An improved smith estimated main steam temperature control structure

A technology for controlling structure and main steam temperature, applied in temperature control, adaptive control, general control system, etc., can solve not many problems, achieve the effect of reducing dynamic deviation and facilitating engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

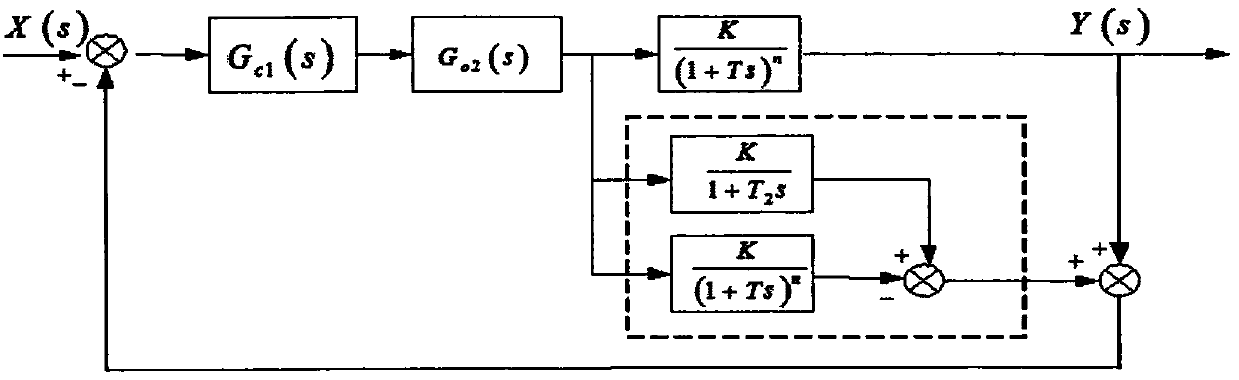

[0010] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0011] In the main steam temperature control system, the output of the temperature controller constitutes the setting value of the desuperheating water spray flow controller. Between the inlet temperature and the outlet temperature of the three-stage superheater, the steam in the pipe and the pipe wall are multiple single-capacity objects connected in series to form a multi-capacity object, so the controlled object has a large hysteresis characteristic.

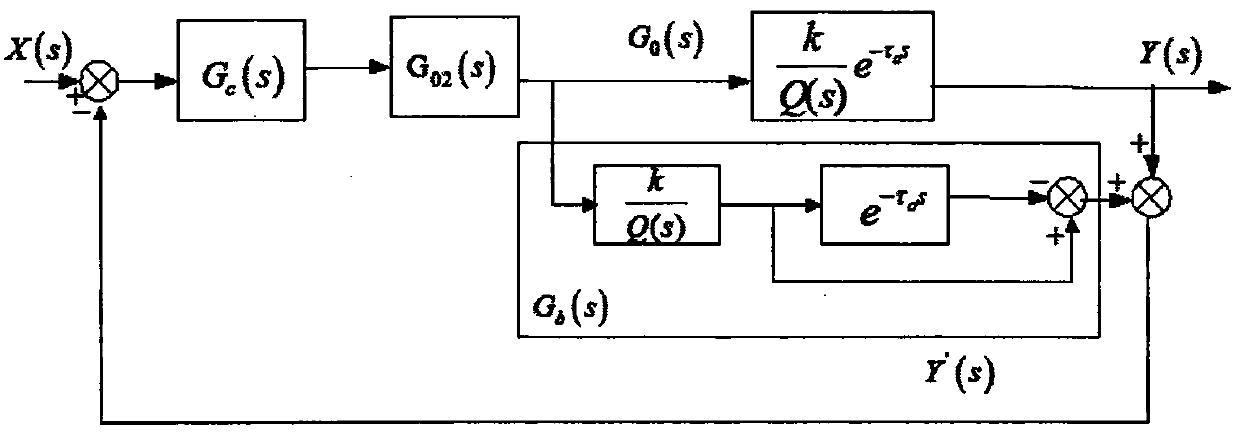

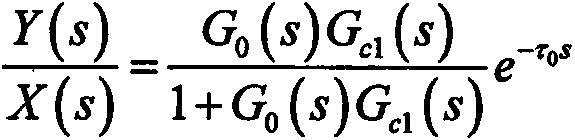

[0012] The main principle of the Smith estimator is to pre-estimate the dynamic characteristics of the controlled process under a certain disturbance, and then compensate it in advance by the Smith estimator, so that the adjusted quantity with a delay time of 0 is reflected to the controller in advance, so that The controller acts in advance, thereby reducing the overshoot of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com