A porous silver micro-nano structure and its shape and size controllable preparation method

A technology of micro-nano structure and porous silver, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult separation, uncontrollable factors and multiple products, and achieve simple methods and accelerated catalysis Reaction, effect of multiple active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

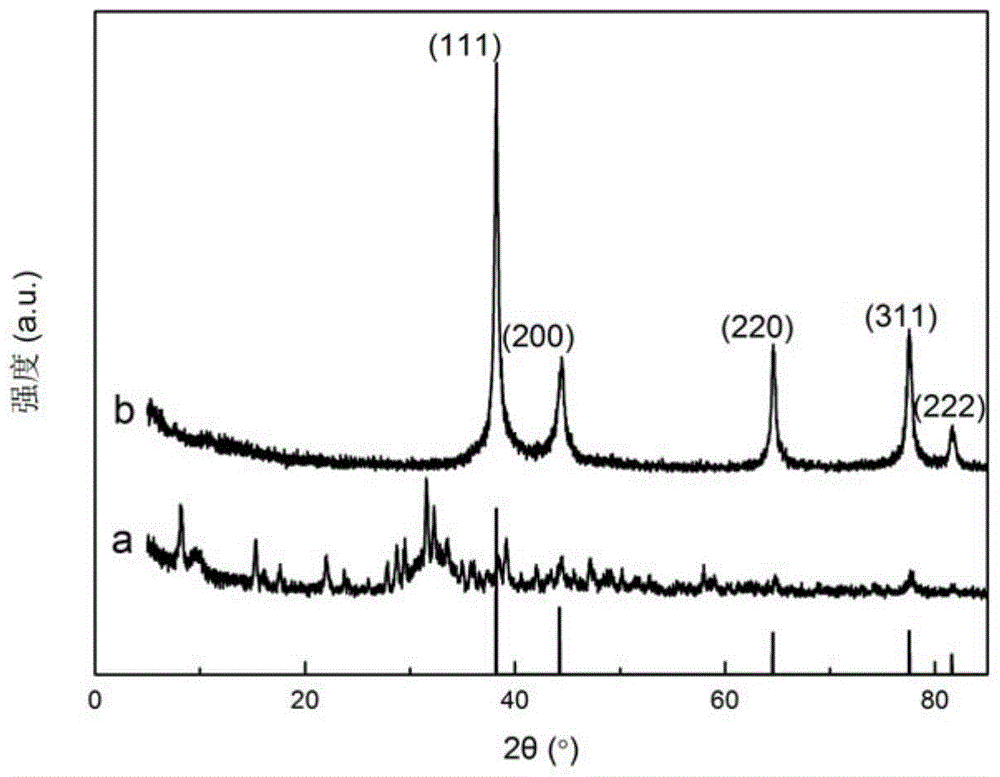

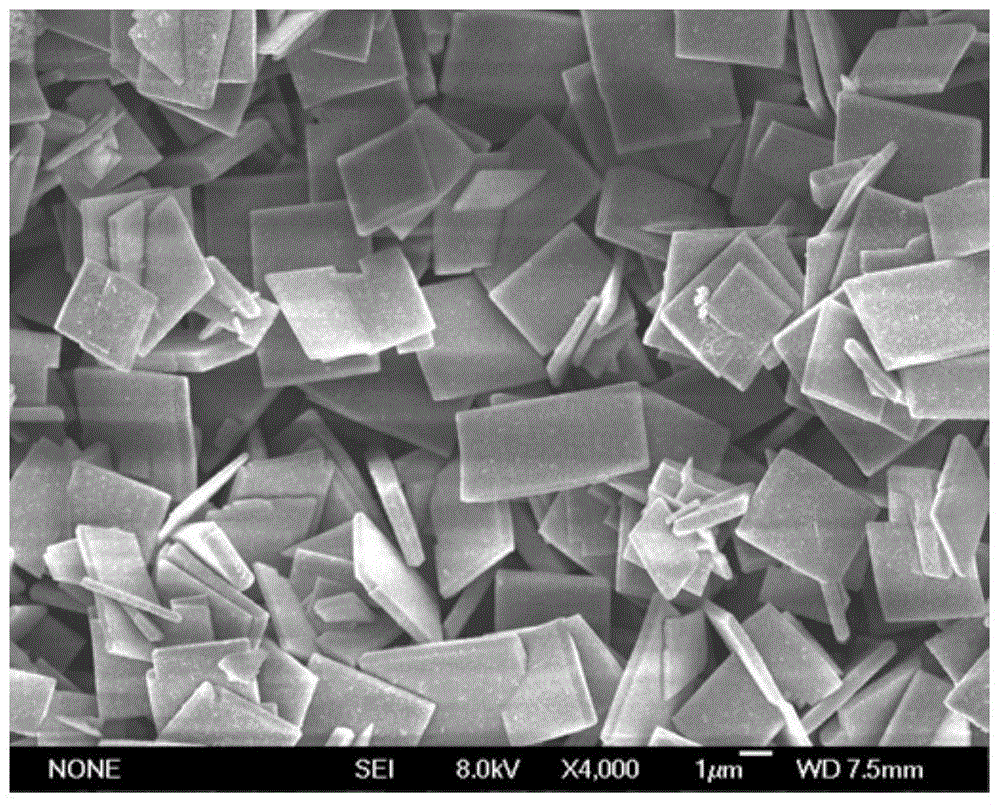

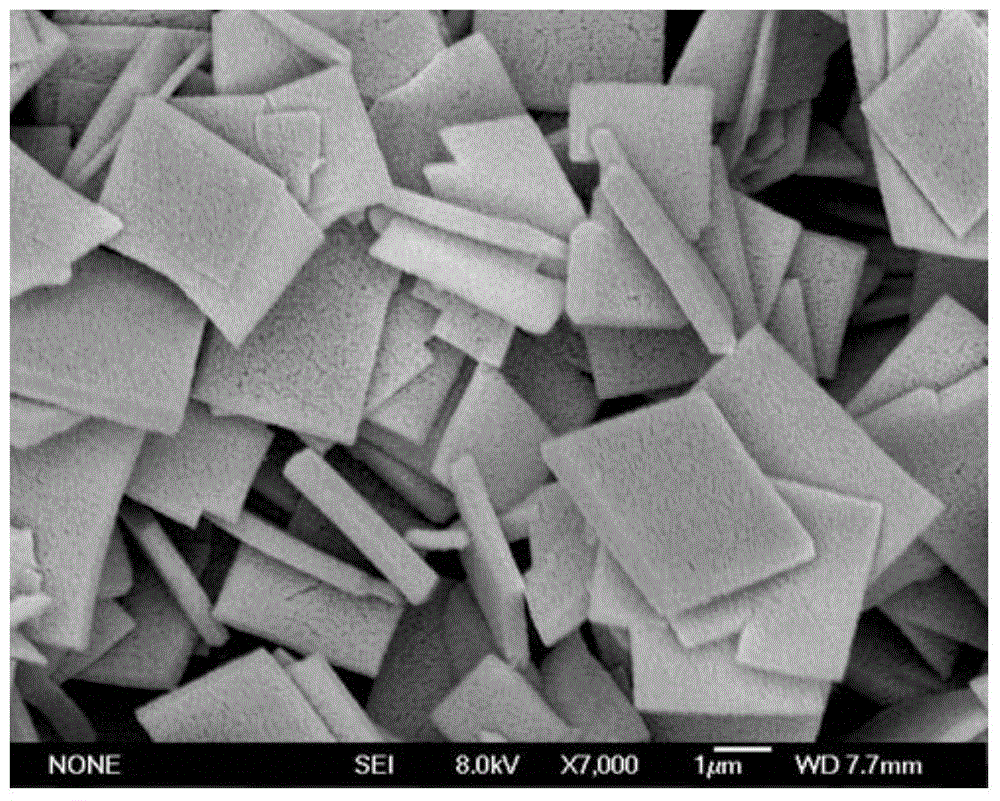

[0041] The preparation of the porous silver micro-nano structure of embodiment 1 quadrilateral

[0042] 1) Preparation of tetragonal silver micro-nanostructure precursors

[0043] Mix and dissolve 0.208 gram of sodium citrate and 0.393 gram of sodium carbonate in deionized water (the molar ratio of sodium citrate, sodium carbonate and citric acid is 2:1:0, pH is about 6.6), and the resulting mixed buffer solution is loaded into In a 250ml beaker, drip silver nitrate solution (0.357 grams of silver nitrate amount dropped in) under room temperature and magnetic stirring, white precipitate occurs when just dripping silver nitrate solution, along with the increase of the amount of silver nitrate dropped, the solution color gradually deepens. After the dropwise addition, keep stirring for 1 hour to fully react and contact, then let stand at room temperature for 8 hours, and a large amount of precipitates are formed during the precipitation process. After the precipitation, the D-...

Embodiment 2 6

[0046] Example 2 Preparation of hexagonal sandwich porous silver micro-nanostructure

[0047] The preparation process is the same as in Example 1. Just double the amount of sodium carbonate (the molar ratio of sodium citrate, sodium carbonate and citric acid is 1: 1: 0, and the pH is about 7.4). The shape of the silver micro-nano structure precursor formed when the amount of sodium carbonate added is slightly less is basically hexagonal. When the precipitation time reaches 40 hours, the hexagon also undergoes the precipitation etching process and becomes two ends. The shape of the sandwich is connected in the middle. Finally, a hexagonal sandwich porous silver micro-nano structure with a length of about 36±2 μm, a width of about 6±1 μm, and a thickness of about 1.4±0.1 μm was obtained, with a specific surface area of 175.93 m 2 / g.

[0048] Figure 5 The scanning electron micrographs of the prepared hexagonal sandwich microsheet precursor are given. Image 6 The scannin...

Embodiment 3 6

[0049] Example 3 Preparation of hexagonal sandwich porous silver micro-nanostructure

[0050] The preparation process is the same as in Example 1. Just increase the amount of sodium carbonate to 1.5 times (the mol ratio of sodium citrate, sodium carbonate and citric acid is 4:3:0, pH is about 7.1). The morphology of the silver micro-nanostructure precursor formed when the amount of sodium carbonate added is slightly less is basically hexagonal. When the precipitation time reaches 40 hours, the hexagonal shape also becomes through the precipitation etching process. The two ends are connected and the middle is a sandwich shape. Finally, a hexagonal sandwich porous silver micro-nano structure with a length of about 25±2 μm, a width of about 5±1 μm, and a thickness of about 1.0±0.1 μm with a uniform overall size was obtained, with a specific surface area of 199.06 m 2 / g.

[0051] Figure 5 The scanning electron micrographs of the prepared hexagonal sandwich microsheet precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com