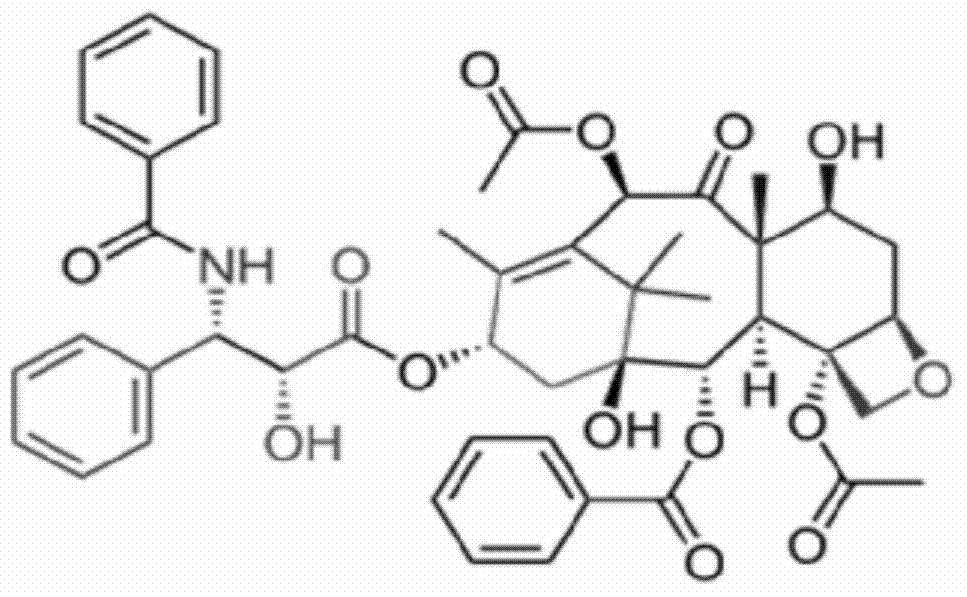

Excipient-free lyophilized paclitaxel powder preparation and preparation method thereof

A technology of paclitaxel and freeze-dried powder, applied in freeze-dried delivery, powder delivery, anti-tumor drugs and other directions, can solve the problems of large particle size and complicated process, and achieve the effects of simple formula, good solubility and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1-7

[0043] A paclitaxel freeze-dried powder preparation without excipients is prepared through the following process.

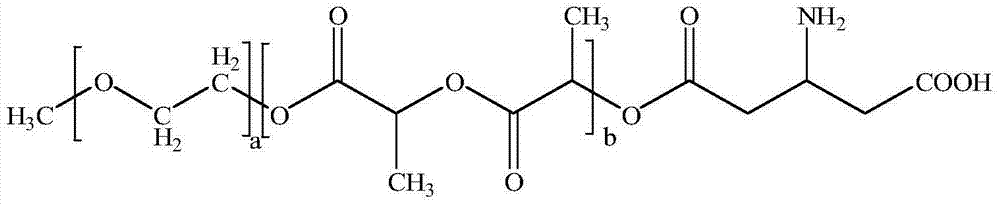

[0044]① Weigh raw materials according to different feeding ratios (paclitaxel: mPEG-PLA-glutamic acid). Among them, the raw material paclitaxel (CAS33069-62-4) is produced by Xi'an Ruilin Biotechnology Co., Ltd., the purity is greater than 95%, and the raw material mPEG-PLA-glutamic acid is produced by the inventor according to the process described in the patent number PCT-CN-2013000453 self-preparation;

[0045] ②Put the above-mentioned raw materials into a container, and add organic solvents such as ethanol or acetonitrile at a temperature of 15-45°C until they are completely dissolved. The dissolving process can adopt means such as stirring or shaking.

[0046] ③ Rotate the above solution at 30-50°C for 2 hours until the organic solvent evaporates to dryness. Then vacuum drying at 10-40° C. for > 12 hours to remove residual organic solvents to obtain a pac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com