A composite foam dust remover

A kind of dedusting agent and composite technology, applied in the field of composite foam dedusting agent, can solve the problems of electromechanical equipment corrosion, increase dust removal cost, electromechanical equipment cost, poor wettability, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

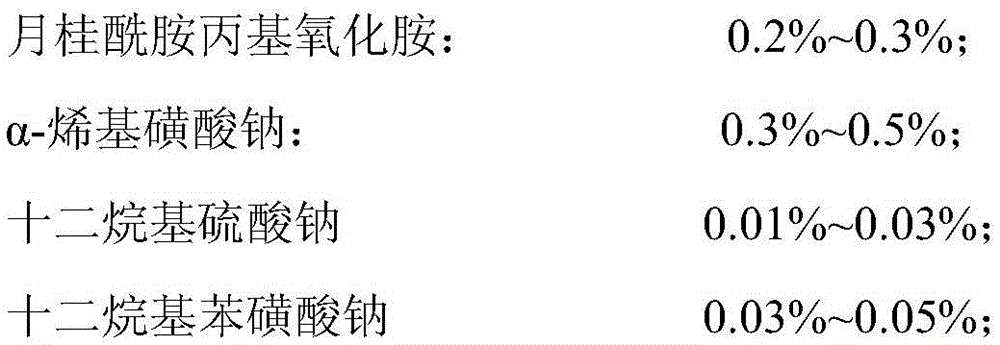

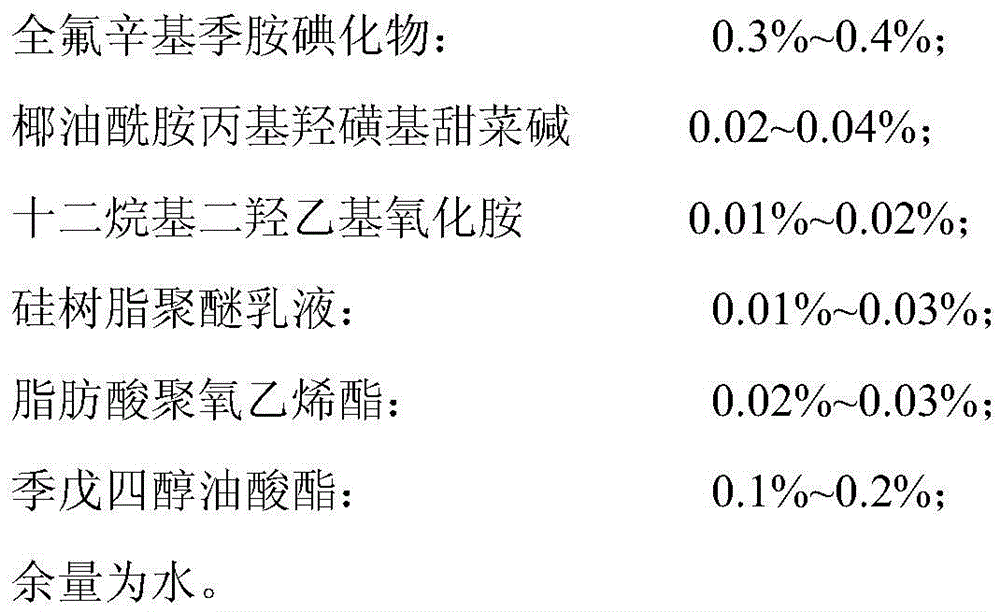

Method used

Image

Examples

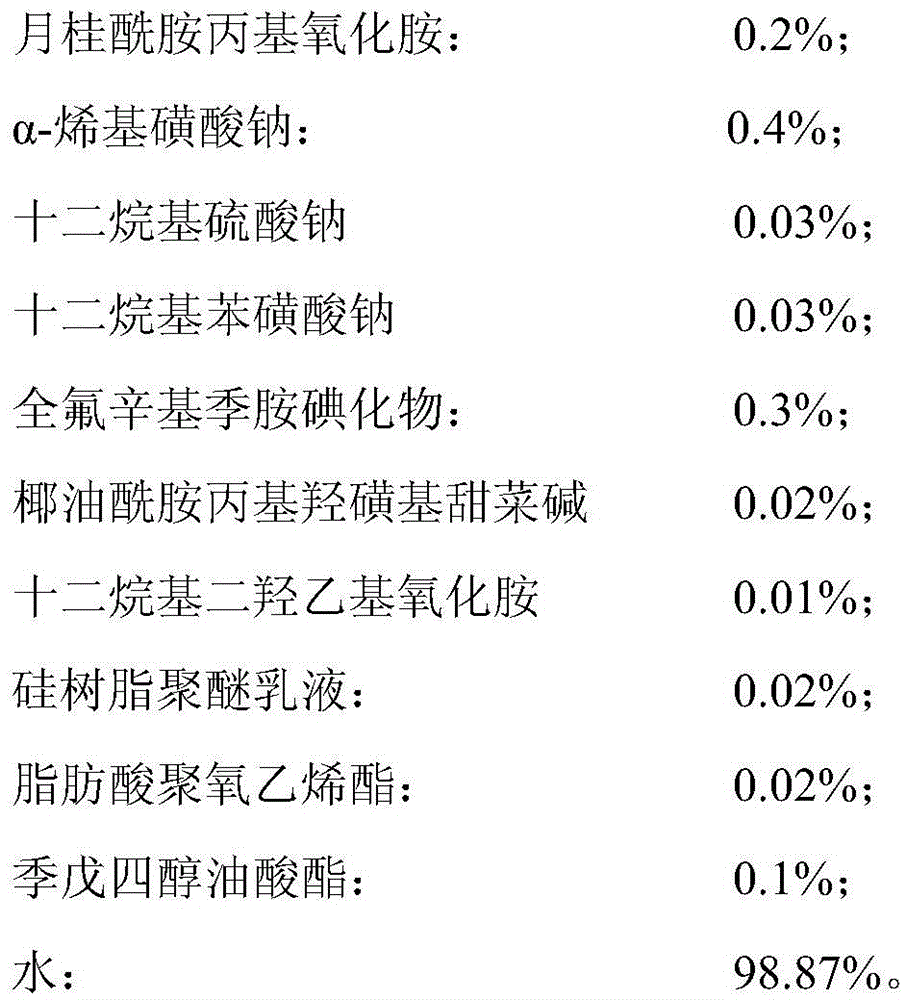

Embodiment 1

[0025]Take 2kg of lauryl amidopropyl amine oxide, 4kg of sodium α-olefin sulfonate, 0.3kg of sodium dodecyl sulfate, 0.3kg of sodium dodecylbenzenesulfonate, 3kg of perfluorooctyl quaternary ammonium Iodide, 0.2kg of cocamidopropyl hydroxysultaine, 0.1kg of lauryl dihydroxyethyl amine oxide, 0.2kg of silicone resin polyether emulsion, 0.2kg of polyoxyethylene fatty acid ester and 1kg The pentaerythritol oleate was added to 988.7kg of water, mixed thoroughly and heated slightly to dissolve completely, and finally configured into 1000kg of foam dust remover for wet dust removal. In the foam dust remover, the proportion of lauryl amidopropyl amine oxide is 0.2%, the proportion of sodium α-alkenyl sulfonate is 0.4%, and the proportion of sodium lauryl sulfate is 0.03%. The proportion of sodium dodecylbenzenesulfonate is 0.03%, the proportion of perfluorooctyl quaternary ammonium iodide is 0.3%, and the proportion of cocamidopropyl hydroxysultaine is 0.02%. The proportion of dodec...

Embodiment 2

[0029] Take 3kg of lauryl amidopropyl amine oxide, 4kg of sodium α-olefin sulfonate, 0.2kg of sodium dodecyl sulfate, 0.4kg of sodium dodecylbenzenesulfonate, 4kg of perfluorooctyl quaternary ammonium Iodide, 0.4kg of cocamidopropyl hydroxysultaine, 0.2kg of lauryl dihydroxyethyl amine oxide, 0.1kg of silicone resin polyether emulsion, 0.3kg of fatty acid polyoxyethylene ester and 2kg The pentaerythritol oleate was added to 985.4kg of water, mixed thoroughly, heated slightly to dissolve completely, and finally configured into 1000kg of foam dust remover for wet dust removal. In the foam dust remover, the proportion of lauryl amidopropyl amine oxide is 0.3%, the proportion of sodium α-olefin sulfonate is 0.4%, and the proportion of sodium lauryl sulfate is 0.02%. The proportion of sodium dodecylbenzenesulfonate is 0.04%, the proportion of perfluorooctyl quaternary ammonium iodide is 0.4%, and the proportion of cocamidopropyl hydroxysultaine is 0.04%, The proportion of dodecyl ...

Embodiment 3

[0034] Take 3kg of lauryl amidopropyl amine oxide, 3kg of sodium α-olefin sulfonate, 0.1kg of sodium dodecyl sulfate, 0.3kg of sodium dodecylbenzenesulfonate, 4kg of perfluorooctyl quaternary ammonium Iodide, 0.3kg of cocamidopropyl hydroxysultaine, 0.1kg of lauryl dihydroxyethyl amine oxide, 0.2kg of silicone resin polyether emulsion, 0.3kg of fatty acid polyoxyethylene ester and 2kg The pentaerythritol oleate was added to 986.7kg of water, mixed thoroughly, heated slightly to dissolve completely, and finally configured into 1000kg of foam dust remover for wet dust removal. In the foam dust remover, the proportion of lauryl amidopropyl amine oxide is 0.3%, the proportion of sodium α-alkenyl sulfonate is 0.3%, and the proportion of sodium lauryl sulfate is 0.01%. The proportion of sodium dodecylbenzenesulfonate is 0.03%, the proportion of perfluorooctyl quaternary ammonium iodide is 0.4%, and the proportion of cocamidopropyl hydroxysultaine is 0.03%. The proportion of dodecyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com