Microwave GaAs substrate on-chip S parameter microstrip line TRL (transistor resistor logic) calibrating member

A technology of microstrip lines and calibration components, which is applied in the field of microwave/millimeter wave S-parameter testing, and can solve problems such as the inability to achieve accurate measurement of microstrip line structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

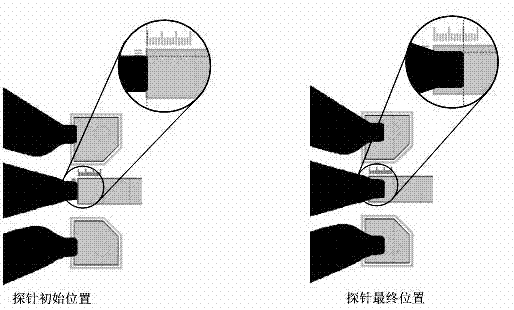

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as figure 1As shown, the present invention is an on-chip S-parameter microstrip line TRL calibrator based on a microwave GaAs substrate, comprising a GaAs substrate layer 2, the lower surface of the GaAs substrate layer 2 is connected with a metal layer 1, and the upper surface is provided with a through The graphic structure of the standard part Thru, the reflective standard part Reflect and the transmission line standard part Line, the ground pressure points 6 of the straight-through standard part Thru, the reflective standard part Reflect and the transmission line standard part Line respectively pass through the grounding column 7 and the The metal layer 1 is connected, and the GaAs substrate layer 2 is provided with a ground via hole compatible with the ground column 7; the characteristic impedance of the through stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com