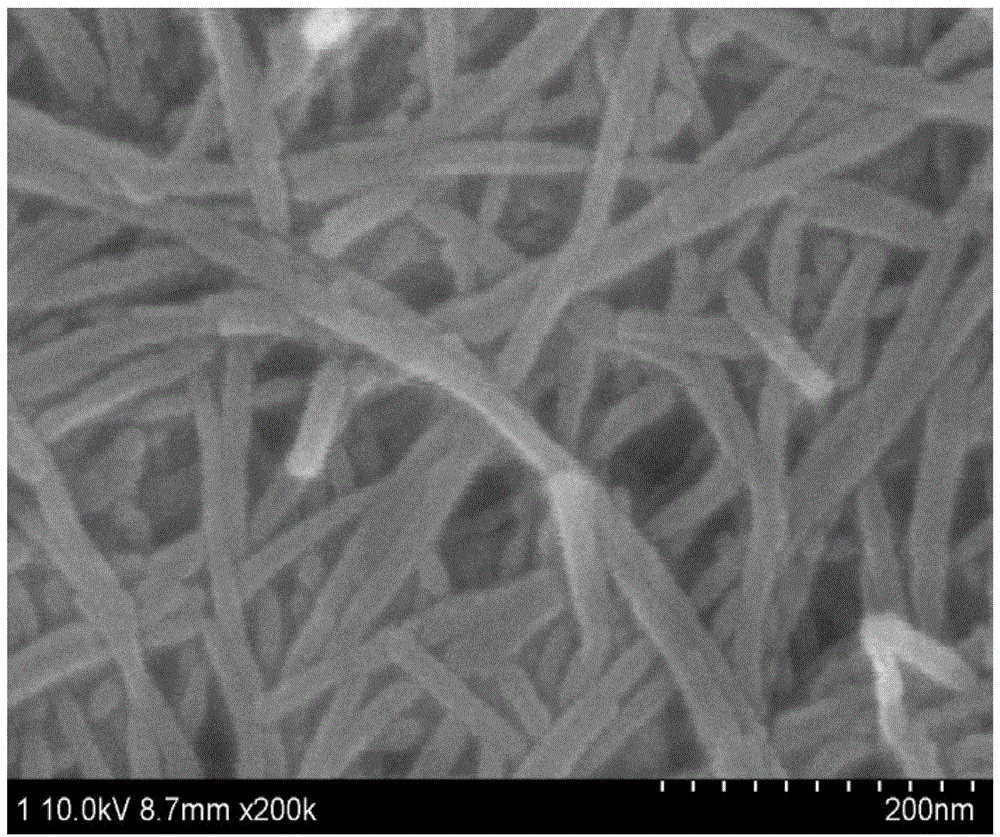

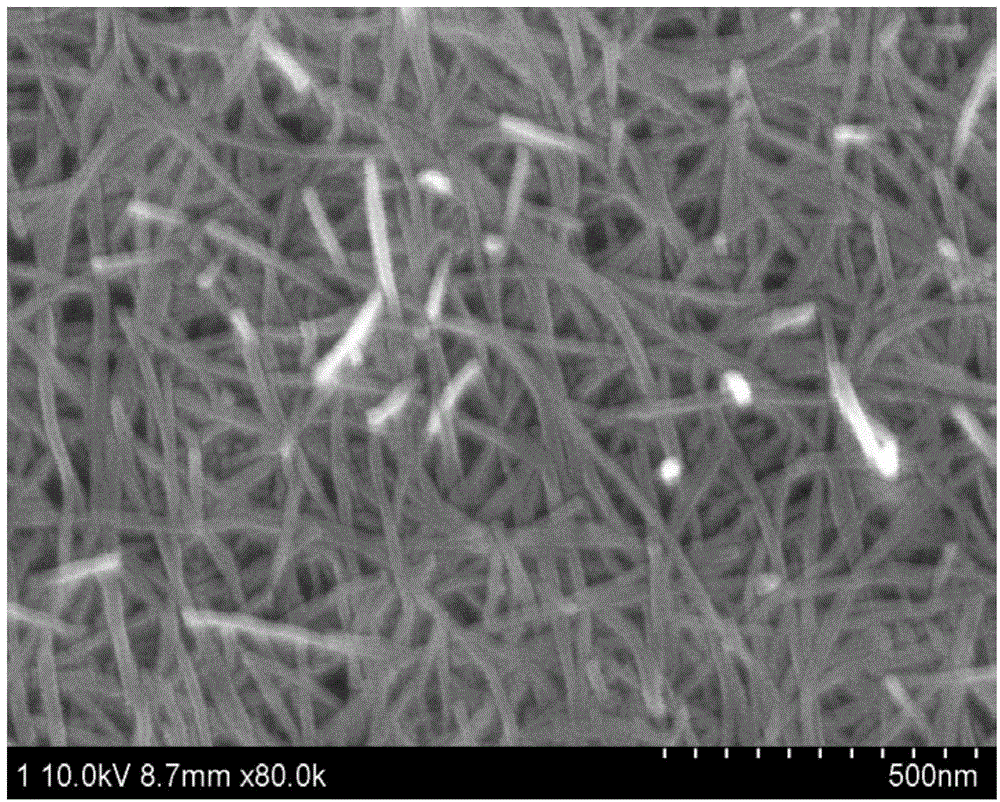

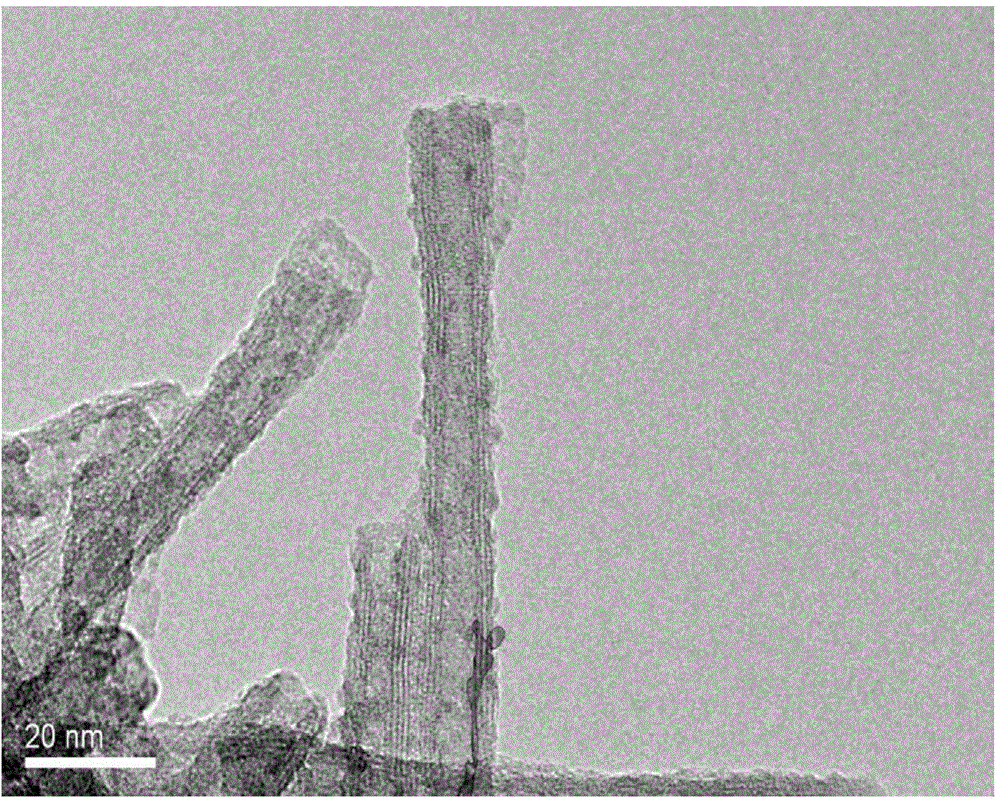

Titanium dioxide nano tube and preparation method thereof

A titanium dioxide and nanotube technology, applied in the field of preparing nanomaterials, can solve the problems of reducing the redox potential of photogenerated electrons and holes, the limitation of industrial application, and the reduction of photocatalytic performance, and achieves a wide absorption wavelength range, excellent photocatalytic effect, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of titanium dioxide nanotubes, it comprises the following steps:

[0031] 1) Solution configuration: the concentration of NaOH solution is 10mol / L, and the concentration of hydrochloric acid solution is 1moL / L;

[0032] 2) Hydrothermal reaction: Add a certain amount of commercially available titanium dioxide powder into high-concentration NaOH solution, mix ultrasonically for 15-25 minutes or magnetically stir for 2-3 hours to fully mix the two, and transfer the mixed solution to the reaction kettle. To the oven, hydrothermal reaction for a period of time;

[0033] The parts by weight of each component of the preparation method batching of described titanium dioxide nanotubes are:

[0034] NaOH solution: 95-98 parts

[0035] TiO2: 2-5 parts

[0036] Reaction temperature: 120-140°C

[0037] Response time: 32-36h

[0038] 3) Separation and washing of the intermediate: After the hydrothermal reaction in step 2), the reaction kettle is naturally co...

Embodiment 1

[0046] Embodiment 1: a kind of preparation method of titanium dioxide nanotube, it comprises the following steps:

[0047] 1) Solution configuration: the concentration of NaOH solution is 10mol / L, and the concentration of hydrochloric acid solution is 1moL / L;

[0048] 2) Hydrothermal reaction: Add 1 part of commercially available titanium dioxide powder to 95 parts of high-concentration NaOH solution in parts by mass, mix ultrasonically for 15 minutes to fully mix the two, transfer the mixed solution to the reaction kettle and move it to the oven , hydrothermal reaction at a high temperature of 120°C for 32 hours;

[0049] 3) Separation and washing of intermediates: After the hydrothermal reaction in step 2), the reaction kettle is naturally cooled to normal temperature, the intermediates are taken out, acidified with a prepared 1mol / L hydrochloric acid solution, and the pH is kept at 1.5, and the magnetic Stir with a stirrer for 24 hours, seal it with a plastic wrap, then pe...

Embodiment 2

[0052] Embodiment 2: a kind of preparation method of titanium dioxide nanotube, it comprises the following steps:

[0053] 1) Solution configuration: the concentration of NaOH solution is 10mol / L, and the concentration of hydrochloric acid solution is 1moL / L;

[0054]2) Hydrothermal reaction: Add 3 parts of commercially available titanium dioxide powder into 97 parts of high-concentration NaOH solution, stir magnetically for 3 hours to fully mix the two, transfer the mixed solution to the reaction kettle and move it to an oven, and heat it at a high temperature of 140 Hydrothermal reaction at ℃ for 34 hours;

[0055] 3) Separation and washing of intermediates: After the hydrothermal reaction in step 2), the reaction kettle is naturally cooled to normal temperature, the intermediates are taken out, acidified with a prepared 1mol / L hydrochloric acid solution, and the pH is kept at 1.5, and the magnetic Stir with a stirrer for 24 hours, seal it with a plastic wrap, then perform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com