Liquefied gas desulfurizing agent

A technology of desulfurization agent and liquefied gas, which is applied in chemical instruments and methods, processing of gas mixtures, and treatment of hydrocarbon oils. It has good synergistic effect, eliminates potential safety hazards, and has no effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

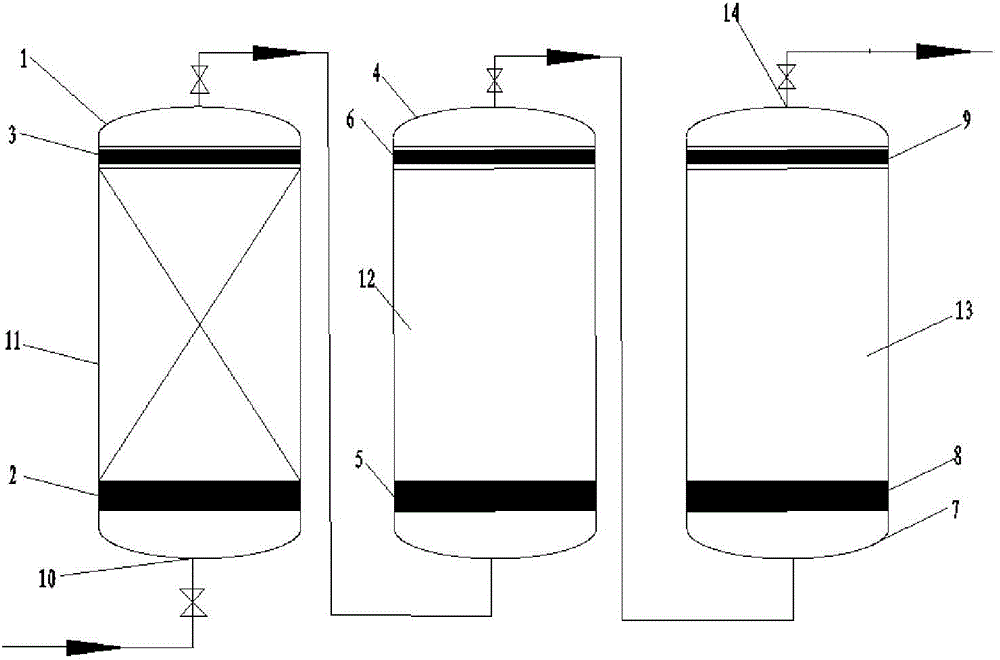

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1. Preparation of liquefied gas desulfurizer

[0041] Liquefied gas desulfurizer, composed of the following components in weight percentage: ZnO: 35-50%, MnO 2 : 35~50%, CaO: 5~15% (ZnO comes from zinc carbonate, MnO 2 It is derived from manganese carbonate, CaO is derived from calcium carbonate), and the balance is carrier, which is composed of 40-65% aluminum hydroxide and 35-60% silicon oxide.

[0042] The preparation method of the above-mentioned liquefied gas desulfurizer is operated according to the following steps:

[0043] 1) Mixing material: Add zinc carbonate, manganese carbonate, calcium carbonate, aluminum hydroxide and silicon oxide into the mixer according to the above weight ratio, and mix.

[0044] 2) Molding: Add the mixture obtained in step 1 into a molding machine for molding, curing for 24 hours, and drying.

[0045] 3) Shaping: Add the dried mixture in step 2 to the shaping machine for shaping.

[0046] 4) Activation: calcining the re...

Embodiment 2

[0047] Embodiment 2, preparation of liquefied gas desulfurizer

[0048] Liquefied gas desulfurizer, composed of the following components in weight percentage: ZnO: 35-50%, MnO 2 : 35~50%, CaO: 5~15% (ZnO is derived from active zinc oxide, MnO 2 It is derived from active manganese oxide, CaO is derived from calcium hydroxide), and the balance is a carrier, which is composed of 40-65% aluminum bohydrate and 35-60% silicon oxide.

[0049] The preparation method of the above-mentioned liquefied gas desulfurizer is operated according to the following steps:

[0050] 1) Mixing material: Add active zinc oxide, active manganese oxide, calcium hydroxide, aluminum hydroxide and silicon oxide into the mixer according to the above weight ratio, and mix.

[0051] 2) Molding: Add the mixture obtained in step 1 into a molding machine for molding, curing for 24 hours, and drying.

[0052] 3) Shaping: Add the dried mixture in step 2 to the shaping machine for shaping.

[0053] 4) Activatio...

Embodiment 3

[0054] Embodiment 3, preparation of liquefied gas desulfurizer

[0055] Liquefied gas desulfurizer, composed of the following components in weight percentage: ZnO: 35-50%, MnO 2: 35-50%, CaO: 10-20% (ZnO is derived from basic zinc carbonate, MnO 2 It is derived from manganese acetate, CaO is derived from calcium acetate), and the balance is carrier, which is composed of 40-65% of aluminum oxide and 35-60% of silicon oxide.

[0056] The preparation method of the above-mentioned liquefied gas desulfurizer is operated according to the following steps:

[0057] 1) Mixing material: Add basic zinc carbonate, manganese acetate, calcium acetate, aluminum oxide and silicon oxide into the mixer according to the above weight ratio, and mix.

[0058] 2) Molding: Add the mixture obtained in step 1 into a molding machine for molding, curing for 24 hours, and drying.

[0059] 3) Shaping: Add the dried mixture in step 2 to the shaping machine for shaping.

[0060] 4) Activation: calcining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com