Organic light-emitting device and preparation method thereof

An electroluminescent device and luminescence technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as short service life, poor mechanical strength, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] An organic electroluminescent device is prepared through the following steps:

[0083] (1) Provide a clean anode conductive substrate:

[0084] Clean the ITO glass substrate with acetone, ethanol, deionized water, and ethanol in an ultrasonic cleaner in sequence, wash and wash for 5 minutes in one item, then blow dry with nitrogen, and dry in an oven for later use; surface activation of the cleaned ITO glass processing; ITO thickness is 100nm;

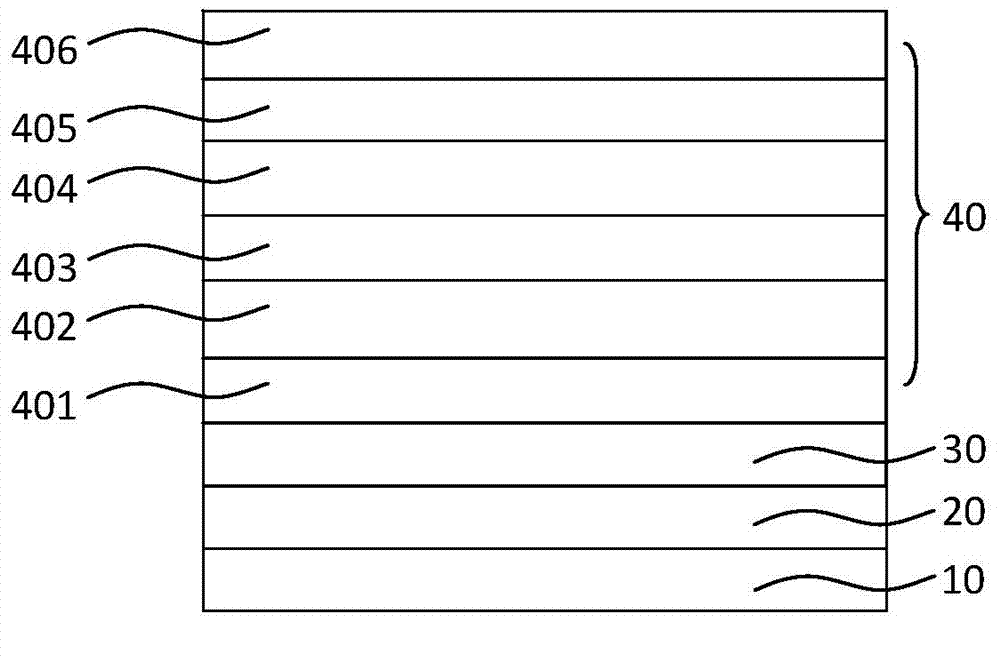

[0085] (2) Vacuum evaporation of the luminescent functional layer on the ITO glass substrate:

[0086] Specifically, the light emitting functional layer includes a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer and an electron injection layer;

[0087] Preparation of the hole injection layer: the MoO 3 The mixture obtained by mixing with NPB according to the mass ratio of 1:3 is used as the material of the hole injection layer, the thickness is 10nm, and the vacuum degree is ...

Embodiment 2

[0105] An organic electroluminescent device is prepared through the following steps:

[0106] (1), (2), (3) are the same as embodiment 1;

[0107] (4) Prepare the encapsulation layer on the outside of the cathode:

[0108] The encapsulation layer is alternately stacked silicon oxynitride barrier layers and inorganic barrier layers;

[0109] Fabrication of silicon oxynitride barrier layer: HMDS, NH 3 , O 2 As the source, argon gas was introduced, and a silicon oxynitride film was prepared in a PECVD deposition chamber to obtain a silicon oxynitride barrier layer. The preparation process conditions were HMDS flow rate 14 sccm, NH 3 Flow 18sccm, O 2 The flow rate is 18sccm, the flow rate of argon gas is 80sccm, and the thickness of the silicon oxynitride film is 190nm;

[0110] Fabrication of the inorganic barrier layer: the organic electroluminescent device sample prepared with the silicon oxynitride barrier layer was placed in the deposition chamber of the atomic layer dep...

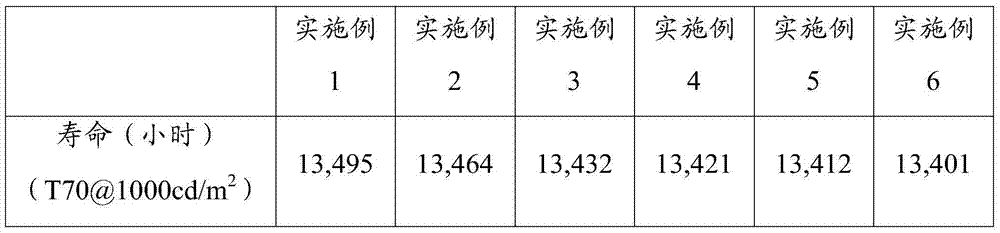

Embodiment 3

[0116] An organic electroluminescent device is prepared through the following steps:

[0117] (1), (2), (3) are the same as embodiment 1;

[0118] (4) Prepare the encapsulation layer on the outside of the cathode:

[0119] The encapsulation layer is alternately stacked silicon oxynitride barrier layers and inorganic barrier layers;

[0120] Fabrication of silicon oxynitride barrier layer: HMDS, NH 3 , O 2 As the source, argon gas was introduced to prepare a silicon oxynitride film in a PECVD deposition chamber to obtain a silicon oxynitride barrier layer. The preparation process conditions were HMDS flow rate 12 sccm, NH 3 Flow 15sccm, O 2 The flow rate is 16sccm, the flow rate of argon gas is 76sccm, and the thickness of the silicon oxynitride film is 180nm;

[0121] Fabrication of the inorganic barrier layer: the organic electroluminescent device sample prepared with the silicon oxynitride barrier layer was placed in the deposition chamber of the atomic layer deposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com