Determination method of arsenic valence

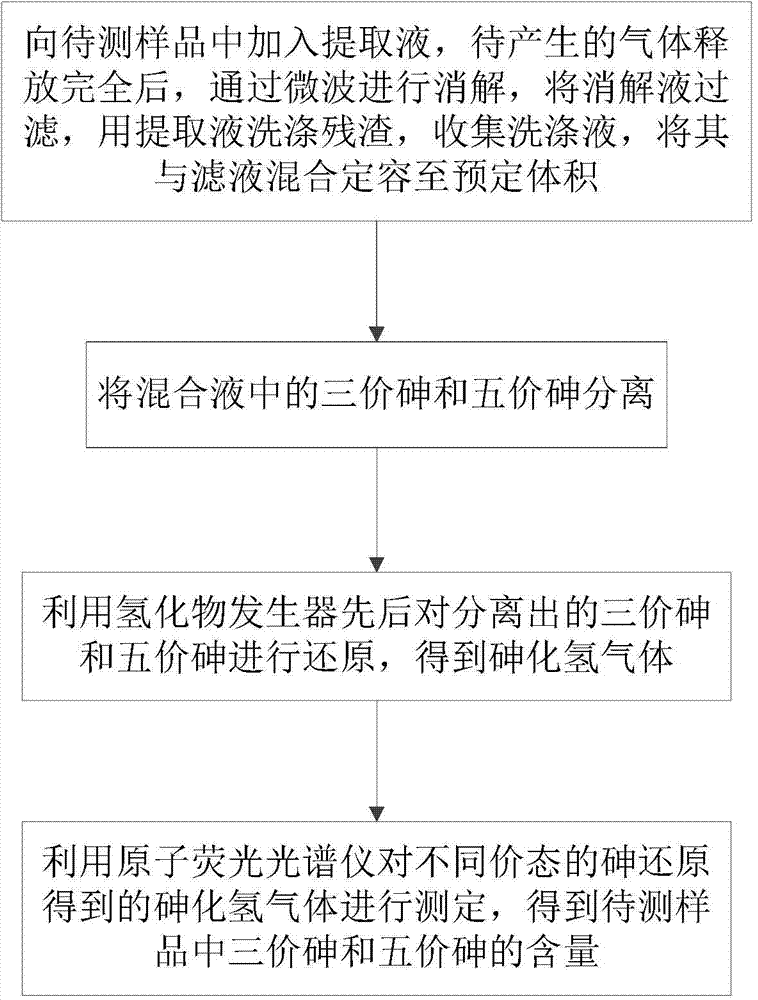

A determination method and technology of arsenic valence, which are applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of difficulty in efficient extraction of arsenic, distortion of measurement results, and difficulty in non-destructive extraction, achieving low measurement and equipment maintenance costs, High accuracy and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The assay method of arsenic valence state comprises the following steps:

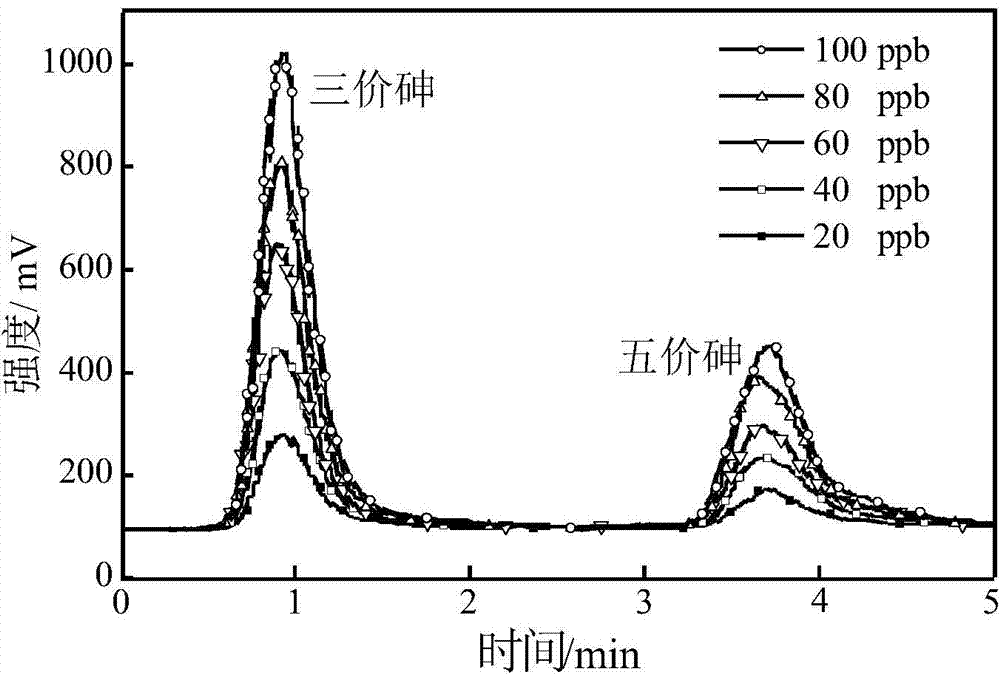

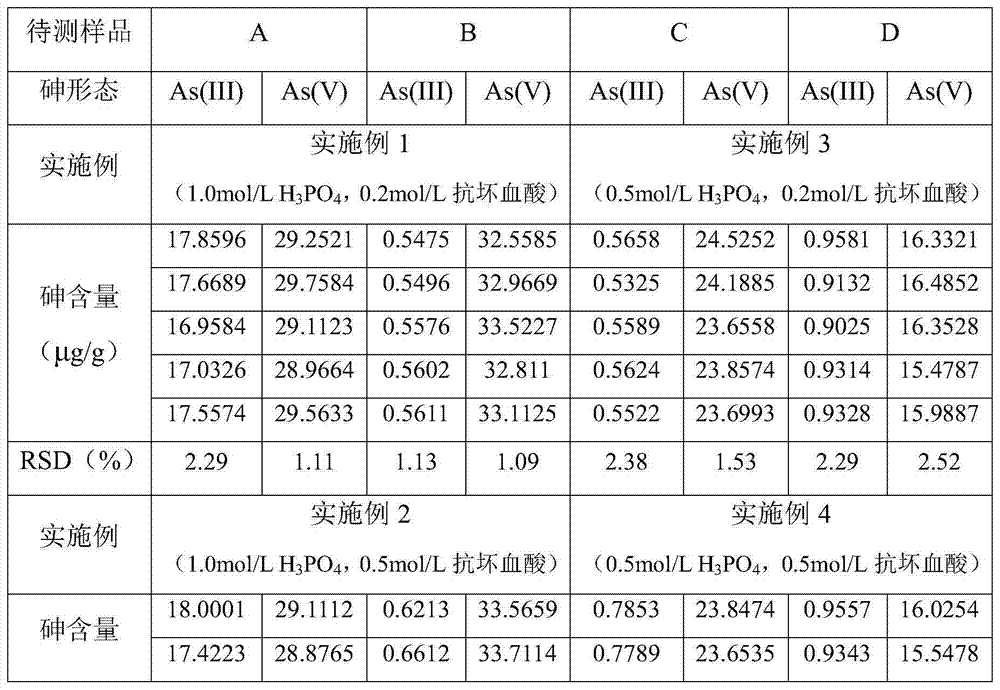

[0030] (1) Weigh 0.2g of the sample to be tested, configure H 3 PO 4 and ascorbic acid mixed solution as the extract, the H in the extract3 PO 4 The concentration of ascorbic acid is 1.0mol / L, and the concentration of ascorbic acid is 0.2mol / L; The sample to be tested is put into a Teflon digestion tank, and 20mL extract is added to the sample to be tested (solid-liquid ratio is 1:100g / mL), Place it at room temperature for 15 minutes. After the gas generated by the reaction is completely released, seal the digestion tank and put it into a microwave digestion apparatus for digestion (the digestion program is to rise from room temperature to 80°C within 10 minutes, keep warm for 20 minutes, and then naturally Cool to room temperature); filter the digestion solution and collect the filtrate; wash the residue with the extract for more than 3 times, collect the washing solution, mix it with the filt...

Embodiment 2

[0036] H in the extract 3 PO 4 The concentration of ascorbic acid is 1.0mol / L, and the concentration of ascorbic acid is 0.5mol / L, and other experimental conditions are the same with embodiment 1.

Embodiment 3

[0038] H in the extract 3 PO 4 The concentration of ascorbic acid is 0.5mol / L, and the concentration of ascorbic acid is 0.2mol / L, and other experimental conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com