Feed-forward Coal Feed Quantity Pre-control Method for Coal-fired Unit Boiler

A technology for coal-fired units and coal feeding amount, which is applied in the combustion method, adjusting fuel supply, controlling combustion, etc., can solve problems such as main steam pressure and load dynamic deviation, mismatch of pre-adding and subtracting coal feeding amount, etc. The effect of dynamic deviation, improving adaptability, and improving load control rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

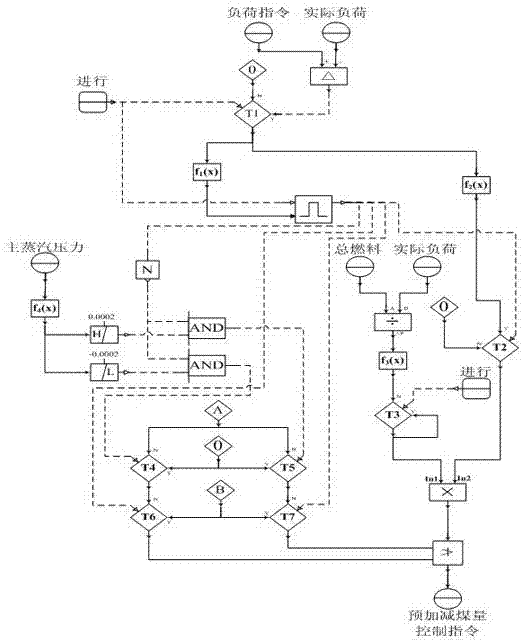

[0026] Embodiment 1: as attached figure 1 As shown, a coal-fired unit boiler feed-forward coal feed pre-control method includes the following steps:

[0027] The first step, the load triggers the signal: it is controlled by the switching module T1 whose difference between the target load instruction and the actual load is 0, and the data enters the pulse duration control function f after the switching selection 1 (x), pre-control coal feed function f 2 (x) input;

[0028] In the second step, the load performs a signal trigger pulse: f 1 (x) The output data is used to control the pulse duration, and the pulse signals are respectively output to three data switching modules T2, T6, T7 and the NOT gate;

[0029] In the third step, during the pulse period, the T2 output is controlled by the pre-control coal feed function f 2 The output of (x) is switched to 0, and the output of T2 is stored in In2;

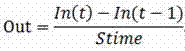

[0030] In the fourth step, the ratio of the total fuel quantity to the actual...

Embodiment 2

[0042] Embodiment 2: As shown in Tables 1, 2, and 3, the function parameter setting is introduced by taking the 300MW subcritical drum boiler unit as an example below:

[0043] Overview of related equipment of the unit: the rated power of the unit is 300MW, and the boiler is coal-fired, subcritical, natural circulation, single steam drum, single furnace, four-corner tangential combustion, one-time intermediate reheating, and balanced boiler produced by Dongfang Boiler (Group) Co., Ltd. Ventilation, close-fitting, all-steel frame, solid slag discharge, pulverized coal furnace. The steam turbine is a subcritical, one-time intermediate reheat, high and medium pressure combined cylinder, single-shaft, double-cylinder, double-exhaust, heat-supply indirect air-cooled steam turbine manufactured by Dongfang Steam Turbine Co., Ltd. of Dongfang Electric Group.

[0044] As shown in Table 1, the pulse duration control function f 1 (x) The input (In) is the deviation (MW) between the targ...

Embodiment 3

[0051] Embodiment 3: As shown in tables 4, 5, and 6, taking the 350MW supercritical once-through furnace unit as an example, the parameter setting of the introduction function:

[0052] Overview of related equipment of the unit: The capacity of the unit is 350MW, and the boiler is a single furnace, balanced ventilation, solid slag discharge, all steel frame, full suspension structure, π-type, tight-fitting closed layout, and one-time intermediate reheat produced by Harbin Boiler Factory Co., Ltd. , Supercritical pressure variable pressure operation, a once-through boiler using an atmospheric expansion start-up system without a recirculation pump. The steam turbine is a supercritical, one-time intermediate reheat, indirect air-cooled double-cylinder double-exhaust condensing steam turbine manufactured by Dongfang Steam Turbine Co., Ltd.

[0053] As shown in Table 4, the pulse duration control function f 1 (x) The input (In) is the target and actual load deviation (MW), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com