A kind of resveratrol polymer bonded drug and preparation method thereof

A technology of resveratrol and macromolecular polymer, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, antibacterial drugs, etc., can solve the problem that the inclusion effect has a great influence, water solubility and stability are not involved, etc. problem, to achieve good hydrophilicity and biocompatibility, avoid phagocytosis, stability and water solubility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Add 1.9g of p-toluenesulfonyl chloride to a drying reactor with a water separator and a stirring device, pump argon 3 times, azeotropically remove water from anhydrous toluene, and after removing most of the toluene, change to a vacuum device for extraction The remaining toluene was dried under vacuum at 80°C for 6 hours. After returning to room temperature, add 3.00g of recrystallized resveratrol and 100ml of anhydrous acetone under the protection of inert gas, and add a small amount of NaHCO to the reaction. 3 , React under magnetic stirring at 25℃ for 18 hours. Filter the product to remove NaHCO 3 , The supernatant liquid was suspended and evaporated to a molten state to remove a large amount of acetone, the product was dissolved in appropriate dichloromethane, ether was settled, and dried in vacuo to obtain 4.10 g of a white powdery product with a yield of 83.7%.

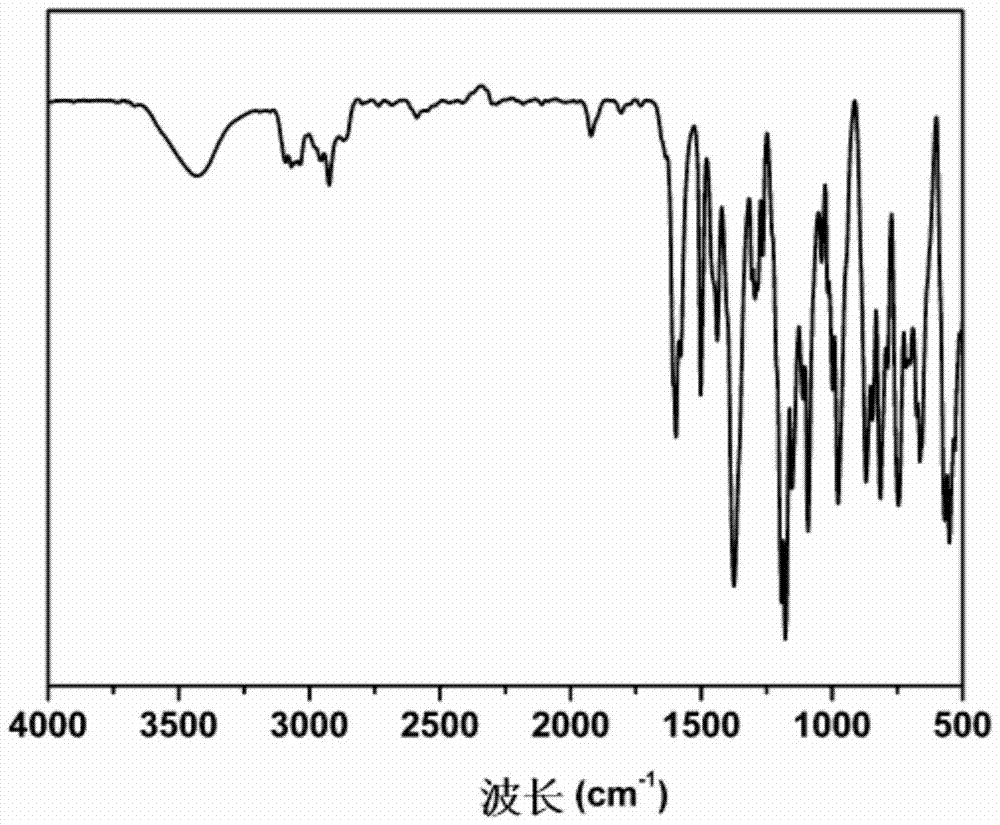

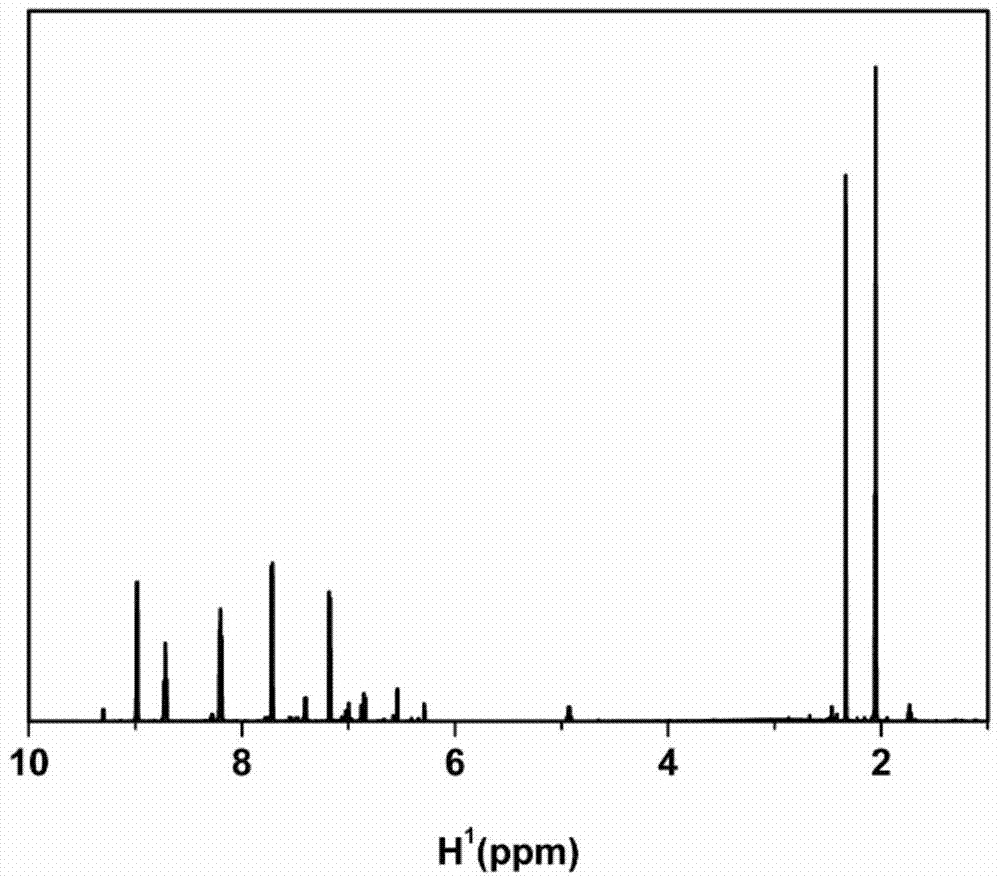

[0061] The infrared spectrum of the obtained resveratrol derivatives can be seen figure 1 , NMR spectrum ...

Embodiment 2

[0065] Add 1.90g of p-toluenesulfonyl chloride to a drying reactor with a water separation device and a stirring device, pump argon 3 times, azeotropically remove water from anhydrous toluene, and after removing most of the toluene, change to a decompression device for extraction The remaining toluene was dried under vacuum at 80°C for 6 hours. After returning to room temperature, add 3.00g of recrystallized resveratrol and 100ml of anhydrous acetone under the protection of inert gas, while adding a small amount of NaHCO to the reaction 3 , React under magnetic stirring at 25℃ for 18 hours. Filter the product to remove NaHCO 3 , The supernatant liquid was suspended and evaporated to a molten state to remove a large amount of acetone, the product was dissolved in appropriate dichloromethane, ether was settled, and dried in vacuo to obtain 4.10 g of a white powdery product with a yield of 83.7%.

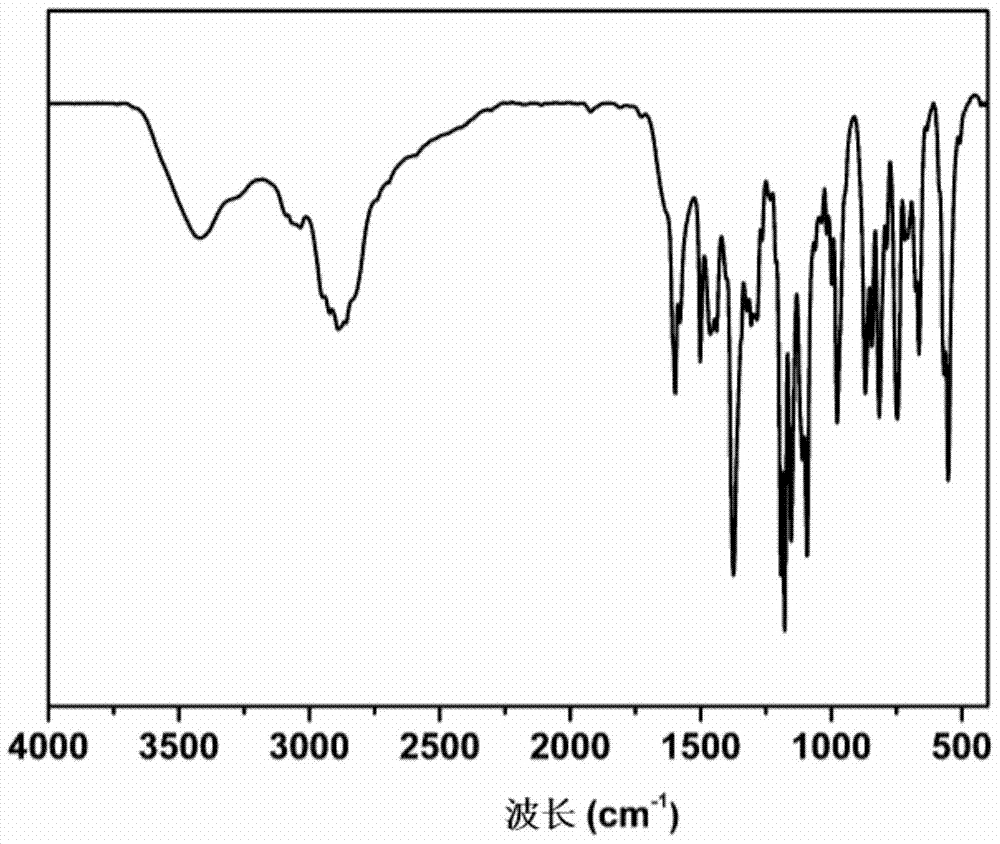

[0066] The infrared test results of the obtained synthetic product show that the prod...

Embodiment 3

[0069] Add 785 mg of acetyl chloride to a dry reactor with a water separation device and a stirring device, pump argon 3 times, soak the molecular sieve to remove water, after removing most of the water, change it to a decompression device to extract purified acetyl chloride. Under the protection of inert gas, add to 100ml of anhydrous acetone and add 3.00g of recrystallized resveratrol, while adding a small amount of NaHCO to the reaction 3 , React for 20 hours at 25℃ under magnetic stirring. Filter the product to remove NaHCO 3 , The supernatant liquid was suspended and evaporated to a molten state to remove a large amount of acetone, the product was dissolved in appropriate dichloromethane, ether was settled, and dried under vacuum to obtain 2.80 g of a white powdery product with a yield of 74.0%.

[0070] The infrared test result of the obtained synthetic product shows that the product contains both the resveratrol structure and the characteristic absorption peak of acetyl chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com