Epoxy resin encapsulating material as well as preparation method and application thereof

A technology of epoxy resin and potting material, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of capacitance drop, affecting the service life, etc., achieve low shrinkage and hygroscopicity, improve resistance Heat and moisture resistance, effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

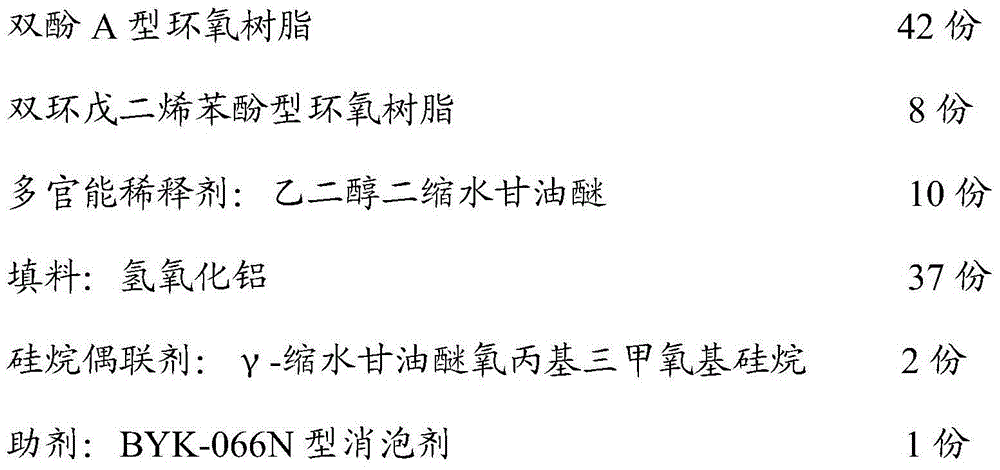

[0042] An epoxy resin potting material is prepared from the following raw materials in parts by weight:

[0043] Resin part:

[0044]

[0045] Curing agent part:

[0046] Methyl nadic anhydride 90 parts

[0047] Cycloaliphatic epoxy resin 7 parts

[0048]Accelerator: 2,4,6-tris(dimethylaminomethyl)phenol 3 parts

[0049] The resin part and the curing agent part are mixed in parts by weight of 100:40.

[0050] The above-mentioned epoxy resin potting material is prepared by the following method:

[0051] In the preparation of the resin part, after adding the multifunctional diluent, silane coupling agent, and bisphenol A epoxy resin with a predetermined addition amount of 60% into the reaction vessel, the temperature was raised to 115° C., while stirring at a stirring speed of 400 rpm Add filler, then vacuumize while stirring, react for 3.5 hours, the vacuum degree is 730mmHg, then after cooling down to 45°C, add additives (commercially available BYK-066N defoamer) and t...

Embodiment 2

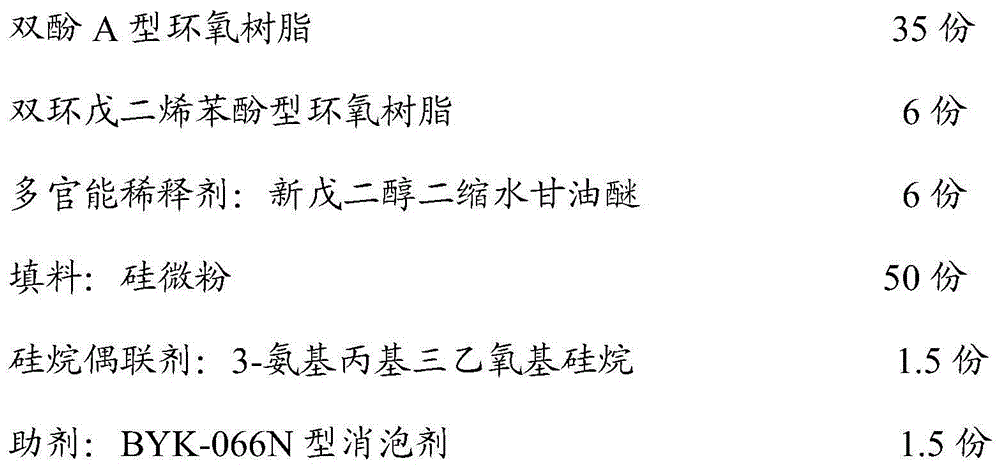

[0056] An epoxy resin potting material is prepared from the following raw materials in parts by weight:

[0057] Resin part:

[0058]

[0059] Curing agent part:

[0060] Methyltetrahydrophthalic anhydride 89 parts

[0061] Cycloaliphatic epoxy resin 5 parts

[0062] Accelerator: 2 parts of dimethylimidazole

[0063] The resin part and the curing agent part are mixed in parts by weight of 100:35.

[0064] The above-mentioned epoxy resin potting material is prepared by the following method:

[0065] In the preparation of the resin part, after adding multifunctional diluent, silane coupling agent, bisphenol A type epoxy resin and dicyclopentadiene phenol type epoxy resin in predetermined addition amount of 50%, the temperature is raised to 110 ℃, add filler while stirring at a stirring speed of 350rpm, then vacuumize while stirring, react for 4.5h, the vacuum degree is 700mmHg, then cool down to 40℃, add additives and the remaining bisphenol A epoxy Resin and dicyclopen...

Embodiment 3

[0070] An epoxy resin potting material is prepared from the following raw materials in parts by weight:

[0071] Resin part:

[0072]

[0073]

[0074] Curing agent part:

[0075]

[0076] The resin part and the curing agent part are mixed in parts by weight of 100:45.

[0077] The above-mentioned epoxy resin potting material is prepared by the following method:

[0078] In the preparation of the resin part, after adding the multifunctional diluent, silane coupling agent, and bisphenol A epoxy resin with a predetermined amount of 70% into the reaction vessel, the temperature was raised to 130°C and stirred at a stirring speed of 450rpm Add filler at the same time, then vacuumize while stirring, react for 2 hours, the vacuum degree is 760mmHg, then after cooling down to 60°C, add additives and the remaining bisphenol A type epoxy resin and dicyclopentadiene phenol type epoxy Resin, discharged, ready to use.

[0079] In the preparation of the curing agent part, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com