Pressure reduction device for cooling water pipeline of intermediate frequency furnace

A cooling water pipeline and decompression device technology, applied in the field of smelting alloy casting, can solve problems such as pressure increase, hidden dangers, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

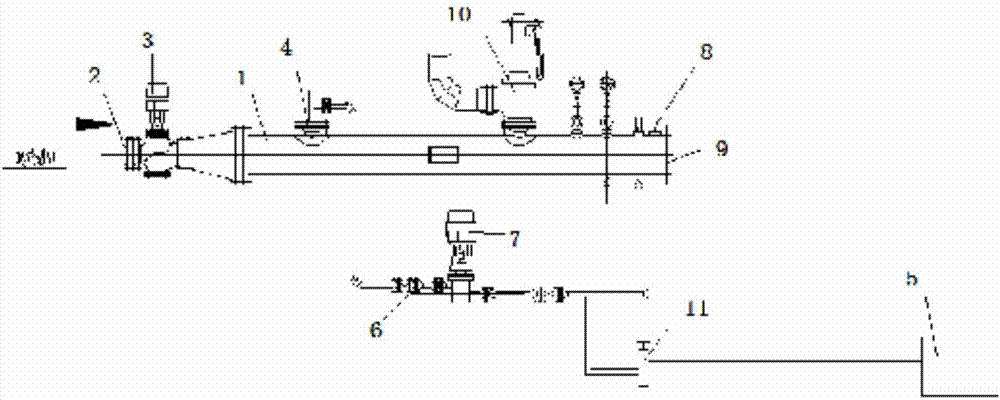

[0011] Referring to the accompanying drawings; a decompression device for the cooling water pipeline of an intermediate frequency furnace, including a cooling water circulation pipeline 1, the left end of the cooling water circulation pipeline 1 is provided with a water inlet 2, and the water inlet 2 is provided with a valve 3, so The upper surface of the middle section of the cooling water circulation pipeline 1 is provided with a spiral sprayer 4, and the spiral sprayer 4 is connected to the decompression water tank 5 through a pipeline, and a water pump is connected on the pipeline between the spiral sprayer 4 and the decompression water tank 5 6 and an electric regulating valve 7, and a pressure sensor 8 is arranged on the right end pipe wall of the cooling water circulation pipe 1.

[0012] A cooling water outlet 9 is provided at the right end of the cooling water circulation pipe 1 .

[0013] A safety valve 10 is provided at the right end of the cooling water circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com