Freezing method of material with microcosmic lamellar structure

A freezing method and a layered structure technology are applied in the field of freezing for preparing materials with a microscopic layered structure, and can solve problems such as single microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

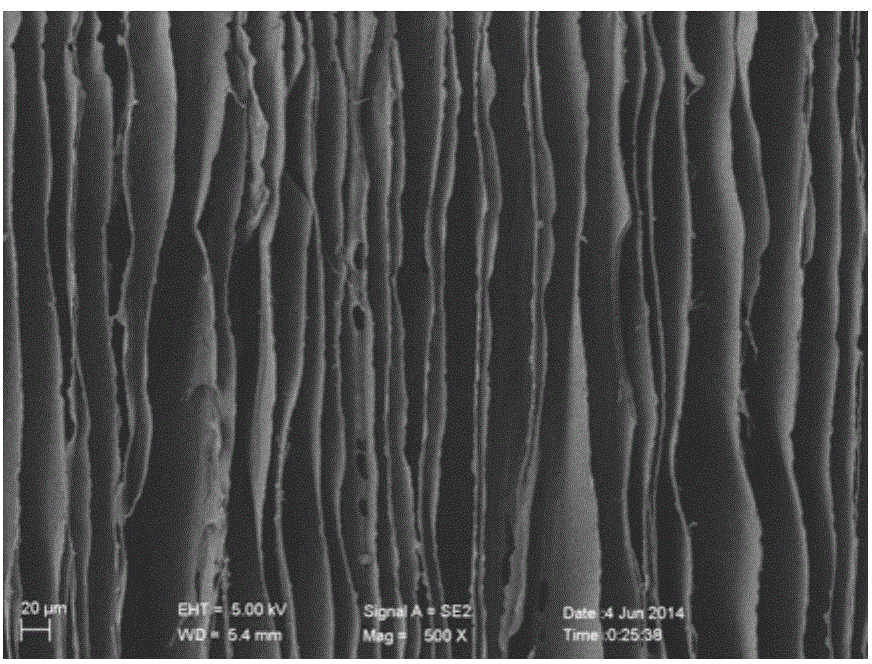

[0025] Prepare 100mL of chitosan solution of 20mg / mL; 3 ) installed on the freezing surface of the stainless steel freezing device; pour 4mL of prepared chitosan solution into the mold, and then cool down with liquid nitrogen from one end of the freezing surface to -100°C, so that the freezing point from one end of the freezing surface Move to the other end, so that the ice in the mold grows along one end of the freezing surface to the other end until the solution in the entire mold is completely frozen; put the frozen ice cubes in a vacuum freeze dryer for deicing and drying After 48 hours, the layered chitosan scaffold material can be obtained, and the microstructure of the product is characterized by a scanning electron microscope. The results are as follows: figure 1 It can be seen from the figure that the product has an obvious layered structure.

Embodiment 2

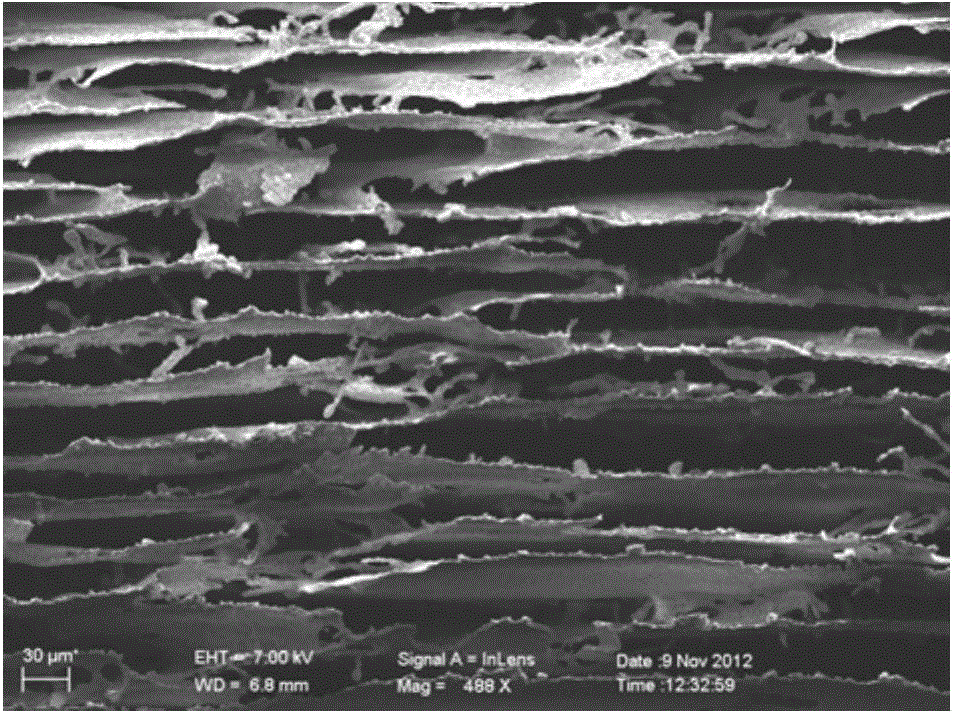

[0027] Prepare 100 mL of 20 mg / mL chitosan solution, then weigh 1 g of LDH micro-tablets (synthesized according to the literature: Colloids and Surfaces A: Physicochem. Eng. Aspects 408 (2012) 71-78) and add to the above solution, ultrasonic treatment until uniform dispersion , to obtain a mixed solution; the silicone mold (mould capacity 2 × 2 × 2cm 3 ) on the freezing surface of the stainless steel freezing device; pour 4mL of the prepared mixed solution into the mold, and then use liquid nitrogen to cool down from one end of the freezing surface to -100°C, so that the freezing point moves from one end of the freezing surface to the other. One end moves, so that the ice in the mold grows along one end of the freezing surface to the other until the solution in the entire mold is completely frozen; the ice cubes that have been frozen are placed in a vacuum freeze dryer for deicing and drying for 48 hours, The layered chitosan hydroxyapatite composite material can be obtained, ...

Embodiment 3

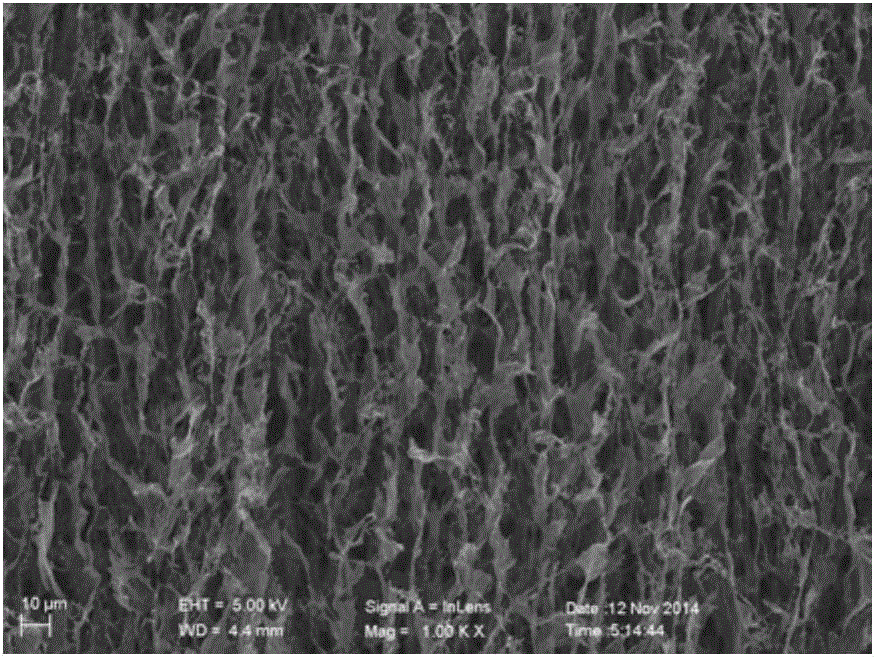

[0029] Take 6 mg / mL graphene oxide nanosheet aqueous solution (synthesized by Hummers method, Hummers, W., Jr.; Offeman, R.J.Am.Chem.Soc.1958, 80, 1339.); Silicone mold (mould capacity 2 × 2 ×2cm 3 ) is installed on the freezing surface of a stainless steel freezing device; pour 4 mL of the prepared above-mentioned graphene oxide nanosheet aqueous solution into the mold, and then use liquid nitrogen to cool down from one end of the freezing surface to -100 ° C, so that the freezing point changes from freezing to One end of the surface moves to the other end, so that the ice in the mold grows along one end of the freezing surface to the other end until the solution in the entire mold is completely frozen; the ice cubes that have been frozen are placed in a vacuum freeze dryer for detachment After ice-drying for 48 hours, the layered graphene oxide material can be obtained, and the microstructure of the product is characterized by a scanning electron microscope. The results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com