Plant type anti-corrosion latex paint

A latex paint, plant-based technology, used in latex paints, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of poor corrosion resistance, difficult to find, low cost performance, etc. The effect of low and lower production cost

Inactive Publication Date: 2015-04-15

TIANJIN YICHENG SHUOSHEN ENVIRONMENTAL PROTECTIONDEV CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Ships sailing in the sea, sea view rooms and other buildings or ships near the ocean or in the ocean, the general latex paint cannot meet the anti-corrosion requirements in the marine climate environment, and the general anti-corrosion latex paint has poor corrosion resistance, or The cost performance is not high, it is difficult to find a latex paint that can meet the anti-corrosion requirements and is cost-effective

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

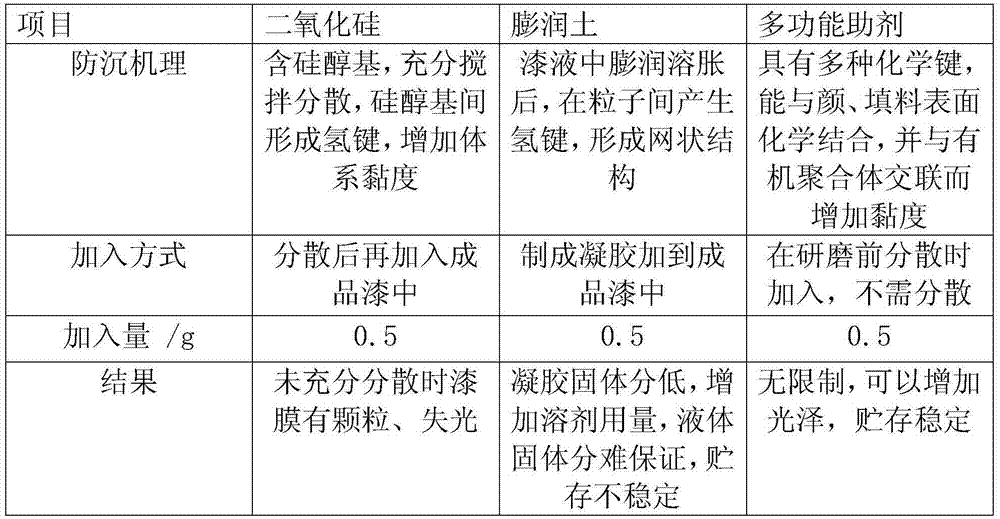

[0029] According to formula, be mixed with embodiment 1,2,3. The inorganic filler of embodiment 1 is potter's clay and talcum powder mix; The inorganic filler of embodiment 2 is mica powder and asbestos powder mix; Powder, mica powder, and asbestos powder are mixed in equal proportions.

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention provides a plant type anti-corrosion latex paint, which comprises the following raw materials, by mass, 30-50 parts of polyanion cellulose, 5-10 parts of an anti-foaming agent, 8-12 parts of a pigment, 10-15 parts of an inorganic filler, 7-14 parts of an anti-corrosion agent, 8-12 parts of a wetting agent, 1-3 parts of a perfume, 1-3 parts of a sterilization agent, 5-15 parts of a multifunctional auxiliary agent, and the balance of deionized water. The plant type anti-corrosion latex paint of the present invention has characteristics of good weathering resistance and good corrosion resistance, and is particularly suitable for harsh environments and strong corrosion environment.

Description

technical field [0001] The invention relates to the field of coatings, in particular to a plant-type anti-corrosion latex paint. Background technique [0002] Ships sailing in the sea, sea-view rooms and other buildings or ships near the sea or in the sea, the general latex paint cannot meet the anti-corrosion requirements in the marine climate environment, and the general anti-corrosion latex paint has poor corrosion resistance, or The cost performance is not high, it is difficult to find a latex paint that can meet the anti-corrosion requirements and is cost-effective. Contents of the invention [0003] In view of the deficiency of the prior art, a plant-type anti-corrosion latex paint with high cost performance is provided. [0004] In order to solve the above-mentioned technical problems, the technical scheme adopted by the present invention is: a kind of plant-type anti-corrosion latex paint, comprising the following raw materials in parts by mass: 30-50 parts of pol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D101/26C09D5/14C09D5/02C09D7/12

CPCC09D101/26C08L2205/025C08L2205/03C09D5/025C09D5/028C09D5/14C09D7/61

Inventor 杜少忠

Owner TIANJIN YICHENG SHUOSHEN ENVIRONMENTAL PROTECTIONDEV CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com