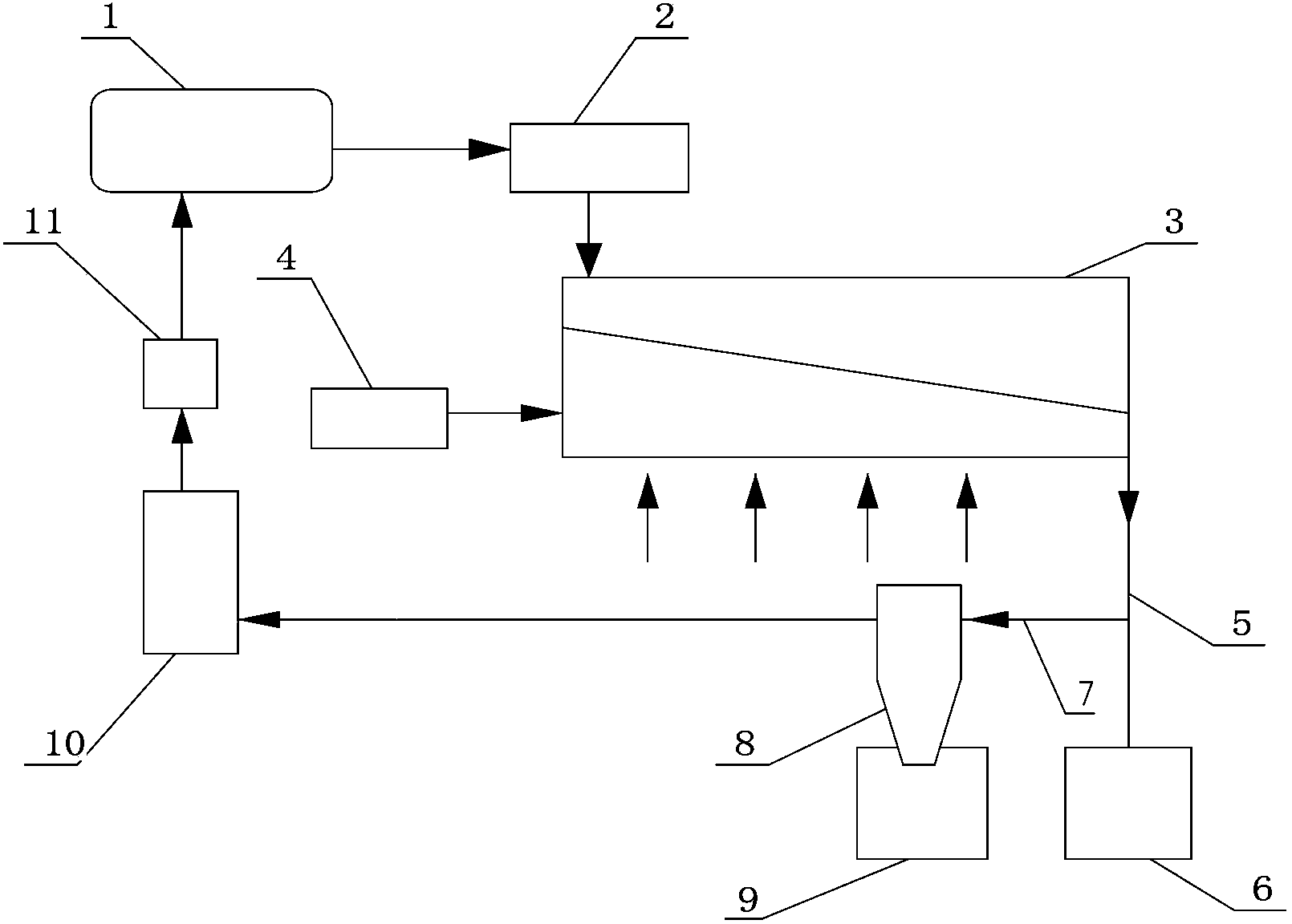

[0014] Such as figure 1 As shown, the embodiment of the present invention includes a raw coal bunker 1, a feeding device 2, a fluidized pyrolysis device 3, a constant flow pump 4, a vertical pipeline 5, a primary upgrading coal bunker 6, a horizontal pipeline 7, and a cyclone separator 8. The secondary upgrading coal bunker 9, the gas purification device 10 and the induced draft fan 11; the raw coal bunker 1, the feeding device 2 and the fluidized pyrolysis device 3 are sequentially connected through pipelines;

[0015] Such as figure 2 As shown, the fluidized pyrolysis device 3 is composed of a resistance heating furnace 3-1, a closed box 3-2 and an air distribution plate 3-3, and the closed box 3-2 is located in the resistance heating furnace 3-1 , the left side of the upper end surface 3-2-1 of the closed box has a material inlet 3-4, the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com