Aromatic hyperbranched polyester for nylon processing and preparation method thereof

A hyperbranched polyester and aromatic technology, applied in the field of aromatic hyperbranched polyester and its preparation, can solve the problem of inability to accurately control the degree of branching of hyperbranched polyester, high cost of solvent DMF recovery, and low thermal decomposition temperature of products, etc. problems, to achieve low cost, reduced flexibility, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

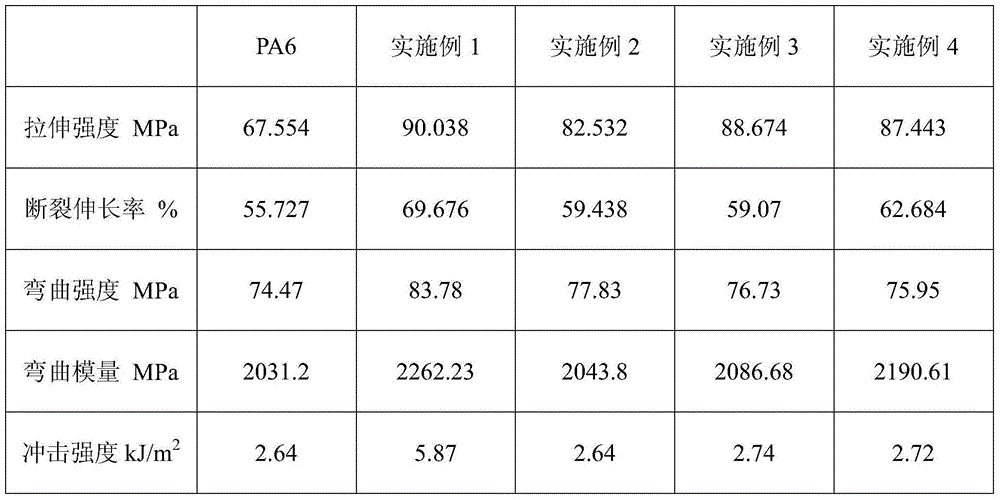

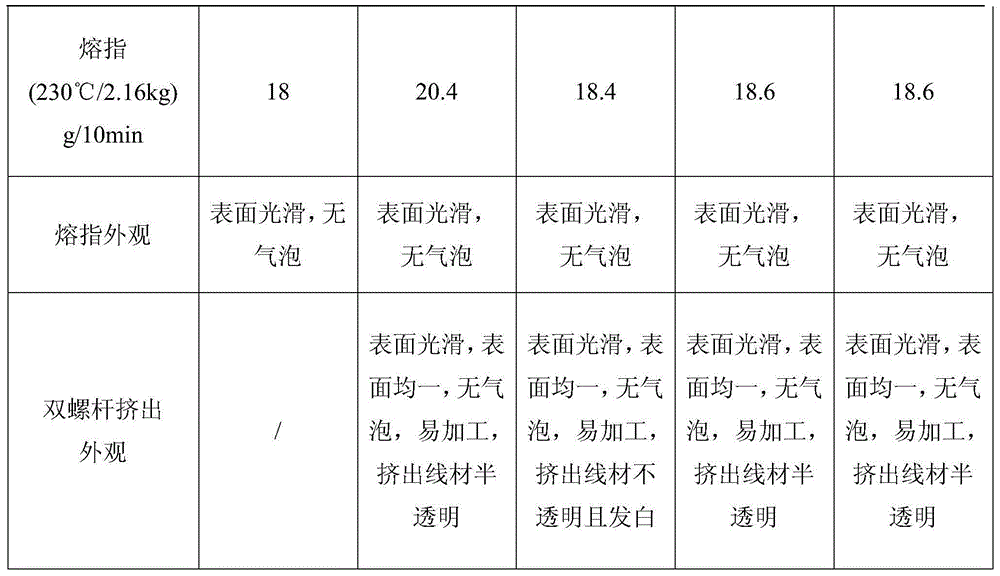

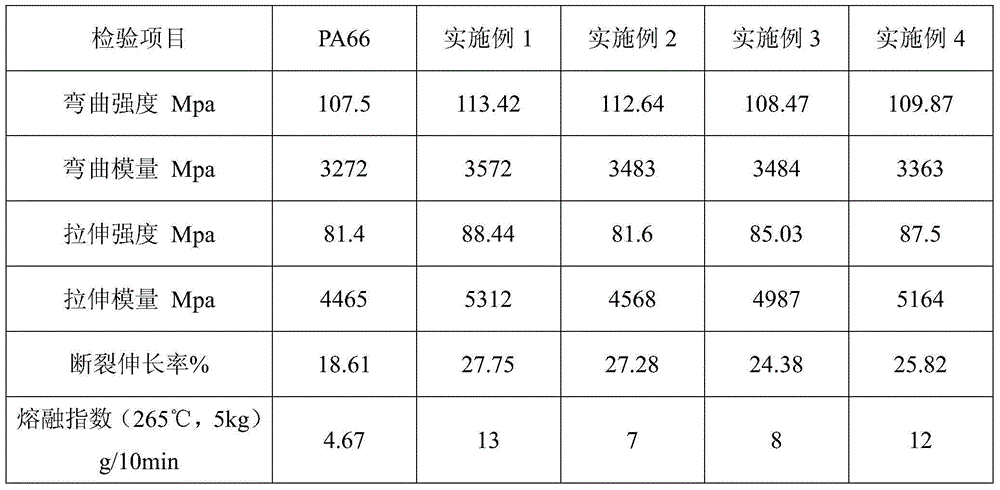

Examples

Embodiment 1

[0027] Into a 500 mL three-necked flask preinstalled with a water separator and a spherical condenser, add 45.0 g of pentaerythritol, 128.5 g of dimethyl terephthalate and 0.64 g of zinc acetate, which are uniformly mixed, and heat up to 180°C for 4 hours. After the reaction is finished, cool to room temperature and pulverize to obtain aromatic hyperbranched polyester.

Embodiment 2

[0029] Into a 500mL three-neck flask preinstalled with a water separator and a spherical condenser, add 45.0g of pentaerythritol, 64.3g of dimethyl terephthalate and 0.07g of zinc acetate, which are uniformly mixed, and heat up to 185°C for 6 hours. After the reaction is finished, cool to room temperature and pulverize to obtain aromatic hyperbranched polyester.

Embodiment 3

[0031] Into a 500mL three-neck flask preinstalled with a water separator and a spherical condenser, add 45.0g of pentaerythritol, 257.0g of dimethyl terephthalate and 2.5g of p-toluenesulfonic acid, and heat up to 190°C for 5 hours. After the reaction is finished, cool to room temperature and pulverize to obtain aromatic hyperbranched polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com